The shaftless trommel screen, as a highly efficient screening equipment, is widely used in various fields such as mining, building materials, and waste treatment. Thanks to its shaftless design, it boasts significant advantages such as smooth feeding, resistance to clogging, high screening efficiency, and strong adaptability to different materials. However, during long-term, high-intensity operation, the equipment is inevitably subject to various malfunctions due to material wear, environmental corrosion, and component aging, directly affecting production progress and economic benefits. Therefore, establishing a scientific and comprehensive maintenance system, promptly identifying and resolving equipment problems, and extending the service life of the equipment are crucial for ensuring stable and efficient production. This article will detail the key points of maintenance and repair of the shaftless trommel screen, covering basic maintenance knowledge, specific maintenance content, daily maintenance system, common fault handling, and maintenance precautions.

A. Basic Understanding of Shaftless Trommel Screen Maintenance

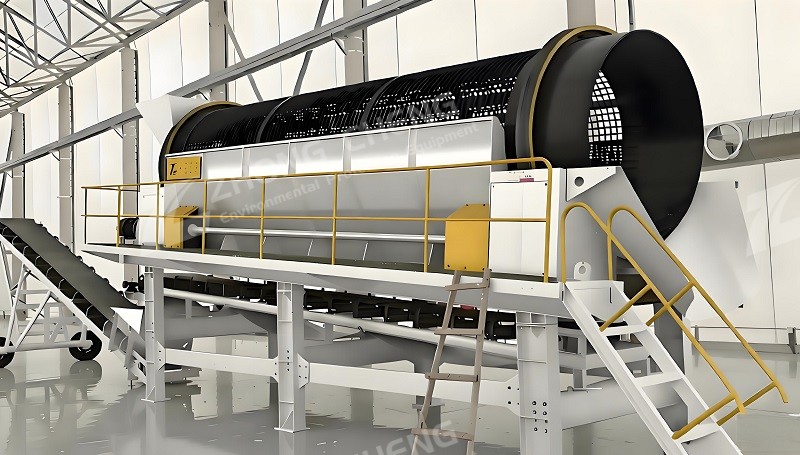

The core structure of the shaftless trommel screen mainly includes the drum body, support roller group, transmission system, frame, feed hopper, and discharge hopper. Its working principle is that the support roller group and the transmission system drive the drum body to rotate at a low speed. After the material enters from the feeding end, it moves forward under the propulsion of the spiral blades inside the drum. At the same time, with the screening action of the trommel screen, materials of different particle sizes are separated and discharged from the corresponding outlets. The core objective of maintenance is to repair damaged components and restore the equipment's technical performance, while maintenance focuses on prevention, reducing the probability of failures through regular inspection, cleaning, and lubrication. The two complement each other, jointly ensuring the stable operation of the equipment. Before carrying out maintenance work, personnel must be familiar with the equipment's structure, working principles, technical parameters, and operating characteristics, and strictly adhere to safety operating procedures to ensure the safety and effectiveness of maintenance work.

B. Specific Maintenance Content of Shaftless Trommel Screen

1. Drum Body and Screen Mesh Maintenance

The drum body and screen mesh are the core components of the shaftless trommel screen that directly contact the material, and are also the most severely worn parts. The quality of their maintenance directly affects the screening efficiency. During daily inspections, if the screen mesh is found to be damaged, deformed, or has holes, it needs to be dealt with promptly. For minor damage, welding repair can be used. First, clean the debris and rust from the damaged area, and then weld with a welding rod that matches the screen material. After welding, grind the surface smooth to ensure that it does not affect the passage of materials; if the damaged area is large or the screen is severely deformed, the screen should be replaced promptly. When replacing the screen, pay attention to the screen's fixing method to ensure a secure installation and prevent secondary damage due to screen loosening during operation. At the same time, check the roundness and straightness of the drum body. If deformation occurs due to long-term wear or material impact, correction is required, and the drum body should be replaced if necessary. In addition, the material buildup on the inner wall of the drum body should be cleaned to prevent accumulation from affecting the screening effect and equipment balance.

2. Idler Roller Group Maintenance

The idler roller group plays a vital role in supporting the drum body and the weight of the materials, and its operating status directly affects the stability and service life of the equipment. During maintenance, first check the rotational flexibility of the idler rollers. Rotate the idler rollers by hand. If there is jamming or abnormal noise, it indicates that the idler roller bearings may be worn or poorly lubricated, and the idler rollers need to be disassembled for inspection. For severely worn bearings, they should be replaced promptly, and an appropriate amount of lubricating grease should be added after replacement; if the idler roller surface shows severe wear or dents, the idler roller should also be replaced promptly to ensure even contact between the idler roller and the drum body. At the same time, check the tightening of the idler roller brackets. If the brackets are loose or deformed, tighten the bolts or correct the brackets promptly to prevent the drum body from running off-center due to idler roller positioning deviations.

3. Transmission System Maintenance

The transmission system includes components such as the motor, reducer, coupling, chain, and sprocket, which are the core power source for driving the equipment. During maintenance, focus on checking the tightness of the connections of each component. If loose bolts or slack chains are found, tighten them or adjust the chain tension promptly. Check the motor's operating status, measure whether the motor current and voltage are normal, and listen for any abnormal noises during motor operation. If overheating or abnormal noises occur, it may be due to motor bearing wear or winding failure, and timely repair or replacement is required. For the gearbox, check the oil level and quality of the lubricating oil. If the oil level is too low, replenish it promptly. If the oil quality deteriorates (becomes cloudy, develops an odor, or contains impurities), the lubricating oil must be completely replaced, and the inside of the gearbox cleaned of impurities. Also, check the gearbox for oil leaks; if leaks are found, replace the seals promptly. The coupling, as a key component connecting the motor and the gearbox, should be checked for wear and aging of its elastic pads. If damaged, replace them promptly to ensure smooth transmission and reduce impact loads.

4. Frame and Other Components Maintenance

The frame is the supporting foundation of the equipment. During maintenance, check the welded parts of the frame for cracks and deformation. If cracks are found, weld and repair them promptly, and correct any deformed parts to ensure the frame is stable. Check the feed hopper and discharge hopper for damage and material leakage. If damaged, repair them promptly. For leakage points, install sealing gaskets or perform sealing treatment to prevent material leakage, environmental pollution, and production disruption. In addition, check whether the equipment's protective devices (such as protective covers and guardrails) are intact. If damaged, repair them promptly to ensure safe operation of the equipment.

C. Daily Maintenance System for Shaftless Drum Screens

1. Daily Maintenance (Daily)

Daily maintenance is the responsibility of the operator and mainly includes: cleaning the equipment surface and surrounding debris and dust to keep the equipment clean; checking the tightness of all component connections, focusing on the bolts of the support rollers, motor, gearbox, and coupling, and tightening any loose bolts promptly; checking the screen surface for material blockage and adhesion, and cleaning it promptly to ensure unobstructed screening; checking the lubrication of the drive chain and sprockets, and adding lubricating oil if necessary; observing the equipment's operating status, listening for any unusual noises, and checking for overheating of the motor and gearbox. If any abnormalities are found, stop the machine immediately for inspection. At the same time, keep daily operation records, including operating time, material processing volume, equipment operating status, and any abnormal conditions, to provide a basis for subsequent maintenance. 2. Regular Maintenance (Weekly/Monthly/Quarterly)

Weekly Maintenance: Conduct a thorough cleaning of the equipment, focusing on cleaning the inner wall of the drum, the gaps in the screen mesh, and removing material buildup and dust from the surface of the idler rollers; check the rotational flexibility of the idler rollers and perform initial treatment on any jammed rollers; check the tension of the drive chain and adjust if necessary; check all sealing parts for leaks and promptly address any material or oil leaks.

Monthly Maintenance: Disassemble and inspect the idler roller bearings, clean internal impurities, and add new grease; check the wear of the screen mesh and repair minor damage; check the operating parameters of the motor and gearbox, measure the motor insulation resistance to ensure safe operation; check the structural integrity of the frame, feed hopper, and discharge hopper, and promptly address minor deformation and cracking.

Quarterly Maintenance: Conduct a comprehensive disassembly and inspection of the equipment, focusing on checking the roundness and straightness of the drum body, the wear of the idler rollers, and the wear of various components of the transmission system; replace aging and severely worn parts, such as bearings, seals, elastic pads, and chains; thoroughly clean the gearbox and replace the lubricating oil; conduct a comprehensive inspection of structural components such as the frame and idler roller supports, correct deformed parts, and repair welded cracks; inspect the electrical system of the equipment, clean dust from the electrical control cabinet, check wiring connections, and ensure stable operation of the electrical system.

3. Seasonal Maintenance (Annually)

Conduct seasonal maintenance based on the environmental characteristics of different seasons. In hot summer weather, focus on checking the cooling devices of the motor and gearbox to ensure good heat dissipation and prevent equipment overheating; check the viscosity of the lubricating oil, and if the viscosity decreases due to high temperature, replace it with a suitable type of lubricating oil. In cold winter weather, focus on checking the equipment's anti-freezing measures, and provide insulation for equipment components placed outdoors (such as motors and gearboxes); check the low-temperature fluidity of the lubricating oil, and replace it with lubricating oil with better low-temperature performance to prevent the lubricating oil from solidifying and affecting equipment startup and operation; check the electrical wiring of the equipment to prevent the insulation layer from cracking due to low temperatures.

D. Common Faults and Troubleshooting of Shaftless Drum Screens

1. Decreased Screening Efficiency: Common causes include screen mesh blockage, screen mesh damage, abnormal drum rotation speed, and uneven material feeding. Solutions: promptly clean clogged screen mesh, repair or replace damaged screen mesh; check the transmission system and adjust the drum rotation speed to the normal range; adjust the feeding device to ensure even material feeding.

2. Abnormal Equipment Noise: This may be caused by worn idler roller bearings, poor contact between the drum and idler rollers, loose or worn drive chains, or motor or gearbox failure. Solutions: check the idler roller bearings, replace worn bearings and add lubricant; correct the idler roller position to ensure even contact with the drum; adjust the chain tension or replace worn chains; inspect the motor and gearbox and address internal faults.

3. Motor Overheating: Causes include excessive load, worn motor bearings, winding short circuits, and poor heat dissipation. Solutions: reduce the feed rate to lower the equipment load; replace the motor bearings; check the motor windings and repair short circuit faults; clean the motor heat sink to ensure the cooling system is working properly.

4. Material Leakage: This is mainly due to poor sealing of the feed hopper and discharge hopper, or loose connection between the screen mesh and the drum. Solutions: install or replace sealing gaskets and strengthen the sealing; tighten the connecting bolts between the screen mesh and the drum, and repair damaged sealing parts.

5. Drum Body Running Off-Center: This is caused by idler roller positioning deviations, frame deformation, and uneven feeding. Solutions: correct the idler roller position to ensure the idler roller axis is parallel to the drum axis; correct the deformed parts of the frame and reinforce the frame; adjust the feeding device to ensure even material distribution.

E. Maintenance and Repair Precautions

1. Safe Operation: Before maintenance and repair, the equipment power must be switched off, and a warning sign "Do not switch on, maintenance in progress" must be displayed to prevent accidental operation and equipment startup; when working at heights, safety protection facilities must be erected and safety belts must be worn; when disassembling and installing heavy components (such as drum bodies and motors), professional lifting equipment must be used to prevent components from falling and causing injury or damaging the equipment.

2. Component Matching: When replacing equipment components, products with the same model and specifications as the original components must be selected to ensure compatibility and precision fit between components, avoiding abnormal equipment operation or increased wear of other components due to mismatched parts.

3. Lubrication Standards: Strictly select lubricating oil according to the equipment manual requirements, control the amount of lubricating oil added, avoiding excessive or insufficient lubrication; regularly replace the lubricating oil to ensure its cleanliness and prevent impurities from entering the lubrication parts and affecting the lubrication effect.

4. Record Keeping and Archiving: Establish a comprehensive maintenance and repair archive, meticulously recording the time, content, replaced components, faults encountered, and treatment results of each maintenance and repair, providing data support for the equipment's entire lifecycle management, facilitating subsequent analysis of equipment failure patterns, and optimizing maintenance and repair plans.

5. Personnel Training: Regularly provide professional training to operators and maintenance personnel to improve their understanding of equipment structure principles, operating procedures, and maintenance skills, ensuring the professionalism and standardization of maintenance and repair work, and reducing equipment failures caused by improper operation or maintenance errors.

The maintenance and repair of the shaftless drum screen are crucial for ensuring stable and efficient equipment operation. Companies should establish and improve maintenance management systems, clarify the responsibilities of personnel in each position, organically combine daily maintenance, regular maintenance, and seasonal maintenance, and promptly identify and address potential equipment failures. At the same time, strengthen the professional training of maintenance personnel, standardize maintenance and repair procedures, and properly archive maintenance and repair records. Through scientific and reasonable maintenance and repair, not only can the service life of the equipment be effectively extended, reducing equipment failure rates and maintenance costs, but also production efficiency can be improved, creating greater economic benefits for the enterprise.

Save Time! Get A Detailed Quotation Quickly.