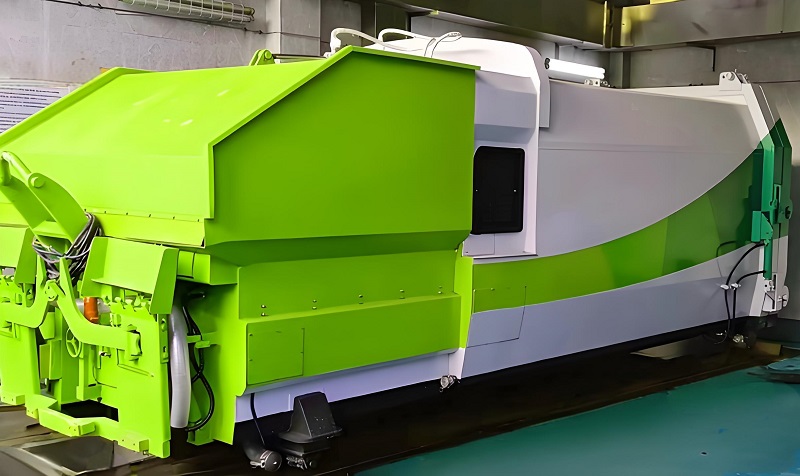

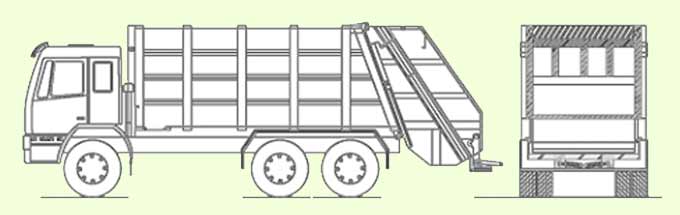

Mobile compressed garbage container is a garbage collection container that integrates automatic collection, compression, and temporary storage of garbage. It is matched with a detachable container garbage collector to achieve the transportation and self unloading of garbage. It occupies a small area, does not require civil engineering, is economically applicable, has a fast pressing speed, high compression ratio, and is suitable for the collection and transportation of various municipal solid waste (MSW).

The mobile compressed garbage container mainly consists of the container body, container cover garbage hopper, and power cabin, suitable for collecting MSW in commercial areas, industrial areas, residential areas, public places, rural areas, and townships with a daily output of less than 80 tons.

When the filling hopper is filled with garbage, the scraper opens and the skateboard drives the scraper to move downwards, inserting it into the garbage for shredding and initial compression; The scraper rotates forward to further compact the garbage; After the scraper is in place, move upwards with the skateboard, compact and fill the garbage into the garbage container, and return to the starting position. The entire working process is automatically controlled. During the continuous filling process of garbage, the push shovel overcomes the back pressure and gradually moves back under the squeezing force, making the garbage evenly fill the entire garbage container.

When purchasing a mobile garbage baler, you need to consider multiple factors to ensure that you choose the equipment that best suits your needs. Here are some specific purchase suggestions:

1. Consider the type of garbage: Determine the type of garbage that needs to be packaged, such as domestic garbage, waste paper, waste plastic, waste metal, etc. Different types of garbage have different performance requirements for balers.

2. Consider the processing volume: Select the model and specifications of the baler according to the amount of garbage that needs to be processed every day or month. Machines that are too large or too small may cause waste of resources or inefficiency.

3. Consider the working environment: Consider the working environment of the baler, such as space size, ground conditions, etc., to select a suitable mobile garbage baler.

4. Consider the packaging capacity: Pay attention to the amount of garbage that can be processed per unit time, which directly affects work efficiency.

5. Stability and durability: Examine the material, structural design and quality of key components of the machine to ensure that the equipment can operate stably for a long time and reduce failure rate and maintenance costs.

Adopting PLC intelligent control system, with low failure rate and long service life, it has functions such as oil temperature, oil level, overload, garbage detection and protection.

Large oil cylinder design, high compression efficiency, large one-time garbage collection capacity, reducing transportation frequency and transportation costs.

Differential oil circuit design ensures fast operation of the filler when unloaded, saving pressing time.

The flipping hopper and bucket rack adopt a four link mechanism, with smooth movement and no littering during the flipping and dumping process.

The working principle of Mobile Compressed Garbage Container is mainly based on hydraulic drive and special mechanism to realize the loading, compression and unloading of garbage. The following is a detailed analysis of its working principle:

1. Loading garbage

Mobile compressed garbage containers are usually equipped with special hoppers or collection ports for receiving garbage.

When the garbage is put into the hopper, the hydraulic drive system is started by operating the control system (such as PLC control system or remote control intelligent control system).

The hydraulic oil enters the cylinder through the relevant pipelines, drives the cylinder to work, and then drives the relevant mechanism (such as push plate or pressure plate) to push or press the garbage in the hopper into the container.

2. Compressing garbage

The compression process is also completed by hydraulic drive. Under the push of the cylinder, the pressure plate or push plate continuously compresses the garbage in the container.

During the compression process, the volume of the garbage gradually decreases and the density increases, thereby effectively reducing the space occupied by the garbage and facilitating subsequent transportation and storage.

The compression cycle time is usually between 25-30 seconds, depending on the model and performance of the equipment.

3. Unloading garbage

When the garbage is fully compressed and needs to be transported, the unloading mechanism is started by operating the control system.

The unloading mechanism is also driven by hydraulics, and the cylinder extends to push the unloading push plate (welded by steel plates and brackets, positioned by guide grooves) to move, thereby pushing the compressed garbage out of the container.

The unloading process is usually relatively fast, and the unloading time is generally about 40 seconds.

4. Control system

The mobile compressed garbage container is equipped with advanced control systems, such as PLC control systems and remote control intelligent control systems.

These systems make the operation of the equipment simpler and more convenient, and improve work efficiency and safety.

5. Flexibility and mobility

The biggest advantage of the mobile compressed garbage container is its flexibility and mobility.

The equipment can be moved at any time to meet the needs of different occasions and environments.

This makes the equipment widely used in various occasions such as towns and cities.

In summary, the Mobile Compressed Garbage Container realizes the loading, compression and unloading process of garbage through hydraulic drive and special mechanisms, with the advantages of high efficiency, convenience and flexibility.

Brand | CLW | Usage | Compression type |

Condition | Brand new | Capacity | 10 m³ |

Curb weight | 5.5t-5.7t | Compression cycle time | ≤45s |

Flip mechanism lifting weight | 1000kg | Storage bin volume | 3m³ |

Hydraulic oil tank capacity | 60L | Compaction density | 0.75-0.85t/m³ |

Hydraulic system pressure | 20Mpa | Compression head cross section size | 1950*500mm |

Feed port size | 2000*1420mm | power supply | 380v |

Control | PLC intelligent control | Operation | Remote control + touch screen + button |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.