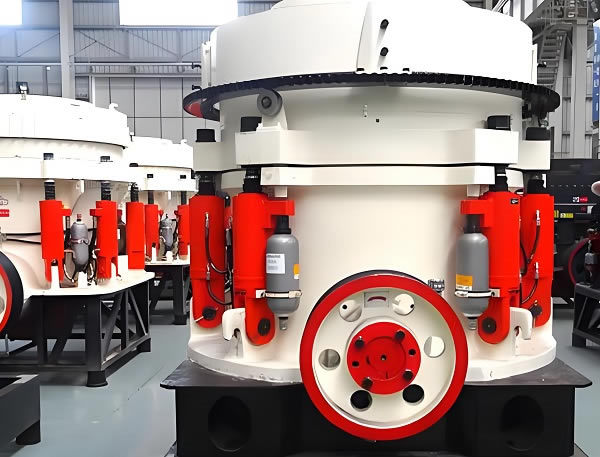

Multi-cylinder cone crusher is an efficient and stable crushing equipment, widely used in environmental protection, mining, metallurgy, construction, chemical industry and other industries. Its characteristics are that it adopts a multi-cylinder structure, through the synergy of multiple cylinders, it can fully crush the material and improve the crushing efficiency and output. Multi-cylinder cone crusher has become the preferred equipment in the crushing industry with its advantages of high efficiency, stability and wear resistance.

The multi-cylinder cone crusher is an efficient and advanced crushing equipment, which is widely used in environmental protection, mining, metallurgy, construction, chemical industry and other fields. The following is a detailed introduction to the multi-cylinder cone crusher:

When the multi-cylinder cone crusher is working, the material enters the crushing chamber and is affected by the high-speed rotating cylinder and impact force. After multiple impacts, collisions and frictions, it is finally crushed into the material of the required particle size. The whole process is carried out sequentially along the inner wall of the crushing chamber to ensure the crushing efficiency and product quality.

1. Structural features

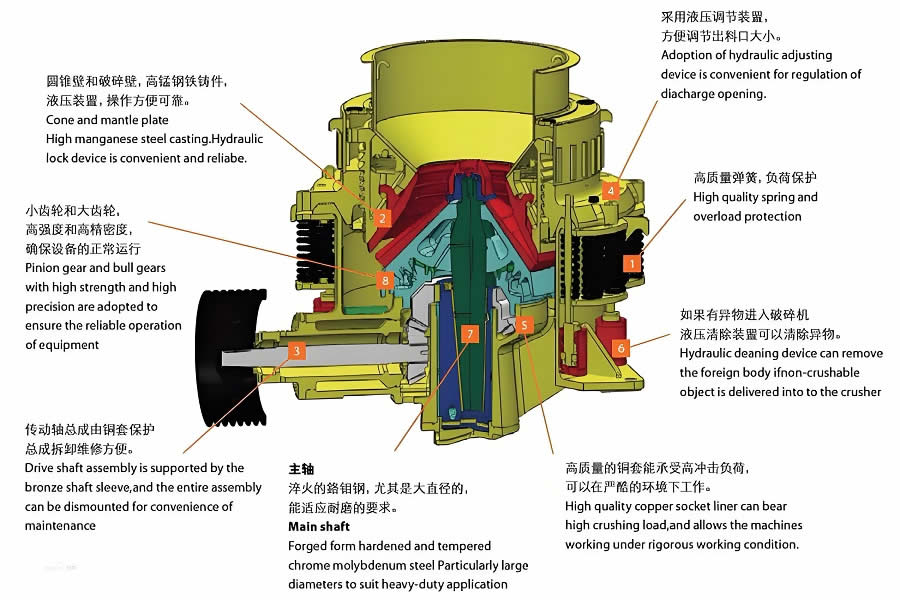

a. Multi-cylinder structure: The multi-cylinder structure is adopted, and the synergy of multiple cylinders is used to achieve full crushing of the material, improve the crushing efficiency and output.

b. Crushing chamber design: The crushing chamber is uniquely designed and made of high-wear-resistant materials, which can effectively extend the service life of the equipment.

c. Intelligent control system: The multi-cylinder cone crusher is also equipped with an intelligent control system, which can monitor the operating status of the equipment in real time, automatically adjust the crushing parameters, and ensure the stable operation of the equipment.

2. Performance advantages

a. High efficiency and energy saving: The high-efficiency transmission system and optimized design structure are adopted to improve work efficiency and reduce energy consumption.

b. High quality of finished products: The finished stone products processed by the multi-cylinder cone crusher are of high quality and uniform particle size, meeting diverse needs.

c. Safe and reliable: The equipment is equipped with safety protection devices such as overload protection and hydraulic system protection to ensure safe and reliable operation.

d. Easy to maintain: The equipment has a simple structure, is easy to maintain and overhaul, and reduces downtime and maintenance costs.

PS: Multi-cylinder cone crushers occupy an important position in the crushing industry with their advantages such as high efficiency, stability, wear resistance and easy maintenance. Multi-cylinder cone crushers have become the preferred equipment in the crushing industry with their advantages such as high efficiency, stability and wear resistance.

1. The multi-cylinder hydraulic cone crusher is equipped with a hydraulic motor, which can automatically adjust the mine opening, and automatically remove the fixed cone and the movable cone.

2. If the multi-cylinder hydraulic cone crusher stops under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing the downtime.

3. The special thin oil lubrication system design of the multi-cylinder hydraulic cone crusher improves the lubrication performance of the equipment and prolongs the service life of the equipment.

4. The special crushing chamber designed by the principle of intergranular lamination and the matching speed can realize selective crushing of materials, and the crushing particle size is uniform.

5.If conditions permit, one can visit the supplier's production base or user site for inspection to understand the actual operation of the equipment and the user's experience.

When choosing a multi cylinder cone crusher, it is necessary to comprehensively consider multiple factors such as production demand, material characteristics, crushing effect, equipment performance, energy consumption and maintenance costs, as well as technical support and service capabilities. By comprehensively evaluating and comparing different brands and models of equipment, one can choose the most suitable multi cylinder cone crusher for their production needs.

Laminated crushing brings good product shape. It improves the quality of finished product and decreases the cost of equipment and whole system.

Higher crushing efficiency with optimized crushing chamber. Several standard crushing chambers are available for each model.

The cylinder with hydraulic system provides overload and non-broken material protection. It saves the time of maintenance and decreases the operation cost.

Integrated hydraulic lubricating system with compact structure, small volume, saving installation space, reducing fuel consumption.

When the multi cylinder hydraulic cone crusher is in operation, it performs a swinging motion along the inner surface, squeezing and bending the material near the moving cone to achieve the crushing effect. The crushed material is subjected to gravity and continuously rotates and crushes from the cone downwards. The locking protection cylinder is used for iron protection and cleaning of the crushing chamber. Two hydraulic cylinders are equipped with a buffer accumulator to prevent the adjustment ring from jumping and impacting due to a small amount of hard material during the crushing process.

Cone crusher is a compression type of stone crusher. The feeding rock is crushed by squeezing or compressing the feed material between a wear resistant mantle and a manganese concave or a bowl liner.

The whole working process of HPC multi-cylinder hydraulic cone crusher is that motor drives the rotation of transmission shaft by belt pulley and v-belts, then transmission shaft drives the rotation of eccentric sleeve around the main shaft through the spiral bevel gear, squeezing or compressing the materials continuously. The material is crushed from all directions, crushed and grinded according to their own grain, which formed the high compressive strength building aggregates. The materials are small enough to fall through the narrow opening at the bottom of the crusher.

| Model | Cavity | Standard type | Shorthead type | Capacity (t/h) | Motor Power (kw) | ||

Feeder opening size(mm) | Outlet setting size(mm) | Feeder opening size(mm) | Outlet setting size(mm) | ||||

| ZMC200 | Coarse | 185 | 19 | 76 | 10 | 145-250 | 132-200 |

| Medium | 125 | 17 | 54 | 6 | 135-235 | ||

| Fine | 95 | 13 | 23 | 6 | 115-220 | ||

| UltrafineFine | 75 | 10 | 10 | 5 | 90-190 | ||

| ZMC300 | Coarse | 210 | 20 | 75 | 10 | 190-380 | 180-250 |

| Medium | 150 | 15 | 50 | 8 | 175-320 | ||

| Fine | 105 | 10 | 20 | 6 | 145-280 | ||

| UltrafineFine | 80 | 10 | 20 | 6 | 110-240 | ||

| ZMC400 | Coarse | 250 | 25 | 90 | 10 | 285-560 | 280-355 |

| Medium | 195 | 20 | 50 | 8 | 250-490 | ||

| Fine | 110 | 14 | 40 | 6 | 180-345 | ||

| UltrafineFine | 90 | 10 | 30 | 6 | 135-320 | ||

| ZMC500 | Coarse | 285 | 25 | 90 | 13 | 400-790 | 355-450 |

| Medium | 200 | 20 | 55 | 10 | 335-610 | ||

| Fine | 133 | 16 | 40 | 8 | 280-460 | ||

| UltrafineFine | 95 | 13 | 35 | 6 | 180-435 | ||

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.