The vertical compound crusher is an efficient and multifunctional crushing equipment, which integrates the advanced technologies of similar crushers at home and abroad and optimizes the main technical parameters. The equipment has the characteristics of simple and reasonable structure, low operating cost, high crushing rate, energy saving, and both fine crushing and coarse grinding. It is particularly suitable for environmental protection, building materials, mining and other industries. The vertical compound crusher adopts a screen-free design, adjustable fine crushing, uniform product particle size, low working noise, and less dust pollution. It is an indispensable crushing equipment in modern industry.

The vertical compound crusher is an efficient and multifunctional crushing equipment, which integrates the advanced technology of similar crushers at home and abroad and optimizes the main technical parameters. The equipment has the characteristics of simple and reasonable structure, low operating cost, high crushing rate, energy saving, and both fine crushing and coarse grinding. The following is a detailed introduction:

1. Basic concept and characteristics of vertical compound crusher

Vertical compound crusher is a kind of non-screen, adjustable fine crushing equipment optimized and designed on the basis of absorbing advanced fine crushing equipment at home and abroad. It is particularly suitable for building materials, mining, chemical industry, metallurgy, cement, coal and other industries, and is used to crush brittle materials with medium hardness and low water content, such as limestone, clinker, coal, etc. The vertical compound crusher has the characteristics of simple and reasonable structure, low operating cost, high crushing rate, energy saving, and both fine crushing and coarse grinding.

2. Working principle of vertical compound crusher

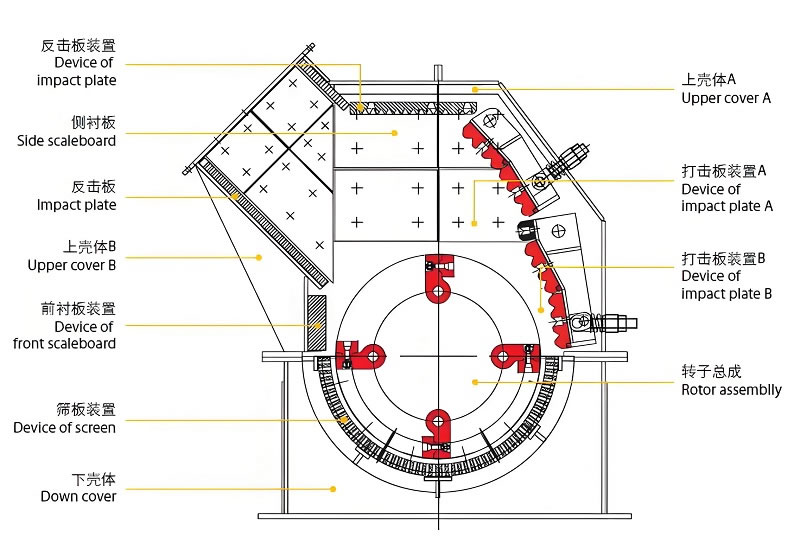

The working principle of vertical compound crusher is to use the material to be hit by the high-speed rotating hammer or plate hammer in the crushing chamber, and be forced to throw it to the counterattack plate, and gradually crush it after multiple impacts and friction. The crushed material is discharged through the screen plate to achieve the required particle size requirements. The equipment adopts a screen-free design and adjustable fine crushing, which can flexibly adjust the discharge particle size to meet different production needs.

3. Performance advantages of vertical compound crusher

Adjustable discharge particle size: The discharge particle size can be adjusted arbitrarily, and is not affected by the wear of plate hammers and liner plates. One machine can be used for multiple purposes to produce sand and gravel of various specifications.

Good material grade: The striking operation principle makes the material uniform, without excessive needle-like materials, and the sand material is cubic, uniform in particle size and high in quality.

Not easy to clog: No screen bar setting, it is not easy to clog when crushing materials with high moisture content and high mud content.

Wear-resistant and durable: The rotor body has a special structure, which has little wear when crushing materials and has a long service life.

Easy replacement of wearing parts: The rear cavity is equipped with a screw or hydraulic opening mechanism, and wearing parts can be easily replaced without starting the main equipment.

4. Application scope of vertical compound crusher

Vertical compound crusher is widely used in the fine crushing of raw materials and clinker in cement plants. It can also be used for the fine crushing of medium hardness materials such as dolomite, coke, lead-zinc ore, serpentine, blast furnace slag, coal gangue, phosphate rock, etc. It is especially suitable for the processing and crushing of artificial sand or highway pavement stones such as hard limestone, dolomite, granite, basalt, etc.

PS: The vertical compound crusher adopts a screen-free design, adjustable fine crushing, uniform product particle size, high bulk density, minimal iron pollution, low working noise, and less dust pollution. It is one of the indispensable crushing equipment in modern industry. Vertical compound crusher is an efficient and multifunctional crushing equipment with a wide range of applications and significant performance advantages.

The composite crushing hammer and rotor are rigidly connected, and the inertia of the whole rotor is used to impact material, which can obtain greater speed and kinetic energy, making it easier to crush and lower energy consumption.

The structure of the crushing cavity is designed to be large, so that the material has a certain space for movement in it. The material is impacted and can be fully broken after repeated blows.

The impact crushing steel disc structure and the hammer disc are staggered. This kind of new design enhances the working performance of the crusher effectively .

The combined structure of hammer head make it easy to replace severely worn parts only. It greatly improves the service life of the hammer head, and effectively reduces the production cost and the replacement frequency of the wearing parts of the equipment.

Different materials have different hardness, and materials with excessively high hardness may require more durable crusher components. The size of the feed inlet needs to be able to accommodate the largest block of material to be crushed, and some materials may cause blockage problems if they contain high moisture or viscosity.

The maximum feed size that the equipment can accept, adjust the discharge particle size of the crusher according to the needs of the final product, and determine the amount of material that the crusher can process per unit time to ensure that it can meet your production needs. The motor power will affect energy consumption and operating costs.

Large crushing ratio, discharging particle size can be adjusted arbitrarily, not affected by wear of hammer and liner plate.

Without screen bar, it is not easy to block when crushing materials with high moisture content and mud content.Good sealing and dust removal device eliminate dust pollution to meet environmental standards.

The unbreakable material can be discharged automatically due to elastic adjustment mechanism and crusher machine will not be damaged.

The composite crusher has high production efficiency, unique structure, smooth operation, low noise, and easy maintenance. It can easily replace damaged parts by opening the working compartment door.

The material is added from the upper mouth and falls into the crushing chamber. It is hit by a high-speed rotating plate hammer and quickly thrown towards the counterattack plate. After the impact, it is bounced back onto the hammer plate and hit again. Such high-frequency strikes and counterattacks gradually break the material from large to small, with smaller materials falling into the lower crushing chamber and being hit by high-speed rotating dense hammer heads, repeating the upper crushing process. Due to the small size of the cavity, shear stress is applied between the hammer head and the teeth of the impact plate to some materials for milling, accelerating the fine crushing of the materials. At the same time, the hammerhead produces a flow of animal material, which creates a significant grinding effect between them, causing the material to be further finely crushed until it is broken into the required particle size.

| Model | Feeding Size(mm) | Output Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension (L*W*H) |

| ZVCC-800 | < 50 | < 3-5 | 10-20 | 22-37 | 2100*1200*1700 |

| ZVCC-1000 | < 80 | 20-40 | 45-75 | 2600*1400*1900 | |

| ZVCC-1250 | < 150 | 40-70 | 75-132 | 2800*1600*2100 | |

| ZVCC-1500 | < 180 | 70-100 | 132-200 | 3100*1900*2200 | |

| ZVCC-1750 | < 200 | 130-190 | 200-315 | 3710*2360*2390 | |

| ZVCC-2000 | < 220 | 200-260 | 315-355 | 4100*2660*2620 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.