The LSY series shaftless screw conveyor is a device that transports materials without a central shaft relying on the rotation of the screw body. It can not only transport light, soft, small, and banded floating materials, but also separate solid and water, and press dirt. It is suitable for continuous and uniform transportation of loose, sticky, and easily entangled materials.

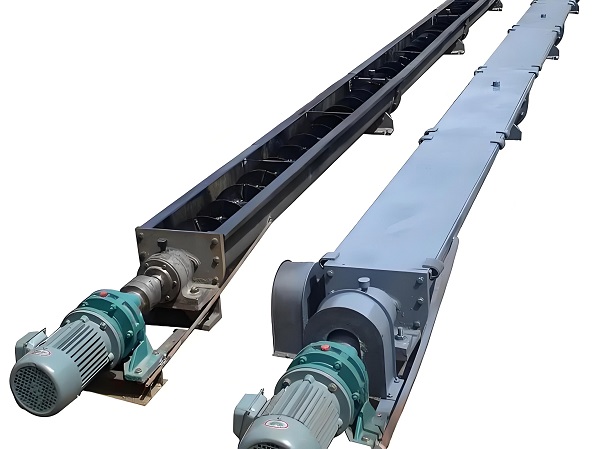

The shaftless screw conveyor is composed of the shell, screw blades, material inlet and outlet, and driving device. It is a widely used conveying equipment in the mining, food, chemical, construction, and solid waste recycling industries.

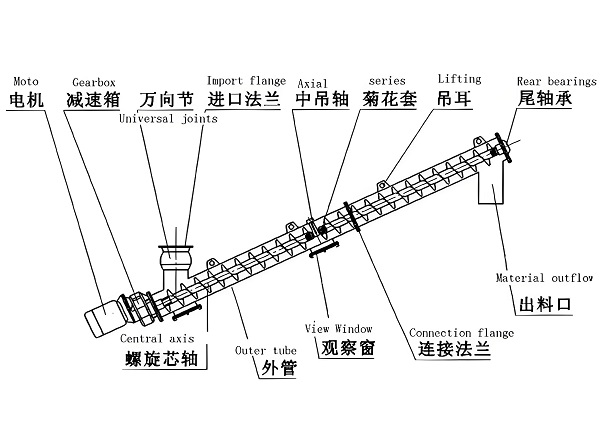

The shaftless screw conveyor is driven by the electric motor to operate a cycloidal reducer, relying on the mechanical seal shaft and the connecting plate on the shaftless screw body to drive and rotate the screw. After the material is discharged to the feeding inlet, the sludge is discharged from the material outlet through a screw drive.

1.Screw conveyors can be divided into shaft screw conveyors and shaftless screw conveyors in terms of conveying form, and can be divided into U-shaped screw conveyors and tubular screw conveyors in terms of appearance. Shaft screw conveyors are suitable for non-viscous dry powder materials and small particle materials, while shaftless screw conveyors are suitable for conveying viscous and easily entangled materials.

2. Screw conveyors can realize sealed transportation, which is conducive to the transportation of materials that are easy to fly, hot and smelly, and can reduce environmental pollution.

3. Screw conveyors can be conveyed in reverse, and a conveyor can also convey materials in two directions at the same time, that is, to the center or away from the center.

It can operate at lower speeds, with low energy consumption, high torque, and smooth transmission.

The use of fully enclosed conveying and easy to clean screw surfaces can protect environmental hygiene, and the transported materials are not contaminated or leaked.

No central shaft interference, strong anti-winding ability, and special advantages for conveying banded and easily entangled materials to prevent accidents caused by blockage.

The screw is wear-resistant and durable, with a long service life.

By adopting sliding bearing, dustproof sealed device and slide block, that make screw conveyor easy to install and maintain. When the screw shaft rotates, rotary spiral vane pushes materials continuously moving forward in closed housing.

| Model | LSY165 | LSY219 | LSY273 | LSY325 | LSY425 |

|---|---|---|---|---|---|

| Diameter(mm) | 165 | 219 | 273 | 325 | 425 |

| Operation Angle | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 |

| Max length(mm) | 12 | 13 | 15 | 15 | 18 |

| Max capacity (ton) | 10 | 30 | 50 | 80 | 110 |

| Motor power(kw) | 2.2-15 | 2.2-22 | 3-22 | 5.5-22 | 5.5-22 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.