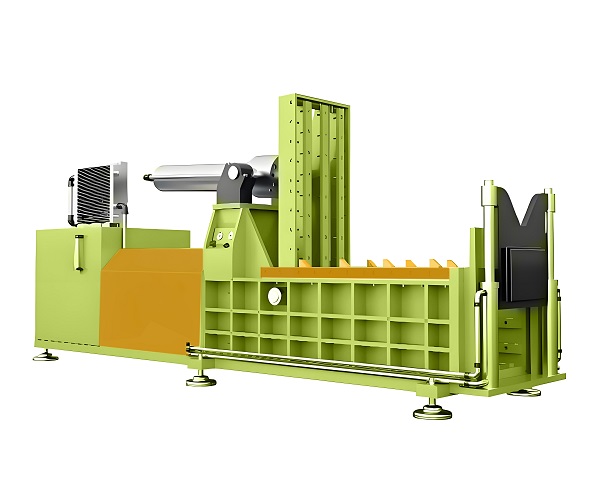

ZHP horizontal hydraulic baler is a kind of widely used equipment for baling loose materials such as waste paper, waste plastics, straw, and alternative fuel bulk materials. By using a hydraulic system, loose materials are efficiently compressed, greatly reducing volume, increasing density, lowering transportation costs, and facilitating centralized processing, transportation, and storage.

The horizontal hydraulic baler is a highly efficient and environmentally friendly piece of equipment that combines hydraulic technology with mechanical structure to horizontally compress and bundle various loose materials. It is widely used in resource recycling, agricultural and forestry processing, waste disposal, textiles, and chemicals, and is a core piece of equipment for promoting material volume reduction and resource recycling. Its horizontal structure design features a convenient and easily accessible feed inlet, and it can be paired with a conveyor belt for continuous feeding, significantly reducing manual labor intensity and making it suitable for large-volume material processing scenarios.

The core advantage of this equipment lies in the stable output of its hydraulic system, which mainly consists of an oil tank, hydraulic pump, hydraulic valves, and cylinders. It provides uniform high pressure, compressing lightweight materials such as waste paper, plastics, straw, textiles, wool, and medicinal herbs into uniformly dense and regularly shaped bales that meet relevant industry standards. This not only significantly reduces material volume and saves storage space but also lowers transportation costs, solving the pain point of inconvenient handling of loose materials. Some models can achieve one-time bale forming for silage and yellow silage straw, contributing to the resource utilization of agriculture and animal husbandry.

The equipment is easy to operate and safe and reliable. Most models are equipped with a PLC microcomputer control system, supporting both manual and automatic operation. It can automatically complete the entire process of feeding, compression, bundling, and bale output without much manual intervention. It also features multiple safety alarm devices that automatically shut down in case of misoperation or abnormal pressure, ensuring operational safety. The frame is welded from high-quality steel plates, offering strong pressure and tensile strength. Key components are made of high-quality parts, ensuring stable operation, low noise, high durability, and easy maintenance.

Whether it's a large-scale recycling station, a paper mill, an agricultural and forestry cooperative, or a textile factory, the horizontal hydraulic baler can meet all needs. Models can be customized according to material type and output, flexibly adjusting compression pressure and bale size. It not only improves material handling efficiency and reduces labor costs but also promotes the recycling and reuse of waste materials, reducing resource waste. Combining economic benefits and environmental value, it has become an essential piece of equipment for various industries to improve production efficiency and practice green development concepts.

When choosing a horizontal garbage compactor, multiple factors need to be considered to ensure that the selected equipment can meet actual needs and has good performance and durability. Here are some key selection points:

1. Choose the appropriate model of garbage baler based on the characteristics of garbage size, weight, shape, production requirements, etc. Select a packaging machine with sufficient processing capacity based on daily or hourly packaging requirements.

2. Consider machine performance: Choose a packaging machine with high automation and fast packaging speed to improve production efficiency and reduce labor costs. Ensure that the packaging machine can evenly and tightly pack items to reduce damage and looseness during transportation.

3. Quality of packaging machine: Choose packaging machines with excellent materials, exquisite craftsmanship, and strict testing to ensure their long-term stable operation.

4. Choose packaging machines from well-known brands, which usually have richer production experience, more complete product lines, and more reliable after-sales service.

5. Understand the brand's after-sales service policy, including warranty period, repair response speed, parts supply situation, etc., to ensure timely technical support and maintenance services during use.

Adopting ship classification welding technology to ensure more stable and reliable equipment.

Compact structure, small footprint, and convenient operation and maintenance.

Fully automatic compression and baling device, saving labor costs and improving work efficiency.

Adopting Europe imported sealing elements, the oil seal has good reliability and long service life.

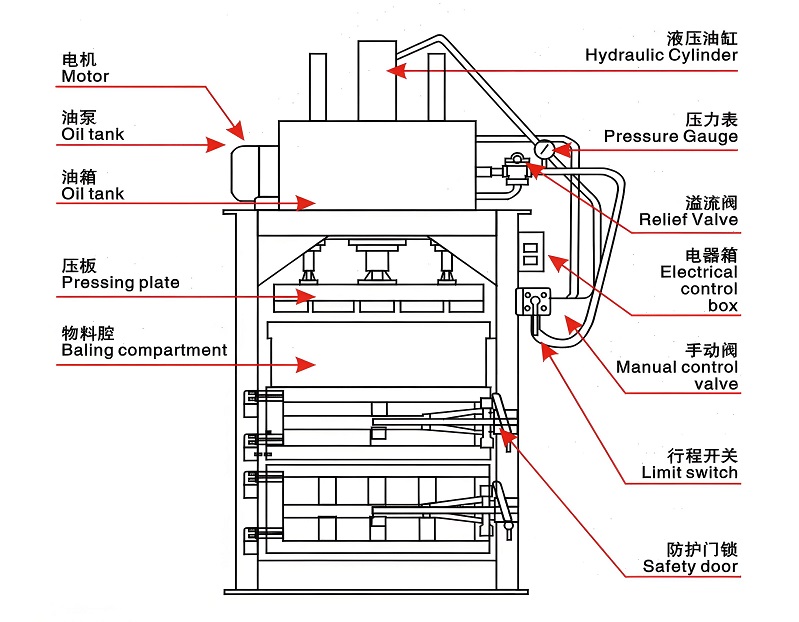

The working principle of Horizontal Hydraulic Baler mainly involves the synergistic effect of hydraulic system and mechanical structure. The following is a detailed explanation of its working principle:

1.Working principle of hydraulic system

Pressure generation: The horizontal hydraulic baler generates high-pressure liquid through a hydraulic pump, which is transported to the hydraulic cylinder.

Pressure transmission: The piston inside the hydraulic cylinder is subjected to the action of high-pressure liquid, thereby generating thrust or tension. This thrust or tension is transmitted to the compression components of the baler through the connecting rod or transmission mechanism of the hydraulic cylinder.

Pressure control: By using control components such as relief valves and pressure reducing valves in the hydraulic system, the working pressure of the hydraulic cylinder can be adjusted to achieve precise control of the compression force of the baler.

2.Working principle of mechanical structure

Material placement: Place the materials that need to be packaged (such as waste paper, cardboard boxes, plastics, etc.) into the hopper of the packaging machine.

Compression process: After starting the packaging machine, the hydraulic cylinder starts working, pushing the compression component to compress the material. During the compression process, the material is gradually compacted and forms lumps.

Block formation: When the block reaches the predetermined size and density, the hydraulic cylinder stops working. At this point, the packaging blocks have been tightly compressed together, facilitating subsequent transportation and storage.

Package block discharge: After the package block is formed, it is discharged from the machine through the packaging mechanism of the packaging machine. The delivery mechanism may include a package pushing device, conveyor belt, etc.

3.Automation and Control Systems

PLC control: Modern horizontal hydraulic balers usually use PLC (Programmable Logic Controller) for automation control. PLC can receive signals from sensors and accurately control and adjust the packaging machine according to preset programs.

Sensor monitoring: Sensors are used to monitor the working status of the packaging machine, such as material feeding amount, packaging block size, compression force, etc. These sensors transmit the monitored data to the PLC, which adjusts the working parameters of the packaging machine based on the data.

Fault alarm: If there is a fault or abnormal situation in the packaging machine during operation, the PLC will immediately trigger the alarm system to remind the operator to handle it.

4.Security protection measures

Emergency stop button: The packaging machine is usually equipped with an emergency stop button, which is used to immediately stop the operation of the machine in case of emergency.

Safety protection devices: The key parts of the packaging machine are usually equipped with safety protection devices, such as protective covers, safety doors, etc., to prevent operators from entering dangerous areas by mistake.

Overload protection: Hydraulic systems are usually equipped with overload protection devices to prevent hydraulic cylinders from being damaged in the event of overload.

In summary, the horizontal hydraulic baler achieves compression and packaging of materials through the synergistic effect of the hydraulic system and mechanical structure. At the same time, the application of automation and control systems, as well as security measures, ensures the efficient, safe, and stable operation of the packaging machine.

| Model | Capacity (t/h) | Power (kW) | Pressure (ton) |

| ZHP | 2-10 | 18.5-45 | 60-100 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.