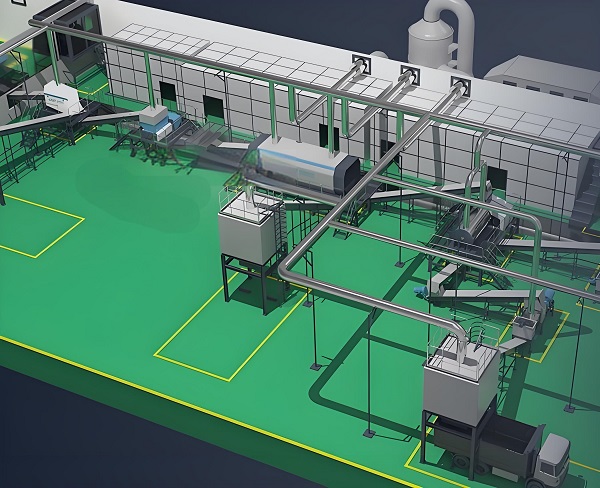

The kitchen waste resource utilization system of Zhongcheng Machinery can achieve efficient separation of inorganic and organic substances in kitchen waste. After crushing, sorting, and pressing, different substances are classified and processed into corresponding recyclable resources. The system operates automatically throughout the process, which can significantly save labor and improve waste treatment efficiency.

Kitchen waste accounts for about 50% -60% of domestic waste. It refers to the waste generated in the daily life of residents and activities such as food processing, catering services and unit catering, including discarded vegetable leaves, leftovers, leftovers, peels, eggshells, tea dregs, bones, etc. Its main sources are home kitchens, restaurants, restaurants, cafeterias, markets and other industries related to food processing.

Kitchen waste contains high levels of moisture and organic matter. After proper treatment and processing, kitchen waste can be transformed into new resources, which can be used as fertilizer, feed, biogas for fuel or power generation, and the oil and fat portion can be used to prepare biofuels.

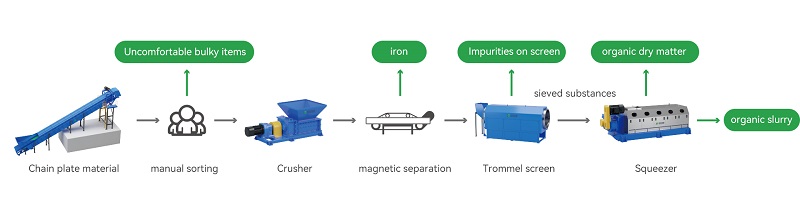

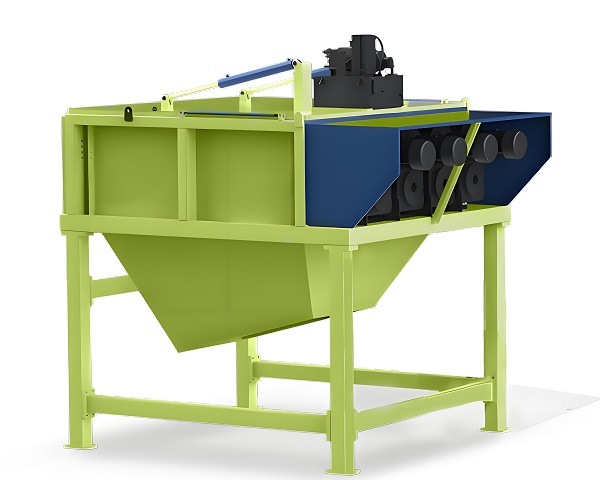

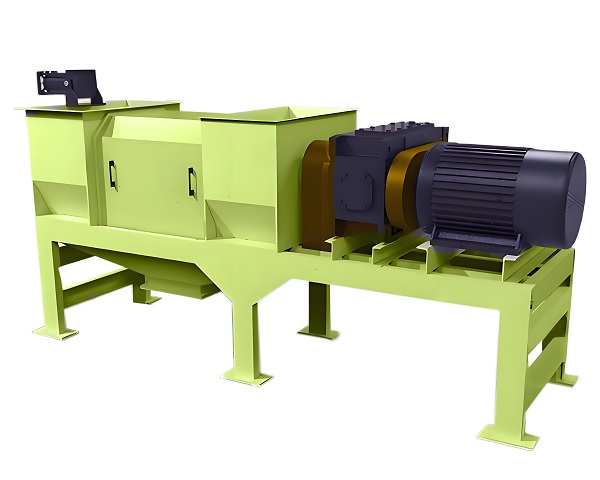

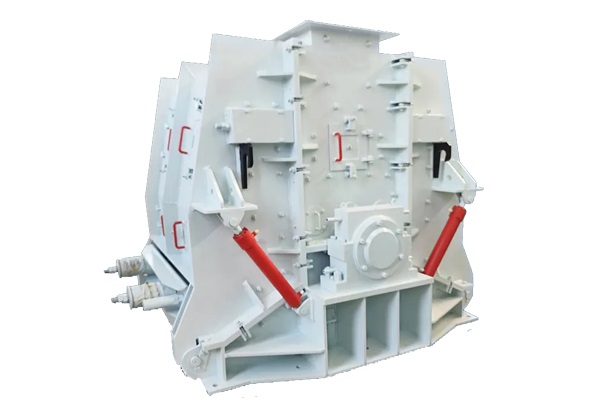

The kitchen waste resource utilization system of Zhongcheng Machinery adopts a process route of "feeding+coarse sorting+crushing+fine sorting+multi-stage spiral pressing", which can achieve fine separation and effective recovery of organic and inorganic matter. The resource utilization system has advanced technology, complete functions, strong processing capacity, high degree of automation, high resource utilization rate, and high customer satisfaction.

The kitchen waste resource utilization system designed by Zhongcheng Company uses systematic operations such as bag breaking, crushing, sorting, dehydration, and compression to remove flexible materials such as plastics and paper, as well as hard materials such as stones, glass, broken porcelain pieces, and metals, reducing the moisture content of solid slag and ultimately obtaining high-purity and high-value organic matter, thereby achieving the resource utilization, reduction, and harmless treatment of kitchen waste.

Advantages of the plan:

1. The plan can be flexibly adjusted according to the differences in the composition of kitchen waste in different regions, and the material adaptability is good;

2. All equipment is designed with targeted measures for corrosion resistance, wear resistance, impact resistance, waterproofing, and dust prevention. The production line can operate stably and continuously for a long time;

3. The entire disposal process is fully enclosed with good sealing, effectively preventing the leakage of odors and harmful substances;

4. Equipped with professional sewage treatment systems and dust removal and deodorization equipment to meet environmental protection requirements;

5. The intelligent system monitors various operational data of the production line in real time, timely understands the equipment operation status, and realizes intelligent, digital, and refined management of production line monitoring.

Craftsman's mind creates lean products

Save Time! Get A Detailed Quotation Quickly.