Optical sorters are automated sorting equipment based on optical principles. Their core components include a light source, optical sensors, an image processing system, and actuators. During operation, the light source illuminates the material, while the sensor captures its optical characteristics. The system rapidly analyzes and compares the material, identifying unqualified or specific types of material. These are then precisely separated using actuators (such as air jet valves).

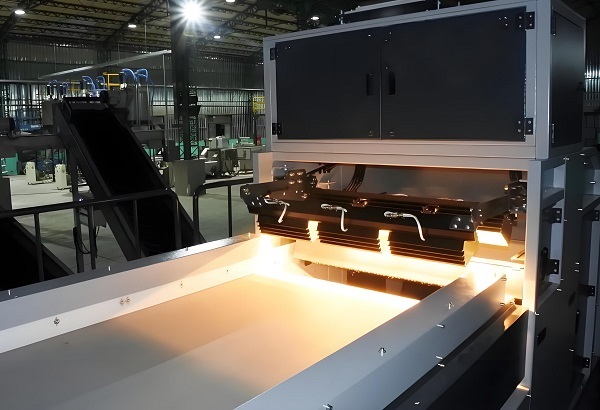

Optical sorters are core automated sorting equipment in modern industry. Relying on optical inspection technology to achieve precise material sorting, they are widely used in production processes across multiple sectors. Their core system consists of a high-brightness, stable light source (such as LED or laser), a high-resolution optical sensor (such as a CCD camera or spectrometer), a high-speed image processing unit, and precise actuators (such as air valves and actuators), forming a complete closed-loop process of "illumination - capture - analysis - separation."

During operation, materials pass through the inspection area at a constant speed. Under the illumination of the light source, the sensor captures the material's optical characteristics in real time, including color differences, shape and contour, internal defects (such as mineral impurities and food mold), and component spectra. The image processing system compares the material to preset standards at millisecond speeds, identifying defective or target materials. The actuator then precisely operates to achieve efficient material separation.

In the mining industry, these devices can be used to sort different grades of ore; in the food industry, they can remove rotten fruits and vegetables and moldy nuts; and in recycling, they can separate different plastic and paper materials. Compared with manual sorting, the sorting efficiency of optical sorting machines is increased by 5-10 times, with an accuracy of more than 99%. It not only reduces labor costs, but also ensures product quality stability, helping enterprises achieve large-scale and intelligent production upgrades.

Matching Material Characteristics: Select a machine model based on the material's form (granular, lumpy, flake), size range, and optical differences (color contrast, light transmittance). For example, sorting small nuts requires a high-resolution sensor, while sorting ores requires heavy-duty equipment that is dust-resistant.

Focus on Core Configurations: Prioritize the light source type (LEDs offer greater stability, while lasers are suitable for high-precision component detection), sensor resolution (the higher the pixel count of a CCD camera, the more precise the detail capture), and image processing unit speed to ensure that the required sorting accuracy is met.

Verifying Sorting Performance: Request the manufacturer to provide actual material testing, focusing on sorting efficiency (volume per unit time) and accuracy (qualified product detection rate, impurity rejection rate). These should be aligned with your production capacity and quality standards.

Adapting to Production Scenarios: Consider the production environment (high temperature, humidity, and dust concentration) and select equipment with the appropriate protection level (e.g., IP65 for dust and water resistance). Also, confirm that the equipment's dimensions fit within the existing production line layout to avoid space issues. Examine the actuator: Choose the actuator type based on the material weight. For light materials (such as plastic pellets), choose an air-jet valve (fast response), while for heavy materials (such as ore), choose a push-rod mechanism (strong stability) to ensure precise and smooth separation.

Emphasis on after-sales service and maintenance: Choose a brand with a comprehensive after-sales service. Verify whether they offer services such as installation and commissioning, operator training, and replacement of consumable parts (such as light sources and nozzles). Also, understand the equipment's mean time between failures (MTBF) to reduce future maintenance costs.

Compare cost and performance: In addition to the equipment's purchase price, consider long-term costs (energy consumption, consumables replacement, and maintenance). Avoid simply pursuing a low price while ignoring stability and adaptability. Prioritize cost-effective models that meet performance standards and have manageable maintenance costs.

The use of high-resolution sensors and self-developed image processing systems can accurately identify subtle defects, significantly reducing the rate of defective products; eliminating manual sorting errors and ensuring consistent quality.

Supports multi-dimensional customization: sorting channels and actuators can be adjusted according to material size and shape; sensor parameters can be customized according to sorting accuracy requirements; equipment size can also be adjusted to adapt to production line layout, and equipped with exclusive image processing algorithms to accurately match the production needs of different industries.

Our company's optical sorting machines offer exceptional high performance: equipped with high-speed image processing chips and highly sensitive sensors, they respond to sorting requests in milliseconds. They offer a sorting efficiency of several tons per hour and an accuracy exceeding 99%. Furthermore, they can stably cope with dusty and temperature-differential environments, operate continuously without failure, and are suitable for high-intensity production needs.

Optical sorting machines rely on optical technology for automated sorting, with efficient sorting and a processing capacity far exceeding that of manual labor. They have high precision and can accurately identify subtle differences in materials. They are highly adaptable and can match materials of different shapes and types and complex production environments. They have good stability, reduce human errors, and can also lower manpower and operation and maintenance costs, contributing to intelligent production.

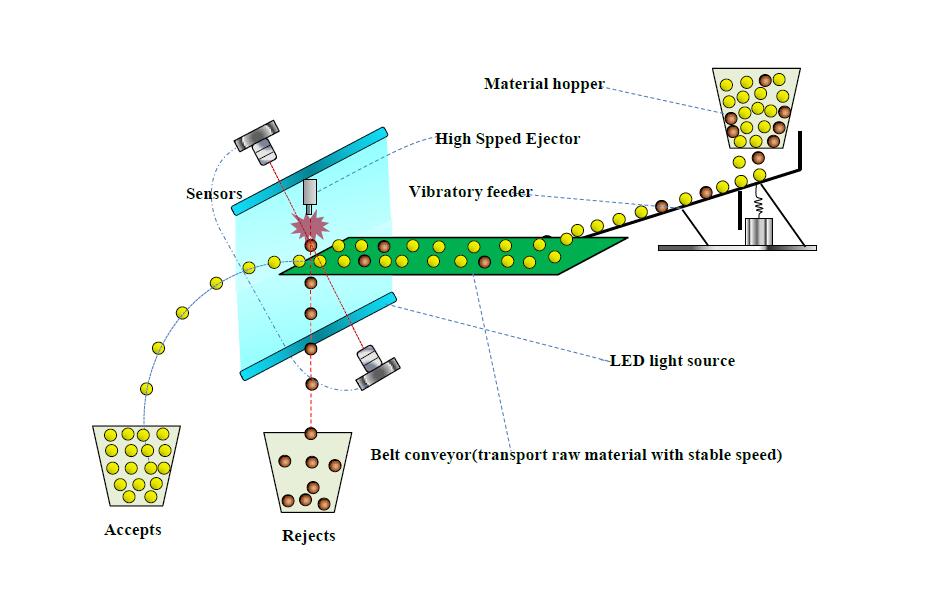

Optical sorters, with optical inspection at their core, achieve automated material sorting through a four-step process: conveying - inspection - analysis - sorting. The detailed principles are as follows:

First, materials are transported to the inspection area at a constant speed via a vibrating feeder or conveyor belt, ensuring even distribution and no accumulation, laying the foundation for accurate inspection. Subsequently, a high-stability light source (such as an LED or laser) illuminates the material, fully revealing its surface or internal optical properties (color, shape, transmittance, and spectral information).

Next, a high-resolution optical sensor (such as a CCD camera or spectrometer) captures the material's optical signals in real time, converting them into electrical signals for transmission to a high-speed image processing unit. This unit analyzes and compares the signals within milliseconds based on pre-set sorting criteria (such as color thresholds for qualified materials and defect characteristics), rapidly identifying qualified and unqualified products (or target materials and impurities). Finally, the image processing unit sends instructions to the actuators (such as air jet valves and push rods). When the materials to be sorted reach the specified position, the actuators move precisely. Light materials are often separated by instantaneous air jets using air jet valves, while heavy materials are pushed through using push rods. Ultimately, different types of materials are efficiently diverted and the entire sorting process is completed.

| Model | Sorting Width (mm) | Capacity (t/h) | Detection Technology | Resolution (mm) | Air Jet Nozzles | Power (kW) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|---|---|

| OSM-600 | 600 | 1–2.5 | RGB + NIR | 0.2 | 64 | 1.5 | 1800×1000×1600 |

| OSM-900 | 900 | 2–4 | RGB + NIR + AI | 0.2 | 96 | 2.2 | 2000×1300×1700 |

| OSM-1200 | 1200 | 3–6 | RGB + SWIR | 0.2 | 128 | 3.0 | 2200×1500×1800 |

| OSM-1600 | 1600 | 4–8 | Multispectral + AI | 0.2 | 160 | 4.0 | 2400×1800×1900 |

| OSM-1800 | 1800 | 5–10 | Full-Spectrum + AI | 0.2 | 192 | 4.5 | 2600×1900×2000 |

| OSM-2100 | 2100 | 6–12 | Multisensor Fusion | 0.2 | 224 | 5.5 | 2800×2000×2100 |

| OSM-2400 | 2400 | 7–14 | RGB + NIR + X-Ray | 0.2 | 256 | 6.5 | 3000×2200×2200 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.