The single-cylinder cone crusher is a high-efficiency crushing equipment that combines advanced design concepts. It has the characteristics of high efficiency, large production capacity, high-quality stone, and easy maintenance. It is widely used in medium, fine and ultra-fine crushing operations in metal and non-metallic minerals, cement, sandstone, metallurgy and other industries, especially for hard rock crushing. The single-cylinder cone crusher has been widely used in the field of mining crushing due to its simple structure, stable performance, large crushing ratio and high production efficiency.

The single-cylinder cone crusher is an efficient and energy-saving crushing equipment, which is widely used in mining, metallurgy, building materials, chemical industry and other industries. The following is a detailed introduction to the single-cylinder cone crusher:

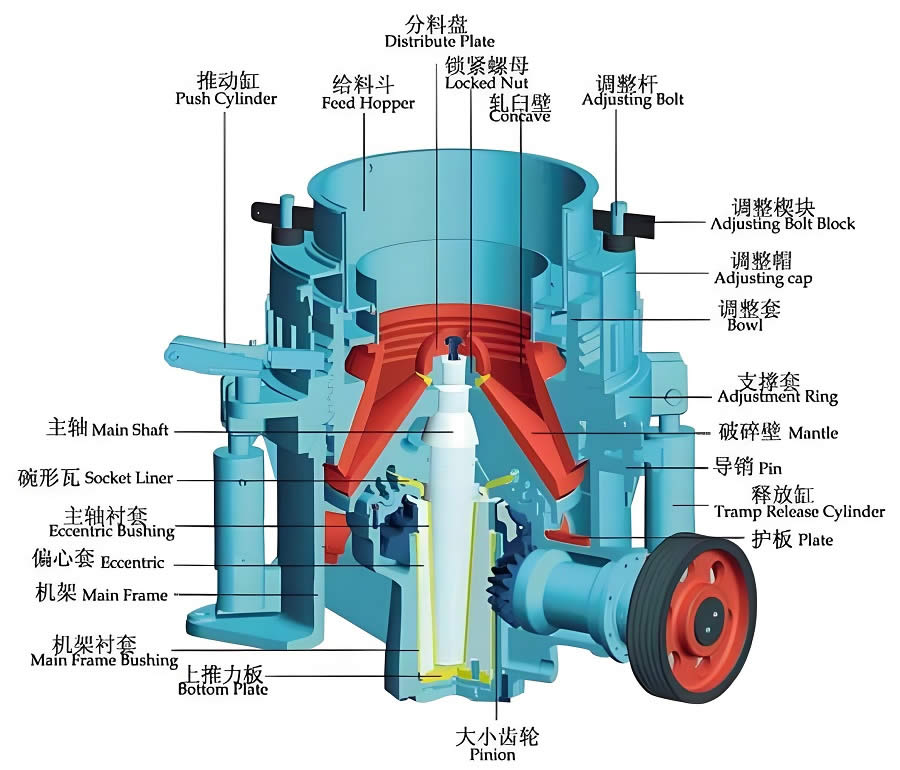

The working principle of the single-cylinder cone crusher is to drive the eccentric sleeve to rotate through the motor to make the moving cone do a swinging motion. When the moving cone is close to the fixed cone, the material is crushed by extrusion, bending and shearing; when the moving cone leaves the fixed cone, the crushed material is discharged from the discharge port. By adjusting the size of the discharge port, the particle size of the product can be controlled.

1. Structural features of the single-cylinder cone crusher

Single-cylinder structure: The single-cylinder cone crusher adopts a single-cylinder hydraulic structure, which simplifies the structure of the crusher and reduces maintenance costs.

High-performance crushing chamber: The crushing chamber is reasonably designed, which improves the crushing efficiency and reduces energy consumption.

Hydraulic adjustment and protection: The size of the discharge port can be easily adjusted through the hydraulic system, and overload protection can be achieved at the same time to avoid equipment damage.

Automatic control: Equipped with an advanced automatic control system, remote monitoring and operation can be achieved to improve production efficiency.

2. Application advantages of single-cylinder cone crusher

High efficiency and energy saving: Single-cylinder cone crusher has the characteristics of high efficiency crushing and low energy consumption, which improves production efficiency.

Uniform particle size of finished products: By adjusting the size of the discharge port, a finished product with uniform particle size can be obtained to meet user needs.

Easy maintenance: Simple structure, easy maintenance and overhaul, reducing downtime.

PS: Single-cylinder cone crusher has a wide range of application prospects in the field of mining crushing with its advantages of high efficiency, energy saving, and uniform particle size of finished products.

1. The upper and lower ends of DG cone crusher main shaft are supported. It can withstand greater crushing force and greater stroke, so that the machine has higher crushing efficiency.

2. The main shaft of the single-cylinder cone crusher is installed on the bottom hydraulic cylinder, and the bottom hydraulic cylinder can be adjusted up and down to change the size of the discharge port.. This makes the adjustment convenient.

3. The joint surface between the rolling mortar wall and the cone is stable and firm. It could be quick replacement of vulnerable parts without more filling supplements. The replacement time of wearing parts is saved.

4. Double safety control hydraulic and lubrication system can ensure overload protection of the machine and good bearing lubrication.

5.In addition to the price of the equipment itself, the operating and maintenance costs of the equipment also need to be considered. Choosing equipment with low energy consumption and easy maintenance can reduce overall operating costs.

When choosing a single cylinder cone crusher, multiple factors need to be considered, including usage and material characteristics, production capacity and specifications, performance characteristics, reliability and durability, price, and cost-effectiveness. By comprehensively evaluating and comparing different brands and models of equipment, one can choose the most suitable single cylinder cone crusher for their production needs.

Feeding hooper with high efficient rotation speed makes the wear of the liner plates even and uniform.

Parts adopt high quality steel,reliable performance and operation more safety.Simple structure and wearing parts can be changed or repaired easily.

Automatic overload protection to avoid stoppig due to entering of iron lock.

Good product particle size, strong production capacity, optimized structure, strong load-bearing capacity, optional crushing chamber, high crushing efficiency.

When the single cylinder hydraulic cone crusher is working, the motor drives the small gear of the crusher, and the small gear drives the large gear. The large gear component drives the eccentric sleeve component and the main shaft component to revolve around the copper sleeve in a theoretical vertical line, and the main shaft component can rotate on its own within the eccentric copper sleeve. When the machine is running empty, the eccentric sleeve component "holds" the main shaft component and revolves together with the large gear. When the material is added to the crushing chamber, the main shaft assembly (main shaft, inner cone) slowly rotates inside the eccentric copper sleeve under the resistance of the material. The trajectory of the inner cone appears to oscillate back and forth within the crushing chamber, while slowly rotating. The material is crushed by the swinging inner cone. The connection between the support sleeve and the frame is compressed by a hydraulic cylinder. When metal blocks or other unbreakable objects fall into the crusher, the moving cone of the single cylinder is supported by the bottom hydraulic piston, which plays a role in adjusting the discharge port, protecting against iron overload, and repeatedly lifting and lowering to remove blockages.

| Model | Cavities | Feeding Size (mm) | Adjusting Range of Discharge Opening (mm) | Capacity (t/h) | Power (kw) |

| ZSC100 | Coarse | 150 | 16-40 | 60-125 | 90 |

| Medium | 100 | 14-35 | 50-100 | ||

| Fine | 50 | 10-30 | 40-100 | ||

| ZSC200 | Coarse | 180 | 16-50 | 120-230 | 160 |

| Medium | 140 | 14-40 | 100-210 | ||

| Fine | 70 | 10-30 | 80-180 | ||

| ZSC300 | Coarse | 200 | 20-60 | 200-400 | 250 |

| Medium | 140 | 16-45 | 160-350 | ||

| Fine | 90 | 12-35 | 130-280 | ||

| ZSC400 | Coarse | 230 | 20-65 | 260-500 | 315 |

| Medium | 160 | 16-50 | 200-400 | ||

| Fine | 100 | 12-40 | 160-350 | ||

| DG500 | Coarse | 250 | 20-75 | 350-650 | 355 |

| Medium | 170 | 16-50 | 280-500 | ||

| Fine | 100 | 12-40 | 200-450 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.