Mobile concrete crusher, also known as construction waste mobile crusher, is an efficient concrete rock crushing equipment, which is suitable for processing construction waste such as concrete aggregate. Movable concrete crusher is widely used in construction waste reprocessing and processing industries due to its strong crushing capacity, flexible mobility and high efficiency in energy conservation, and it is an important equipment for concrete solid waste treatment.

Movable concrete crusher is a kind of crushing equipment specially designed for processing construction waste such as concrete aggregate, which is widely used in construction waste reprocessing and processing industries. The following is a brief introduction to the equipment:

The equipment has a strong crushing capacity, with a processing capacity of 10-650t/h in general, and can fine and medium crush various materials with a compressive strength of less than 250Mpa. The depth of the crushing chamber is large and there is no dead zone, which greatly improves the feeding capacity and discharging capacity. The product has uniform particle size and beautiful particle size, meeting various application standards.

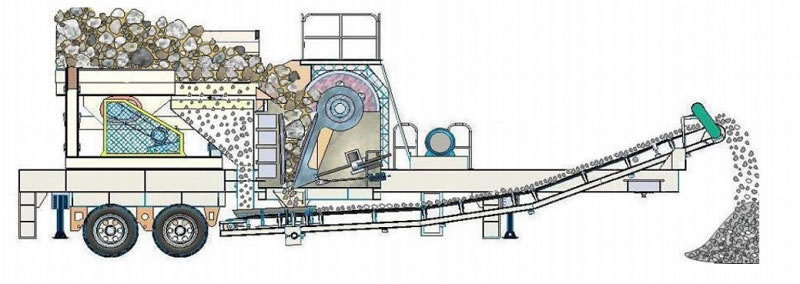

The mobile concrete crusher adopts tire or crawler carrier, with compact and reasonable structure and excellent moving performance. This enables the equipment to be quickly deployed at different operation sites, with low requirements for road transportation conditions, and extremely convenient and fast access to the site, greatly saving transportation costs. At the same time, the equipment can be configured with different types of crushers according to customer requirements to process materials of different specifications to meet various application requirements.

In terms of intelligence, mobile concrete crusher is equipped with advanced control system, which can realize remote control and intelligent central control. The design of PLC+touch screen makes the operation easier and safer and greatly improves the operation efficiency. In addition, the equipment has excellent environmental protection performance, which can effectively reduce dust pollution in the operation process and meet the environmental protection requirements of the current aggregate production.

PS: The mobile concrete crusher plays an important role in the field of construction waste reprocessing and treatment by virtue of its strong crushing capacity, flexible movement performance, high efficiency energy conservation performance and excellent environmental protection performance.

When choosing a mobile concrete crusher, it is necessary to consider production needs, equipment configuration, investment budget, equipment performance, manufacturer's brand reputation, and other aspects to ensure that the selected equipment can meet your specific needs. The following are the key factors to consider when choosing a mobile concrete crusher:

1.Understand the hardness, size, moisture content, and other characteristics of the concrete waste you will be processing in order to select the most suitable crusher type.

2.Choose the appropriate type, the tire type is suitable for relatively flat ground, requires semi-trailer towing and movement, and is suitable for relatively flat areas such as highways. Crawler type has better maneuverability and adaptability, suitable for mountainous areas or harsher working environments.

3. Metal materials such as spare parts can be reprocessed and processed into stainless steel plates of specifications after sorting, centralization, and re-refining by express delivery.Waste bamboo and wood can be used to produce synthetic wood.

4. Waste such as bricks, stones, and concrete After crushing, it can replace sand and be used as masonry mortar, plastering mortar, foundation cushion, etc., and can be used to make decorative building materials such as aerated blocks, paving bricks, and lattice partition bricks.

5.Choose different types of crushers as needed, such as jaw crushers, impact crushers, etc.

The host is equipped with a steel bar cutting device to prevent blockage of the crusher. It is made of all steel material and of high quality. The chassis adopts a all steel ship structure with high strength, strong adaptability to the work site, and stable operation

The structural design is reasonable, the performance is excellent, the overall design is scientific and reasonable, and the comprehensive performance is further optimized. With excellent quality, its performance can be fully utilized

High power, safe and reliable, using a high-power walking motor with strong horsepower, safe and reliable production operation, simple operation and maintenance, low noise, energy-saving and environmentally friendly, using high-quality motors to achieve strong power system performance, with significant characteristics such as low noise and energy saving

Low operating costs, high work efficiency, simple operation, leading the industry, easy to use and maintain equipment, simple structure, high crushing ratio, wear-resistant, pressure resistant, and long service life

Concrete is uniformly transported by a bucket elevator through a feeder to a mobile concrete crusher. After being preliminarily crushed by the crusher, a closed-loop system is formed by a circular vibrating screen to achieve the cyclic crushing of concrete materials. Concrete that meets the particle size requirements is output by the conveyor to achieve production goals. According to actual production needs, the circular vibrating screen can be removed and the concrete can be initially crushed, and then combined with other crushing equipment for specific operations to obtain the required product.

The raw materials are sent into the material bin through equipment such as forklifts and excavators. The materials in the bin enter the screening feeder, and the part of the raw materials with the required particle size leaks out from the sieve holes and is directly formed into a soil pile through the excavation belt conveyor; Larger materials are fed into the impact crusher through a screening feeder for crushing, and then discharged from the discharge port into the vibrating unloader when the particle size meets the standard; The unloading machine evenly feeds the material into the main unloading belt conveyor, which transports the material out to form a pile; At the same time, a iron remover is installed above the main discharge belt, and the iron in the material is separated after being sucked in by the iron remover.

| Model | Vibrating feeder | Jaw crusher | Vibrating screen | Belt conveyor | Capacity | Power system | Chasis |

| ZCMC46-1548 | ZCVF850X3000 | PE400X600 | 3YK1548 | B650x10 X 3sets | 15-60 TPH | Electrical Control or Generator Set according to Jobsite | Tracked mobile,wheel mobile type,or skid frame |

| ZCMC57-1848 | ZCVF960X3800 | PE500x750 | 4YK1848 | B650x10 X 4sets | 50-100 tph |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.