The recovery rate of domestic waste after crushing and sorting is high, and the calorific value of plastic, foam, film and other materials is higher than that of steam coal. Mixing and processing into alternative fuels will help power plants save energy and reduce emissions. The resource utilization treatment process for household waste designed by Jiepu Intelligent Environmental Protection can be flexibly adjusted and configured according to different types of household waste to meet the needs of different projects.

Household waste refers to solid waste generated by people in their daily lives or activities that provide services for daily life, as well as solid waste that is considered household waste according to laws and administrative regulations, including unused cardboard boxes, cans, plastic bags, glass bottles, clothing, broken ceramics, and so on.

Household waste contains a large amount of recyclable materials, such as high calorific value combustibles that can be converted into alternative fuels (RDF, SRF) to reduce coal consumption, organic matter that can be composted or used for biogas digester fermentation, and high-value recyclable materials such as plastics, glass, metals, and waste paper that can be directly refurbished or processed as raw materials.

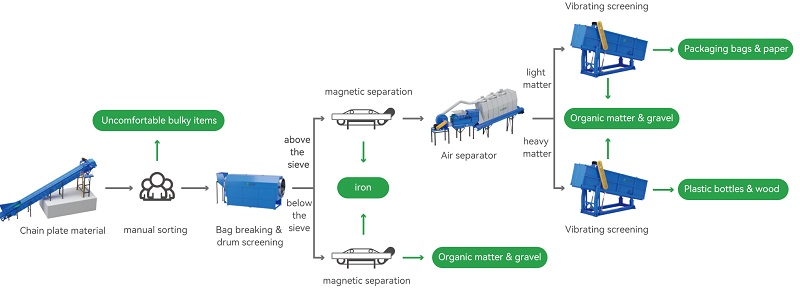

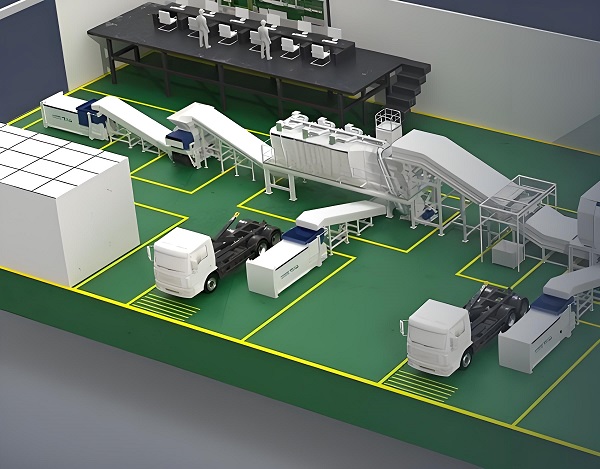

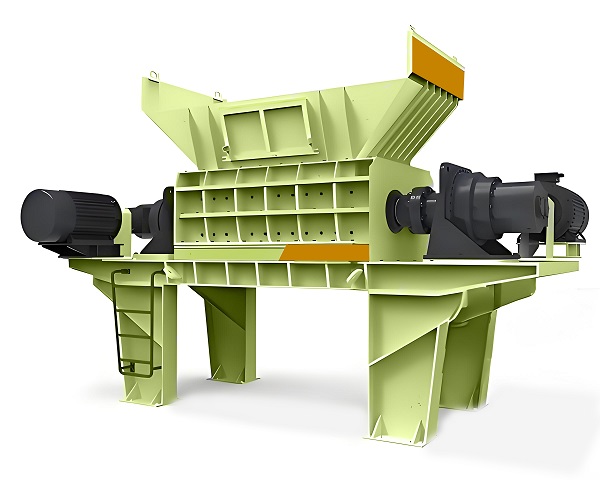

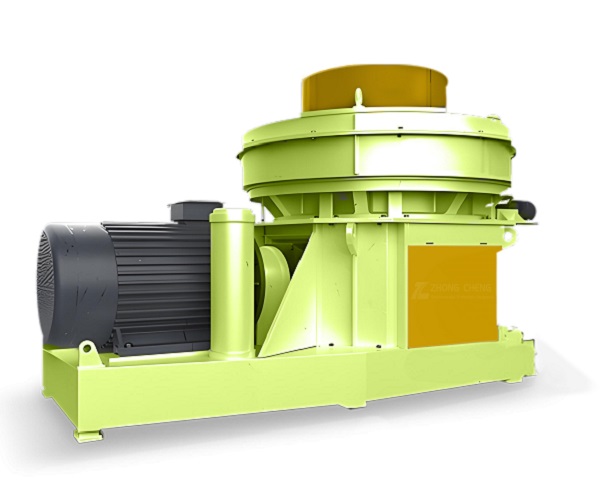

At present, the common methods for treating household waste include landfilling, composting, and incineration, but all of them must be crushed and refined before treatment. Zhongcheng Machinery has launched a practical, feasible, and economically reasonable system for the resource utilization of household waste in the market. The system equipment consists of a dual axis shredder, a fine crusher, a drum screen, a magnetic separator, an air separator, a conveyor, and a GI intelligent control system. The system has a high degree of automation, low energy consumption, and can also expand equipment such as drying, pressing and dehydration, packaging, and making RDF fuel rods according to specific processing needs, helping to achieve resource utilization of household waste.

Raw household waste is transported by a conveyor into a double shaft shredder for crushing or bag breaking, and then enters a drum screen for screening to remove non combustible inorganic substances such as slag. The screened material is then separated by a magnetic separator for iron removal and an air separator for combustible light substances. The undersized material screened by the drum screen, along with the heavy material sorted by the air separator, is used for engineering backfilling or greening base soil. And the combustible light substances are further transported to the fine crusher for secondary crushing, finally obtaining alternative fuels that meet the requirements of power plants, cement plants, paper mills, etc. According to processing needs, an RDF forming machine can be added to further grind and compress the material into RDF fuel rods, thereby increasing the calorific value per unit volume. (For detailed physical images, please refer to the case studies below or consult us)

Advantages of the plan:

1. The entire system has a high degree of intelligence, is safe, energy-saving, easy to operate, and has high processing efficiency, which can significantly save manpower and operating costs;

2. The system operates in a sealed manner and is equipped with environmental protection equipment such as dust removal and odor removal. The production process is clean and hygienic, with no secondary pollution;

3. The scope of garbage disposal is wide, and equipment parameters can be adjusted according to actual needs to meet more processing requirements.

Craftsman's mind creates lean products

Save Time! Get A Detailed Quotation Quickly.