Reversible hammer crusher is the main equipment for crushing concrete, finely crushed limestone, coal or other brittle materials with medium hardness or below in industrial sectors such as environmental protection, metallurgy, building materials, chemical industry and hydropower. Reversible hammer crusher is an efficient and reliable crushing equipment, which is widely used in various industrial fields and provides strong support for material fine crushing operations.

Reversible hammer crusher is a kind of efficient and multifunctional crushing equipment, which is widely used in many industrial fields such as mining, metallurgy, building materials, chemical industry, hydropower, etc. The following is a detailed introduction of reversible hammer crusher:

The working principle of reversible hammer crusher is to impact, shear and grind the material through the high-speed rotating hammer head to achieve the purpose of crushing. After the material enters the crushing chamber, it is hit by the hammer head and crushed. At the same time, the crushed material repeatedly hits between the hammer head and the impact plate to further crush it. Finally, the material smaller than the discharge port size is discharged from the lower part of the crusher to complete the crushing process.

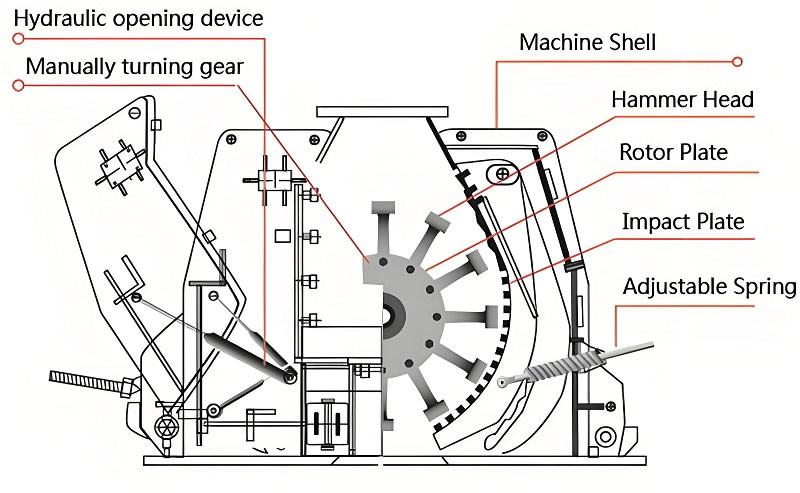

Reversible hammer crusher has the characteristics of large crushing ratio, high production capacity and uniform product particle size. Its main components include frame, rotor, screen bar, impact plate and adjustment device. During operation, the material enters the crusher and is crushed by the impact of the high-speed rotating hammer. Then, it obtains kinetic energy from the hammer and rushes to the baffle and screen bar in the frame at high speed. The materials collide with each other and are crushed many times. The materials smaller than the gap between the screen bars are discharged from the gap. The finely crushed materials are the required products.

Structural features of reversible hammer crusher:

1. Frame: welded with high-strength steel plates, with sufficient strength and rigidity to ensure stable operation of the equipment.

2. Rotor: equipped with multiple hammers, which are made of wear-resistant alloy materials with high hardness and wear resistance.

3. Screen bar: used to control the particle size of the crushed product, which can be adjusted according to user needs.

4. Impact plate: works with the hammer to repeatedly impact the material to improve the crushing efficiency.

5. Adjustment device: used to adjust the size of the discharge port to control the particle size of the crushed product.

Performance advantages of reversible hammer crusher:

1. High crushing efficiency: Due to the high-speed rotation of the hammer and the cooperation of the impact plate, the crushing efficiency is significantly improved.

2. Uniform product size: By adjusting the screen bars and the size of the discharge port, a crushed product with uniform particle size that meets user needs can be obtained.

2. Strong adaptability: The reversible hammer crusher is suitable for a variety of materials, such as limestone, coal, gypsum, etc., and has strong adaptability.

3. Smooth operation: The equipment uses high-strength materials and advanced manufacturing processes to ensure smooth operation and low noise.

Reversible hammer crushers are widely used in fine crushing operations in mining, metallurgy, building materials, chemicals, hydropower and other fields, such as crushing limestone, coal, gypsum, ore and other materials.

PS: Reversible hammer crusher is an efficient and reliable crushing equipment, widely used in various industrial fields, and provides strong support for material fine crushing operations. Reversible hammer crusher has the advantages of high crushing efficiency, uniform product particle size, strong adaptability and smooth operation. It is one of the indispensable crushing equipment in the industrial field.

When choosing a reversible hammer crusher, you need to consider several factors to ensure that you choose the equipment that suits your production needs. Here are some key selection factors:

1 Consider material characteristics: Hardness: The hardness of the material is an important factor in determining the crusher selection. Harder materials require a hammer head with better wear resistance and a more powerful power system. Humidity: Materials with high humidity are prone to blockage problems, so you need to choose a crusher with an anti-blocking design, such as a reversible hammer crusher. Structure: The structure of the material (such as fibrous, blocky, etc.) will also affect the choice of crusher. Different structures may require different types of crushing chambers and hammer head designs.

2. Consider production capacity requirements: Choose a crusher with corresponding production capacity according to the production requirements of the production line. The production capacity of reversible hammer crushers is generally higher, but there may be differences between specific models. Consider the continuous working time and load rate of the equipment to ensure that the crusher can meet the needs of long-term stable operation.

3. Consider the discharge particle size requirements: Choose a crusher with corresponding adjustment capabilities according to the product's particle size requirements. Reversible hammer crushers usually have the feature of adjustable discharging particle size, but the adjustment range may be different for different models.

4. Consider equipment quality and after-sales service: Choose a crusher from a well-known brand to ensure the quality and performance of the equipment. Well-known brands usually have a more complete after-sales service system and can provide more timely technical support and maintenance services. Understand the manufacturing process and material selection of the equipment to ensure the durability and reliability of the equipment.

5. Consider price and cost: Consider the purchase cost, operating cost and maintenance cost of the equipment. Although the price of a reversible hammer crusher may be higher, it may have lower operating costs in the long run due to its high efficiency and durability. When choosing a reversible hammer crusher, it is necessary to comprehensively consider material characteristics, production capacity requirements, discharging particle size requirements, equipment quality and after-sales service, price and cost, and other related factors. By comprehensively evaluating these factors, you can choose a reversible hammer crusher that suits your production needs.

The gap between the discharge ports can be adjusted, the discharge particle size is uniform, the output is large, and the energy consumption is low.

No screening strip, overcoming the problems of high material humidity and easy blockage.

The rotor can rotate in both forward and reverse directions to evenly wear the hammer head and crushing plate, thereby improving the utilization rate of the hammer head.

The overall performance is good, the crushing ratio is large, the production capacity is high, and the product particle size is uniform.

After the material enters the reversible hammer crusher through the feeding hopper, it encounters a high-speed rotating hammer head and is hit onto the adjustable wear-resistant toothed plate at the inlet of the crusher for the first crushing. After crushing, the material with basically the same particles enters the main crushing chamber uniformly for the second main crushing. The material particles that have been homogenized in the main crushing chamber obtain kinetic energy from the hammer head again and rush towards the toothed lining plate inside the counterattack chamber at high speed. After the upward rebound of the toothed lining plate, they are crushed again by the hammer head. At the same time, the material is also crushed by the impact between each other. This cycle is repeated multiple times in the counterattack chamber, and finally the crushed material is discharged from the discharge port. The finely crushed material is the finished product. Product granularity control is achieved by adjusting the gap between the rotor and the impact plate.

| Model | Rotor size(mm) | Input Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kw) |

| ZCHC0808 | φ800×800 | <60 | <15 | 25-40 | 90 |

| ZCHC1010 | φ1000×1000 | <80 | <15 | 35-70 | 110 |

| ZCHC1012 | φ1000×1250 | <80 | <15 | 70-80 | 132 |

| ZCHC1212 | φ1250×1250 | <100 | <15 | 90-120 | 220 |

| ZCHC1214 | φ1250×1400 | <100 | <15 | 120-150 | 250 |

| ZCHC1416 | φ1400×1600 | <120 | <15 | 160-250 | 355 |

| ZCHC1418 | φ1400×1800 | <120 | <15 | 250-300 | 400 |

| ZCHC1618 | φ1600×1800 | <140 | <15 | 280-350 | 560 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.