Construction & demolition (C&D) waste contains a wide range of recoverable fractions — concrete, bricks and aggregates, metals, wood and plastics — that, when processed correctly, reduce landfill costs and create new revenue streams.

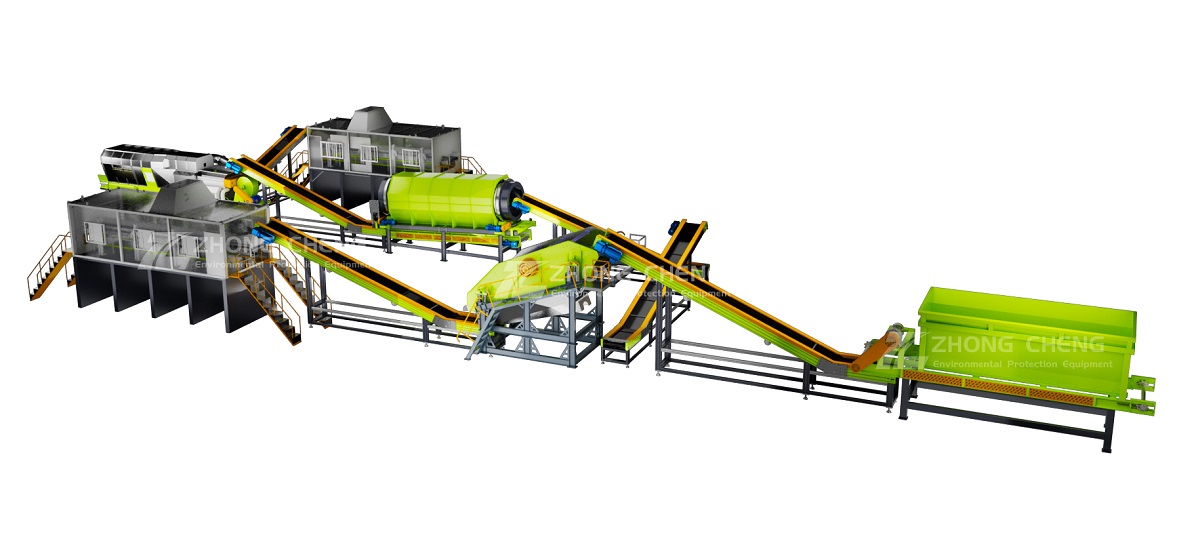

Zhongcheng Environmental Equipment provides complete C&D Recycling Systems – from waste collection to sorting and screening – helping you transform mixed construction debris into reusable resources with high purity and profitability.

Our turnkey C&D Recycling Systems are engineered to take mixed construction and demolition waste and convert it into separated, saleable fractions with high purity. Typical workflow:

Feeding & Pre-sorting — Apron feeder

Mixed C&D loads are deposited into a feed hopper and metered by a heavy-duty apron feeder (apron conveyor) — ideal for large, wet or sticky feed material and for reliable, controlled feed into downstream equipment. Manual pre-sorting (removal of hazardous items, large rebar, bulky wood panels) is combined with the apron feed to protect downstream screens.

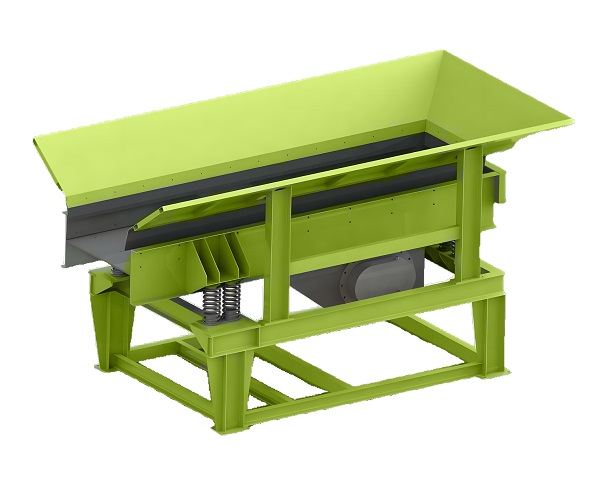

Primary Screening — Finger screens Or Ballistic Separator

Finger screens (bar sizer / finger screen) — robust for pre-screening bulky, irregular materials; excellent for separating oversize fractions and producing consistent size cuts before further processing.

Ballistic separator — an alternative that performs a 3-way separation (rigid/3D items, flexible/film-like fractions, and fines) and is especially strong when you need to separate flat/flexible plastics and paper from rigid debris. Use ballistic separation when material shape and flexibility are the main sorting criteria.

Magnetic Separation — Extract ferrous metals (rebar, nails, steel frames) using overband or drum magnetic separators.

Air / Density Separation — Light fractions (plastic film, insulation, paper) are separated from heavier mineral fractions by air classifiers or wind sifters.

Eddy Current / Non-Ferrous Separation (optional) — Recover non-ferrous metals (aluminum, copper) using eddy current separators where required.

Optical Sorting (optional advanced stage)— NIR / color optical sorters increase purity for plastic fractions or specific materials if high-value separation is required.

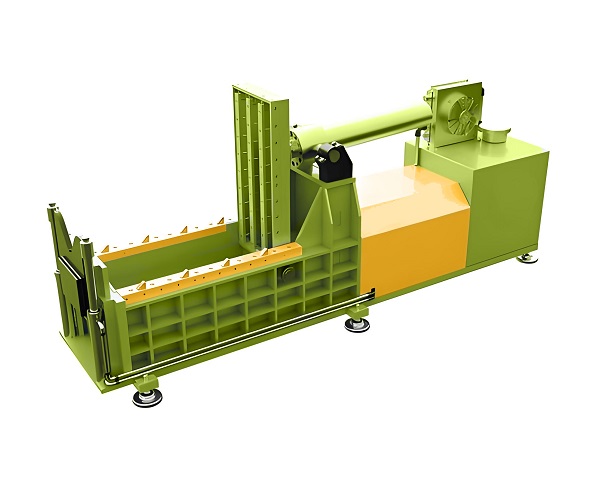

Final Screening & Storage—Cleaned aggregates, crushed concrete, wood fractions and sorted plastics are conveyed to dedicated bunkers / silos, ready for resale or reprocessing.

What Is C&D Waste?

C&D waste stands for Construction and Demolition waste, which includes debris generated from construction, renovation, and demolition of buildings, roads, and bridges.

Typical C&D waste materials include:Concrete, bricks, and stones.Wood, plastic, and glass,Metals such as steel, aluminum, and copper,Gypsum boards and insulation materials,Soil and aggregates.

Recycling these materials not only conserves natural resources but also minimizes environmental impact and disposal costs.

This is a solution for centralized waste process, which can handle a large amount of mixed demolition and construction waste, with strong production capacity, high stability and powerful functions. According to your specific needs, the entire system can include feeding and pre-screening, crushing and shredding, material sorting, cleaning, aggregate optimization, packing and compression, dust removal, water treatment and other modules.

Benefits of ZC Stationary C&D Waste Recycling Plant:

1.Maximise the recycling of construction, demolition and other solid waste.

2.Maximise the production of high quality recycled sand and aggregates that have good size and shape.

3.Minimise manual participation and reduce operating costs.

4.Flexible, equipment can be expanded when needed to increase production capacity.

5.Compact, specially optimized layout helps to save land occupation.

ZC designs waste disposal plans according to the specific needs of customers.

Craftsman's mind creates lean products

Save Time! Get A Detailed Quotation Quickly.