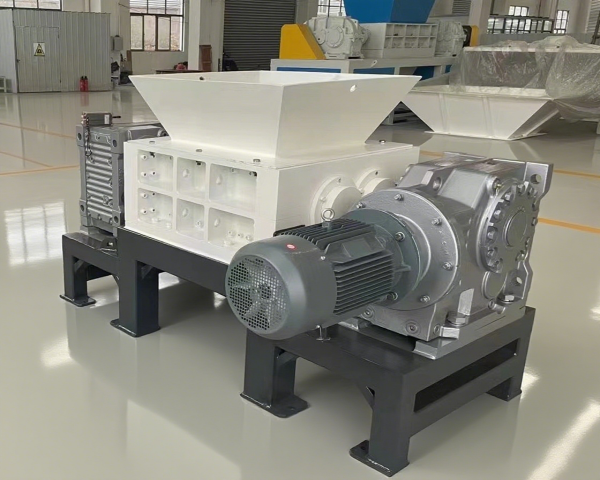

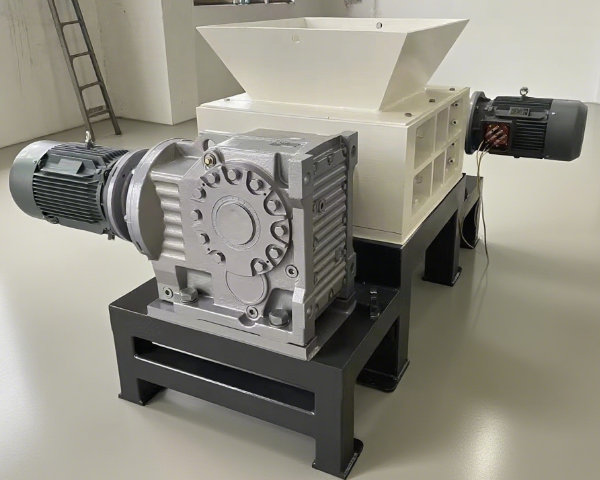

ZCF series dual-shaft shredder is specially manufactured for the treatment of biological waste. It can be used for shredding garden and kitchen waste, destroying expired food or for the disposal of slaughter waste. ZCF shredder is famous for its solid structure, super high performance and long service time. It is widely used in restaurants, hotels, supermarkets, slaughterhouses, garbage management units and so on.

Food waste accounts for about 50%-60% of domestic waste, mainly refers to the perishable, organic domestic waste generated in the daily life of residents and activities such as food processing, catering services and unit feeding, including: waste fats and oils, raw meat remnants, leftovers, bones, etc., and also includes fruit and vegetable waste from vegetable markets.

The ZCF series double-shaft shearing type shredder has strong shearing and tearing forces to shred all kinds of soft and hard food waste, is anti-corrosion and wear resistant, impact-resistant and can be operated centrally and continuously, making it easy to expand capacity and production. We can also provide professional sewage treatment system, deodorization and dust removal devices to ensure a clean operating environment and light odor.

The ZCF series shredder is an intelligent shredding plant designed by ZCEP Ecotech for the characteristics of kitchen waste, which is highly adaptable to the material and not limited by moisture. The pre-processing of the food waste through the machine provides a high sorting efficiency and a stable material for the subsequent system. This shredder is highly sought after in the market due to the large amount of food waste produced globally every day.

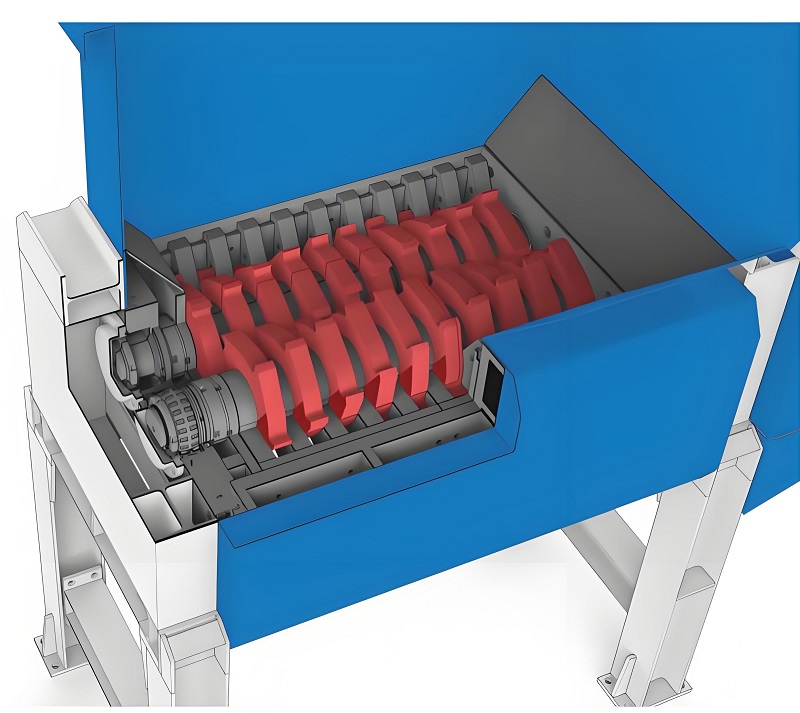

The food waste shredder mainly relies on the principle of shearing and cutting to complete the process of shredding materials. The motor drives the reducer and transmits the torque to the shredder's cutters through the cutter roller shaft, which hooks the material and tears it downwards, while the cutters on the relative rollers act like scissors to cut the material. The shredded material is discharged from the bottom of the shredder.

The blade is the core component of the shredder, and its material and structure directly affect the shredding effect and durability. Choosing blades with excellent material and reasonable structure can ensure the efficient operation and long service life of the shredder.

Understand the maintenance requirements and cycles of the shredder, choose products that are easy to maintain, and ensure the long-term stable operation of the equipment.

Choose a manufacturer or brand with a comprehensive after-sales service system, so that problems can be encountered in a timely manner during use.

Based on comprehensive consideration of the above factors, compare the prices of different brands and models of shredders and choose products with high cost-effectiveness.

Prioritize choosing well-known brands of food waste shredders, which typically have better product quality and more comprehensive after-sales service systems.

In summary, when choosing a food waste shredder, it is necessary to comprehensively consider multiple aspects such as brand, performance, safety, environmental friendliness, operation and maintenance, and cost-effectiveness. By carefully comparing and evaluating the advantages and disadvantages of different products, choose the product that best suits your needs.

The use of corrosion-resistant and highly wear-resistant compatible food waste special cutters, strong material adaptability, good shredding effect.

The assembled anti-winding fixed cutter design not only effectively solves the problem of material entanglement, but also has low maintenance cost.

Multi-bearing seal, waterproof, dirt-proof and dustproof, can directly shred wet waste with high moisture content.

Easy to operate and user-friendly, reducing operational difficulty and training costs

The working principle of a dual axis shredder is to use a rotor with two blades arranged in a spiral pattern, and the motor drives the two rotors to move towards each other. During the movement, the teeth on the rotor bite the material, pulling it into the blade and cutting and pulling it together, thus achieving the effect of shredding the material.

The materials are stacked in the feeding hopper and pushed into the crushing chamber by the screw. Under the action of negative pressure, the materials entering the crushing chamber are subjected to high-speed impact and shear by the crushing blade, as well as high-frequency vibration generated by the airflow. The crushed powder is subjected to upward airflow and enters the grading wheel. Due to the rotation of the grading wheel, the powder is subjected to both aerodynamic and centrifugal forces.

The food waste processor crushes food waste into small particles through a high-speed rotating grinder and uses water flow to discharge it from the kitchen sewage pipe. During this process, the core component of the food waste processor, the grinder, played a crucial role, while the motor provided strong power support.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| ZCF5 | 1-5 | 30-200 | 2100×1000×1900 |

| ZCF5P | 3-8 | 2500×1000×2000 | |

| ZCF6S | 4-10 | 3000×1100×2200 | |

| ZCF6 | 6-15 | 3100×1200×2500 | |

| ZCF8 | 10-20 | 4300×3200×3200 | |

| ZCF9 | 15-30 | 5400×3200×3300 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.