The ZDS series shredder is a dual-shaft shearing shredder designed by Zhongcheng Machinery specifically for bulky waste disposal. It can reduce the size of various household and office furniture, mattresses, electrical appliances waste (WEEE), and other bulky items efficiently and economically, reduce space occupation and disposal costs, improve delivery efficiency, and promote recovery recycling.

Bulky waste is a variety of bulky furniture, garden waste, etc. that is collected through specialized removal routes. Bulky waste contains many different and valuable resources which can be recovered and reintroduced into the raw material cycle as well as the generation of high-quality substitute fuel for thermal utilization.

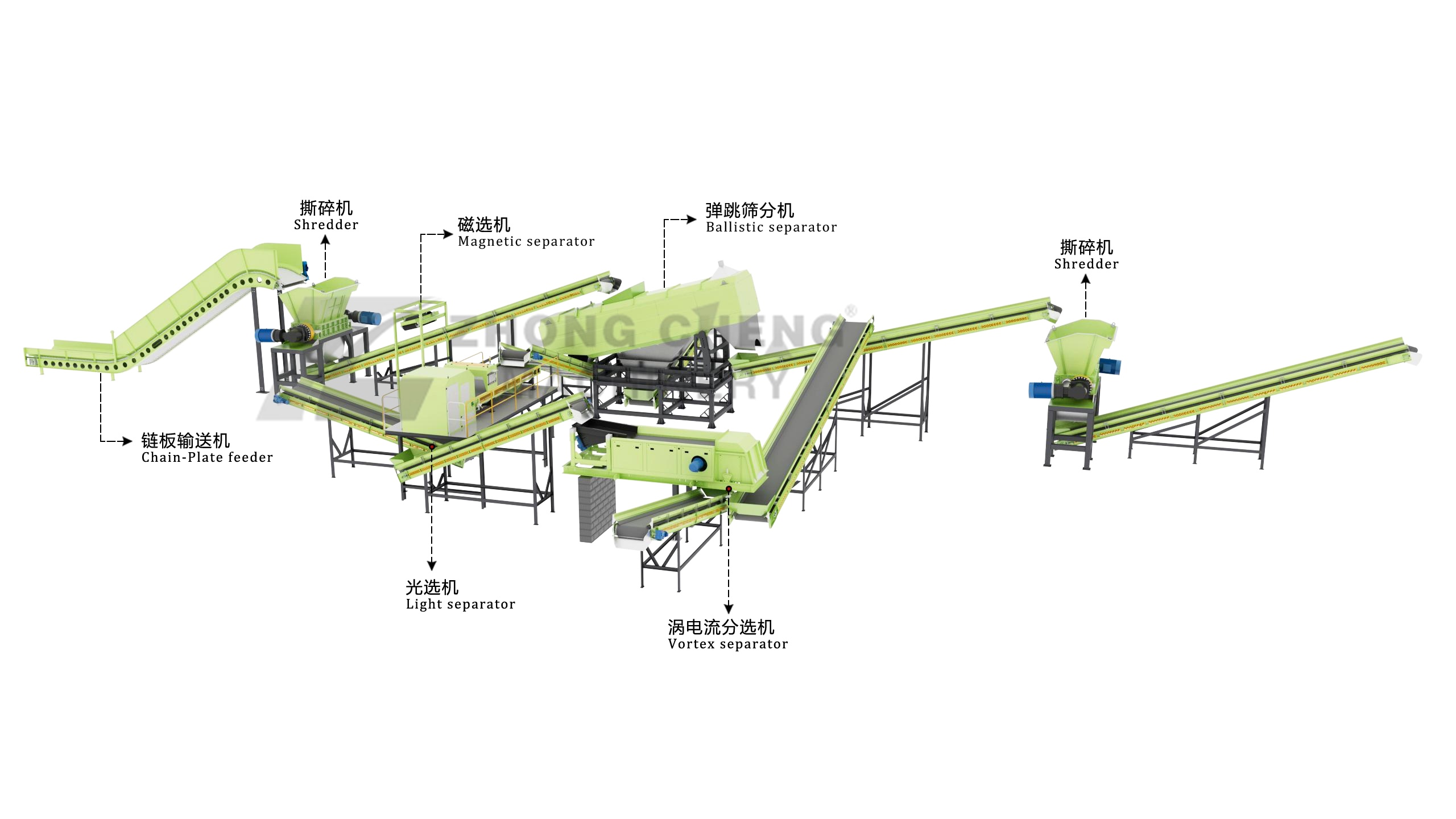

ZDS double-shaft shredders are optimized for bulky waste disposal, with large feed sizes, high shredding efficiency and easy reduction of bulky waste from a wide range of materials, and we also have sorting equipment for efficient sorting of the shredded material.

The bulky waste shredder uses double motors + double planetary reducers to drive the two cutter shafts to reduce the size of the material through the shearing, squeezing and tearing action of the blades. The distance between the cutter teeth on the blades determines the length of the shredded material, and the thickness of the blade determines the width of the shredded material.

Choosing the right double-shaft bulky waste shredder involves considering several factors based on your specific needs and the type of material you plan to shred. Here’s a step-by-step guide to help you make an informed decision:

1.Material Type and Characteristics: Type of Waste: Identify the type of bulky waste you will be shredding (e.g., furniture, mattresses, large plastics, wood, metal, etc.).Physical Properties: Consider the physical properties of the material, such as hardness, moisture content, and size.

2.Output Requirements: Desired Particle Size: Determine the desired output size or particle size after shredding. Uniformity: Decide if you need uniform particle sizes or if variability is acceptable.

3.Throughput Capacity: Processing Rate: Assess how much material you need to process per hour or day. Batch Size: Consider whether you will be processing in batches or continuously.

4.Durability and Construction: Build Quality: Choose a shredder with robust construction that can withstand the rigors of industrial use. Materials: Look for materials like high-strength steel or alloys that resist wear and tear.

Once you’ve compiled this information, you can start contacting manufacturers or suppliers to request quotes and further details. It might also be helpful to visit trade shows, read reviews, and ask for recommendations from industry peers to find a reliable supplier.

The main shaft and cutters are made of high-strength alloy steel with multi-step finishing process for long service life.

GI intelligent system can provide real-time feedback on equipment operation data and automatic alarm stop for failure to avoid accidents.

Anti-winding fixed cutter design to cope with large pieces of waste flexible textile material disposal, realizing more easily shredding.

The product features mainly include efficient crushing ability, sturdy and durable structure, wide application, and high degree of automation.

Shear or shred materials through relative motion using dual axis knife rollers. This equipment mainly consists of a knife roller, a screen mesh, a fixed knife, a loading box, a box bracket, a supply system, a power system, and an electric control system. The dual axis shredder has a low speed and high torque, making it suitable for shredding hard or bulky materials such as wood, tires, waste household appliances, metals, etc. This device is equivalent to two hammers combined into one, reasonably combined into a whole. Two sets of rotors are used in series, and the shearing or shredding of materials is achieved through the relative motion of two axes, thus achieving the purpose of crushing. The dual axis shredder is suitable for processing large amounts of waste and disposing of it in landfills.

| Model | Capacity (m³/h) | Output size (mm) | Dimension (mm) |

| ZDS450 | 10-25 | About 100~300 | 4000×1750×3000 |

| ZDS550 | 15-40 | 5000×2650×3300 | |

| ZDS750 | 20-70 | 5500×2750×3500 | |

| ZDS950 | 40-80 | 5500×2850×3600 | |

| ZDS1150 | 60-100 | 6000×3150×3800 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.