Magnetic sorting equipment mainly uses the difference between magnetic and non-magnetic materials in garbage for sorting. It has good sorting effect and can improve the recovery rate, but it may not achieve ideal sorting effect for non-magnetic materials.

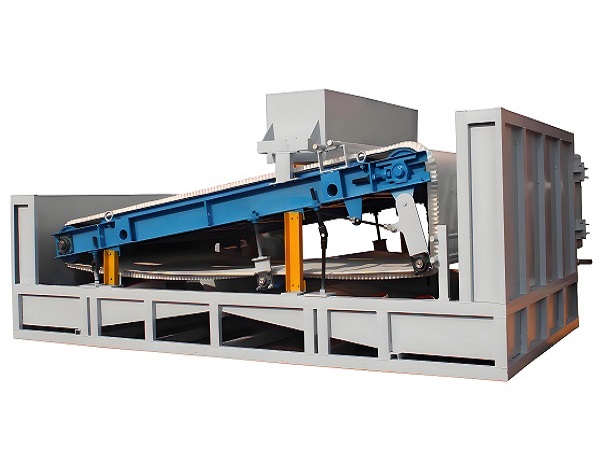

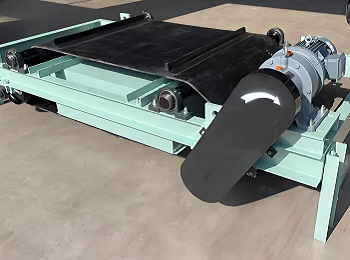

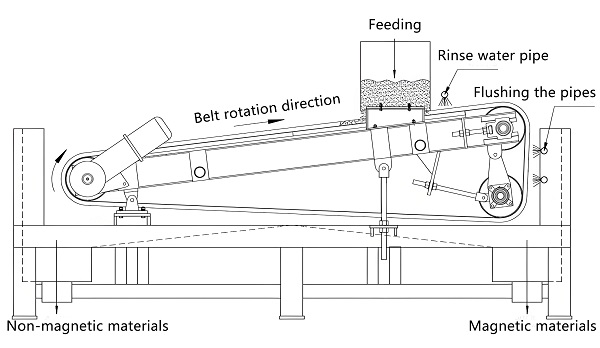

Magnetic separators use the principle of magnetic force to quickly separate iron metals from garbage, which can be further recycled and reused, reducing resource waste. The wind separator separates light waste from heavy waste through wind power, facilitating subsequent classification and processing. The screening machine screens the garbage according to its size and shape, achieving preliminary classification of the garbage. Magnetic separators also play an important role in the treatment of construction waste. The construction waste magnetic separator uses a permanent magnetic field to produce magnetic effects on metal objects in construction waste, adsorbing them onto the magnetic surface. As the transmission progresses, the adsorbed metal objects gradually pass through the transmission system to the collection system, thereby separating from non-metallic objects. This equipment mainly consists of a feeding system, permanent magnet system, transmission system, and collection system, providing a new solution for the recycling and utilization of construction waste.

1.Equipment performance: A magnetic separator with high efficiency, stability, and reliability should be selected, which has high sorting speed and accuracy, and can effectively separate various types of garbage. At the same time, the equipment should have a long service life and a low failure rate to ensure long-term stable operation. You can comprehensively understand the performance of the device by viewing its technical parameters, operating records, and user evaluations.

2.Technological maturity: Priority should be given to selecting products that have been validated through long-term practice and are technically mature and reliable. The technological maturity of a device can be determined by understanding its development history, technological updates, and the application of similar products both domestically and internationally.

3. Choose the right type of magnetic separator: Dry vs. wet: Choose the right type of magnetic separator according to the moisture content and processing requirements of the material. Dry magnetic separators are suitable for large, coarse-grained strong magnetic ores and fine-grained weak magnetic ores, while wet magnetic separators are suitable for fine-grained strong magnetic ores and fine-grained weak magnetic ores. Permanent magnet and electromagnetic: Permanent magnetic separators use permanent magnetic materials to generate magnetic fields, with simple structures and convenient maintenance; electromagnetic magnetic separators use electromagnets to generate magnetic fields, with adjustable magnetic field strength, but high energy consumption. You need to choose according to actual conditions. Other types: such as drum magnetic separators, roller magnetic separators, disc magnetic separators, etc. Each type has its applicable materials and processing requirements.

4. Clarify production needs: Understand the material characteristics: including the magnetism (strong magnetism, weak magnetism), particle size, moisture content, etc. of the ore. For example, strong magnetic minerals such as magnetite are suitable for weak magnetic field magnetic separators, while weak magnetic minerals such as ilmenite require strong magnetic field magnetic separators. Determine the processing capacity: According to the production scale of the beneficiation plant, select a magnetic separator with corresponding processing capacity. Large-scale beneficiation plants require large and efficient magnetic separation equipment to ensure production efficiency. Clarify the separation requirements: Understand the specific requirements for concentrate grade and recovery rate in order to select a magnetic separator that can meet these indicators.

5.Operating costs: While ensuring performance, operating costs should be minimized as much as possible, including equipment purchase costs, maintenance costs, energy consumption costs, etc. Attention should be paid to the energy consumption of equipment, and equipment with energy-saving and consumption reducing characteristics should be selected to reduce operating costs.

6.After sales service: An excellent garbage sorting equipment should provide comprehensive after-sales service, including equipment installation, debugging, maintenance, and upkeep. This not only ensures the normal operation of the equipment, but also reduces maintenance costs for users.

Short magnetic circuit and little magnetic flux leakage.

Adopting computer optimized design, the magnetic circuit is reasonable and strictly selected rare earth permanent magnet materials with high coercivity and high remanence, ensuring that the magnetic force does not decrease for a long time, safeguarding the long-term interests of users, and the overall structure is reliable and durable.

High magnetic intensity and low energy consumption.

The advantages and characteristics of magnetic separators mainly include energy saving and energy saving, high efficiency and low cost, compact and simple structure, light weight, small footprint, low manufacturing and operating costs, easy operation and maintenance, stable performance, high magnetic field strength, large suction force, high iron removal rate, energy saving and easy maintenance, and convenient use.

The application principle of magnetic separator in garbage sorting is mainly to use magnetic effect to separate metal objects from non-metal objects.

The working principle of a magnetic separator is based on a magnetic field system and a separation system. The magnetic field system consists of magnets, power sources, and brackets, while the separation system includes conveyor belts, rollers, and collection boxes. When garbage enters the conveyor belt, the magnetic field generated by the magnet will adsorb the iron metal and then be transported to the designated location. Non ferrous metals and garbage will be transported away from the site by conveyor belts and ultimately collected separately in collection bins. This sorting method is easy to operate, highly automated, and can effectively separate ferrous and non-ferrous metals, while quickly cleaning up garbage and improving environmental hygiene.

| Model | Magnetic field intensity (oe) | Capacity (t/h) | Power (kw) |

| CTB600X900 | 1450 | 8-15 | 1.1 |

| CTB600X1800 | 1500 | 15-25 | 2.2 |

| CTB750X1800 | 1550 | 30-45 | 3 |

| CTB900X1800 | 1650 | 35-60 | 4 |

| CTB1050X2400 | 1650 | 60-95 | 5.5 |

| CTB1200X3000 | 1650 | 80-150 | 7.5 |

| CTB1500X3000 | 1650 | 120-200 | 11 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.