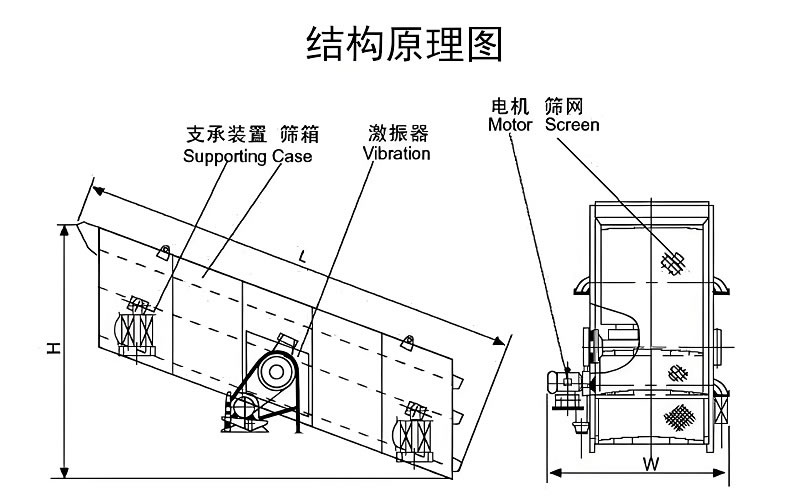

Multi layer vibrating screen is a multi-layer, circular motion vibrating screen, mainly composed of screen box, screen, vibrator, vibration damping spring device, bottom frame, etc. The side plate of the screening machine is made of high quality steel plate, the side plate is connected with the cross beam and the base of the vibrator by high strength bolts or ring groove rivets, and the amplitude is adjusted by the cylinder type eccentric shaft vibrator and eccentric block. Stable vibration source, strong vibration force, large processing capacity.

Multi layer vibrating screen are widely used and essential in mineral processing operations, construction aggregate sand and gravel production, construction waste, solid waste treatment and coal preparation industries. The electric motor makes the eccentric block of the vibrator rotate at high speed through the triangle belt. The running eccentric block produces a large centrifugal force, which excites the screening box to produce a certain amplitude of circular motion, and the material on the inclined screen surface is subjected to the impulse of the screening box and is done a continuous throwing motion. When the material meets the sieve surface, the particles smaller than the screening hole pass the screen, thus achieving grading.

The structure with small amplitude, high frequency and large inclination angle is adopted, with strong processing capacity and high screening efficiency.

Cylinder eccentric shaft vibration exciter and eccentric block are used to adjust amplitude, with stable vibration source, strong exciting force and convenient maintenance.

Rubber vibration isolation spring is adopted, with long service life and low noise.

Product serialization to meet the production requirements of customers under different process conditions; Polyurethane screen panel is modular, more versatile and more convenient to replace

Simple and compact structure, small size, lightweight, easy to install and debug. The vibration feeder is composed of a feeding trough, vibration exciter, spring support, transmission device, etc. The motor drives the driving shaft through the V-belt, and then the gears on the driving shaft mesh with the passive shaft to rotate. The active and passive shafts rotate in reverse at the same time, which makes the tank vibrate and makes the material flow continuously to achieve the purpose of conveying materials.

Multi functional application: The vibrating screen is suitable for various industries such as chemical, food, pharmaceutical, metallurgy, etc. It can effectively screen wet or dry materials, large or small particles.

Energy saving and environmental protection: The vibrating screen has low energy consumption and high energy efficiency during the screening process. In addition, due to the optimization of its structural design and operation mode, material waste and dust emissions have been reduced, which meets environmental protection requirements.

Simple and easy to maintain structure: The vibrating screen has a simple and clear structure, reasonable design, and modular design, making it convenient and fast to replace the screen mesh. In addition, the vibrating screen has fewer vulnerable parts, longer service life, and reduces maintenance costs.

Vibration screen - low noise, smooth operation, simple operation.The vibrating screen has advantages such as efficient screening, precise screening, multifunctional applications, automated operation, simple structure and easy maintenance, energy conservation and environmental protection.

This machine uses the rotation of the eccentric block in the vibrator to generate centrifugal force, causing the movable parts such as the screen box and vibrator to make forced continuous circular or approximately circular movements. The materials are continuously thrown on the inclined screen surface along with the screen box, and the materials are continuously and evenly sent to the material receiving port.

Use vibration waveforms to screen and classify materials on a sieve. When the motor drives the vibrating screen, the material on the screen will bounce on the screen due to the vibration force. The jumping distance and time of materials with different densities on the sieve are different, thus achieving separation.

The material is divided into particles of different sizes by vibration force, and then separated and filtered through sieve holes. Its characteristics are simple structure, stable operation, strong adaptability to different materials, and widely used in material screening work in industries such as coal, metallurgy, chemical, and building materials.

| Model | Feeding size(mm) | Capacity(t/h) | Power(kW) | Weight(t) | Dimension(mm) |

| 2GESY1237 | ≤100 | 5-60 | 11 | 3.1 | 4570×1900×1210 |

| 3GESY1237 | 11 | 3.4 | 4730×1900×1650 | ||

| 2GESY1548 | 11-90 | 15 | 5.6 | 5750×2180×1195 | |

| 3GESY1548 | 15 | 6.4 | 5910×2180×1650 | ||

| 4GESY1548 | 18.5 | 6.7 | 6070×2180×2085 | ||

| 2GESY1848 | 15-100 | 18.5 | 6.65 | 5742×2542×1195 | |

| 3GESY1848 | 18.5 | 6.95 | 5908×2542×1650 | ||

| 4GESY1848 | 18.5 | 7.25 | 6080×2550×2105 | ||

| 2GESY1860 | 25-130 | 22 | 7.52 | 7140×2630×2309 | |

| 3GESY1860 | 22 | 7.72 | 7140×2630×2409 | ||

| 4GESY1860 | 22 | 7.98 | 7140×2630×2550 | ||

| 2GESY2160 | 35-200 | 30 | 10.2 | 7157×2980×1680 | |

| 3GESY2160 | 30 | 10.5 | 7156×2980×1780 | ||

| 4GESY2160 | 30 | 10.8 | 7330×2980×2240 | ||

| 2GESY2460 | 50-260 | 30 | 10.5 | 6989×3280×1320 | |

| 3GESY2460 | 30 | 10.8 | 7175×3280×1828 | ||

| 4GESY2460 | 37 | 11.1 | 7375×3280×2240 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.