ZMS Series Shredder is a multi-purpose dual-shaft shredder for reducing industrial and commercial wastes. It shreds various materials into optimum shapes and sizes for recycling, incineration, or landfill. ZMS has unimaginable stability and is always reliable, which makes it possible to cope with the demand for waste disposal under the harshest working conditions.

Industrial and commercial waste is the solid waste generated from the activities of production and business units. It has a complex composition and may contain various plastics, cardboard, metals, fibers, leather, wood, glass, etc. These materials have a high value for reuse and can be recycled after treatment, into waste-to-energy incineration plants or made into refuse-derived fuels.

ZMS series of industrial waste shredders are ideal for cutting commercial and industrial waste, and for some hazardous solid waste generated by industry and commerce, we have additional specialized equipment for safe disposal.

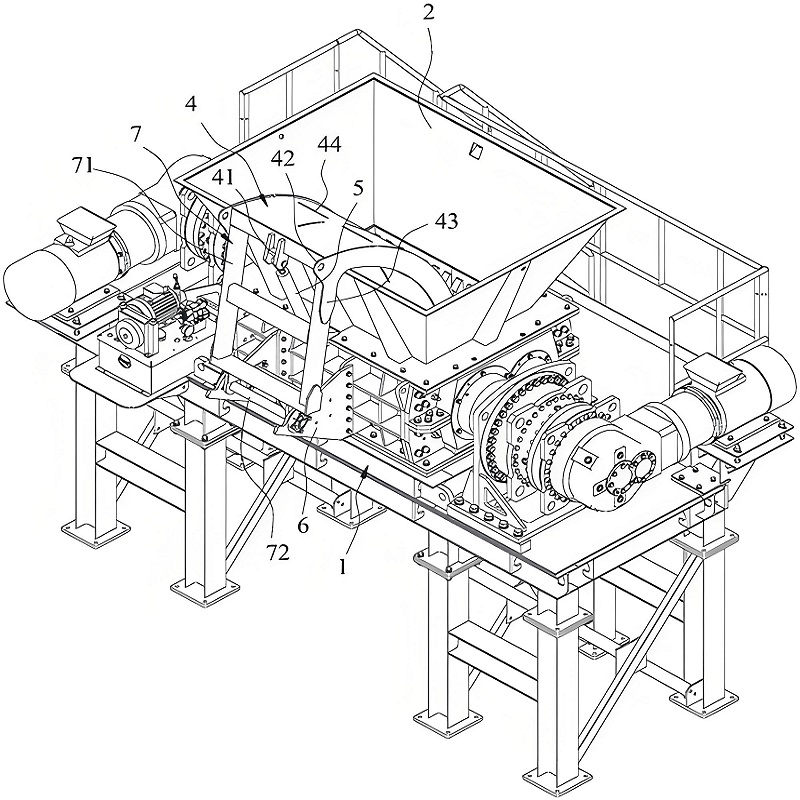

The industrial waste shredder mainly relies on the principle of shearing and cutting to complete the process of shredding materials. The motor drives the reducer and transmits the torque to the shredder's cutters through the cutter roller shaft, which hooks the material and tears it downwards, while the cutters on the relative rollers act like scissors to cut the material. The shredded material is discharged from the bottom of the shredder.

Choosing the right double-shaft industrial waste shredder involves considering several factors based on your specific needs and the type of material you plan to shred. Here’s a step-by-step guide to help you make an informed decision:

1.Identify what kind of waste you will be shredding (e.g., plastics, paper, wood, metals, e-waste, etc.).Consider the physical properties of the material like hardness, moisture content, and size.

2.Determine the desired output size or particle size after shredding.Decide if you need uniform particle sizes or if variability is acceptable.

3.Choose a shredder with robust construction that can withstand the rigors of industrial use.Look for materials like high-strength steel or alloys that resist wear and tear.

4.Evaluate the cutting mechanism (e.g., rotating knives, hinged cutters, etc.) and consider its suitability for your materials.Ensure the cutting system can handle the volume and type of waste without frequent maintenance.

Once you’ve compiled this information, you can start contacting manufacturers or suppliers to request quotes and further details. It might also be helpful to visit trade shows, read reviews, and ask for recommendations from industry peers to find a reliable supplier.

Multi-combination seal protects the bearings from complex materials and has a longer service life.

Heat-treated and high-precision machined integral cutter box, not easy to deform, more load-bearing capacity, smooth working conditions.

Unique anti-winding device, able to cope with industrial waste of mixed composition and enhance the efficiency of material shredding.

A double-shaft industrial waste shredder is a powerful machine designed to reduce the size of various types of waste materials into smaller, more manageable pieces.

The working principle of a double-shaft industrial waste shredder is quite straightforward and relies on the mechanical action of interlocking cutting blades. Here’s a detailed explanation of how these shredders work:

1. Material Feeding: The waste material is fed into the hopper at the top of the shredder. Depending on the design, a pusher or conveyor system may assist in feeding the material into the shredding chamber.

2. Shredding Process: As the material enters the shredding chamber, the rotating shafts begin to engage with the material.The interlocking cutting tools on each shaft shear the material as they pass each other.The cutting action can be a combination of shearing, tearing, and compressing, depending on the design and configuration of the knives.

3. Particle Size Control: The size of the shredded particles can be controlled by adjusting the spacing between the knives or using screens.Screens or grates at the bottom of the shredding chamber allow only particles of a certain size to pass through, ensuring uniformity in the output.

4. Discharge:Once the material is shredded to the desired size, it falls through the screen and is discharged from the shredder. A conveyor system, auger, or chute may be used to transport the shredded material away from the shredder.

5. Safety and Maintenance:Safety features prevent the shredder from starting if the access doors are open or if there are any issues with the machine.Regular maintenance is necessary to clean the shredder, replace worn knives, and perform general upkeep.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| ZMS8 | 5-10 | 100-300 | 5000×2650×3300 |

| ZMS9 | 8-15 | 5300×2750×3400 | |

| ZMS10 | 10-20 | 5500×2850×3500 | |

| ZMS12 | 15-30 | 6000×3250×3600 | |

| ZMS13 | 20-40 | 6400×3500×4000 | |

| ZMS15 | 30-50 | 6900×3700×4500 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.