Mobile impact crusher is an integrated crushing equipment that combines the functions of an impact crusher with the convenience of a mobile platform. This type of crusher is widely used in industries such as construction waste recycling, mining, road construction, and quarrying.

Mobile impact crusher is a highly integrated crushing equipment that combines the powerful crushing capacity of the impact crusher with the flexibility of the mobile platform. This type of crusher is widely used in industries such as construction waste recycling, mining, road construction, and quarrying. Here are some basic information about mobile impact crushers:

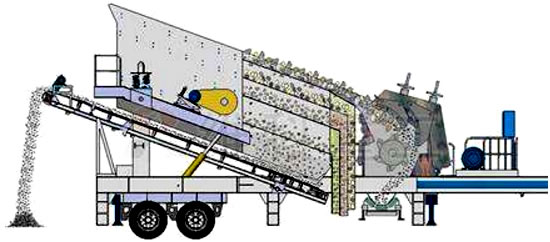

The mobile impact crusher integrates the crushing host (impact crusher), feeder, vibrating screen, conveyor belt, etc. on one platform to form a complete crushing system.

Usually, tire or track type chassis is used to facilitate quick movement between different work locations, reducing transportation costs and installation time. Has good maneuverability and can adapt to complex construction site environments.

Efficient and energy-saving: Equipped with high-performance impact crushers, it can achieve efficient material crushing.

Strong adaptability: can handle materials of various hardness, including but not limited to river pebbles, limestone, granite, etc.

The working principle of a mobile impact crusher is mainly to accelerate the material to hundreds of times the gravitational acceleration through a high-speed rotating impeller, and then impact it onto the crushing chamber wall or another high-speed moving material, using the mutual collision between materials to achieve crushing.

Mobile impact crushers have been widely used in many industries due to their high efficiency and flexibility. When choosing, the most suitable model and configuration should be determined based on specific production needs, material properties, and budget factors.

There are two kinds of mobile impact crusher, crawler type and tire type. Different types of stationary impact crushers can be configured as required, or they can be mounted on the same vehicle together with the vibrating screen to realize the integration of crushing and screening. According to the working structure, which configuration should be selected, the user can consult Zhongcheng Machinery engineer online, and we can provide you with model selection and crushing plant planning services for free.

The mobile impact crusher does not need to make concrete foundation. It can be pulled and moved and be used immediately. The tire-type mobile impact crusher is pulled by a semi-trailer,which is convenient for narrow sites. Crawler-type mobile impact crusher plant can move by itself, and it can be remotely controlled. Compared with wheel type, the transition mobility is more flexible;

You can also choose a single impact crushing machine, or an integrated configuration of impact crushing and screening plant. The mobile impact crusher can also work together with other mobile equipment, and multiple units can work in parallel to form a graded crushing and mobile crushing production line.

The mobile impact crusher can be used alone, but if the particle size of the raw material is too large, it is usually used in combination with the mobile jaw crusher.

Visiting factories: If conditions permit, visit equipment manufacturers' factories or actual customer usage sites.

Consult industry professionals or seek advice from equipment suppliers. Detailed understanding of the technical parameters and technical support of the equipment.

Compact structure, small footprint, suitable for workplaces with limited space.

Usually, tire or track type chassis is used to facilitate quick movement between different work locations, reducing transportation costs and installation time.

Different crushing configurations can be selected according to different process requirements, such as coarse crushing, medium crushing, or sand making operations.

Highly integrated, easy to move, efficient and energy-saving, strong adaptability, flexible configuration, and reduced operating costs

The working principle of a mobile impact crusher is mainly to accelerate the material to hundreds of times the gravitational acceleration through a high-speed rotating impeller, and then impact it onto the crushing chamber wall or another high-speed moving material, using the mutual collision between materials to achieve crushing.

The mobile cone crusher is driven by an electric motor to rotate the eccentric sleeve, causing the moving cone to rotate and swing inside the crushing chamber, thereby squeezing, rolling, and crushing the material. The crushed material is processed by a screening system to obtain finished materials that meet the requirements.

| SMC Impact crusher | SMC1010PFS | SMC1210PFS | SMC1214PFS | |

| Transport size | ||||

| Length(mm) | 10800 | 12200 | 12500 | |

| Width(mm) | 2480 | 2743 | 2900 | |

| Height(mm) | 4170 | 4200 | 4200 | |

| Alex weight(kg) | 15900 | 17200 | 22100 | |

| King pin weight(kg) | 11300 | 14300 | 17500 | |

| Impact crusher | ||||

| Model | PF1010 | PF1210 | PF1214 | |

| Feed opening(mm) | 400X1080 | 400X1080 | 400X1080 | |

| Vibrating screen | Vibrating screen | |||

| Model | 4YK1235 | 4YK1545 | 4YK1548 | |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.