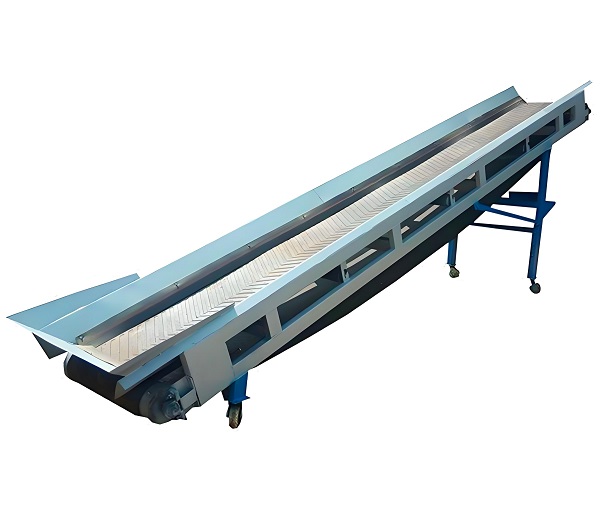

ZBC series belt conveyor is a kind of equipment driven by friction to transport loose materials or finished articles in a continuous manner. It can be used for horizontal or inclined transport. It has the advantages of simple structure, economy and convenience, reliable use, stable transmission, large conveying volume, high conveying efficiency, low noise, etc., and is convenient for programmed control and automatic operation.

ZBC series belt conveyor is widely used in metallurgy, coal, transportation, hydropower, chemical industry, building materials, light industry, grain and other departments. With the rise of the environmental protection industry, it is widely used in industrial waste, domestic waste, construction waste, medical waste, automobile disassembly, battery recycling and other production lines.

The belt conveyor is mainly composed of two end drums (driving drum and reversing drum) and a closed conveyor belt which is tightly sleeved. The driving roller is driven by the motor through the reducer, and the conveyor belt is driven by the friction between the driving roller and the conveyor belt. The material is fed from the feeding end and falls on the rotating conveyor belt. It is driven by the friction of the conveyor belt and transported to the unloading end for unloading.

When choosing a belt conveyor, multiple factors need to be considered to ensure that the selected equipment can meet specific application requirements. Here are some key selection steps and considerations:

1. Consider conveying materials: Determine the type, weight, volume, as well as physical and chemical properties of the materials to be conveyed. This helps in selecting the appropriate material, structure, and size for the conveyor belt.

2. Consider the working environment: Consider the working environment of the conveyor, such as temperature, humidity, corrosiveness, explosiveness, etc., to choose the appropriate protection level and materials.

3. Choose the appropriate type of conveyor, such as those used in industries such as electronic plastics, food and light industry, chemical and pharmaceutical industries, which usually have smaller sizes and weights.

4. Pay attention to the idlers and rollers of the conveyor: The quantity, layout, and material of idlers and rollers have a significant impact on the operational stability and lifespan of the conveyor. Ensure that they have good wear resistance and corrosion resistance.

5. Consider maintenance and upkeep: Consider the maintenance and upkeep needs of the conveyor, choose equipment types that are easy to maintain and upkeep, in order to reduce operating costs and improve equipment lifespan.

The equipment operates stably and reliably, and is easy to realize automation and centralized control.

The structure is simple, the rack is light, the disassembly is very convenient, the maintenance is convenient, small energy consumption, and low cost.

According to the requirements of the conveying process, it can be transported by a single machine, or it can be jointly operated by a multi-unit synthetic conveying system.

Large conveying capacity, small power consumption, large conveying distance and easy layout.

The working principle of a belt conveyor is relatively intuitive and efficient, and its core lies in the continuous conveying of materials through the collaborative action of a series of mechanical components. The following is a detailed explanation of the working principle of a belt conveyor:

A belt conveyor is mainly composed of a driving device, a conveyor belt, a conveyor drum (including an active drum and a reversing drum), a tensioning device, a support roller, a frame, and possible unloading and cleaning devices. The working principle can be summarized as follows: the driving device drives the active drum to rotate, and the active drum drives the conveyor belt to move through friction. The material is loaded onto the conveyor belt and moves with it, and finally unloaded to the destination through the unloading device.

| MODEL | BC800 | BC1000 | BC1200 | BC1400 | BC1600 |

| Belt Width | 800mm | 1000mm 1 | 200mm | 1600mm | 1800mm |

| Length | optional | optional | optional | optional | optional |

| Belt Speed | <1.2m/s | <1.2m/s | <1.2m/s | <1.2m/s | <1.2m/s |

| Installation | angle < 21° | angle < 21° | angle < 21° | angle < 21° | angle < 21° |

| Throughput | 20-30m³/h | 40-50m³/h | 60-70m³/h | 80-90m³/h | 90-100m³/h |

| Power | >3Kw | >3Kw | >3Kw | >3Kw | >3Kw |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.