The ZBS series double-shaft shredder is specially designed to handle waste from municipal green waste, rootstocks, untreated waste wood, straw or fruit shells of crops, etc. It can quickly shred biomass materials into small pieces. ZBS double-shaft shredder has high output and reliable performance, widely used in biomass cogeneration power stations.

Biomass is a renewable organic material of plant and animal origin and is an important alternative fuel for electricity or heat generation. The high value of biomass and the low cost of disposal are receiving increasing attention, and there are now many power stations around the world dedicated to burning biomass.

ZBS offers cost effective biomass pre-shredding equipment, the GDB range of double-shaft shredders are ideal for the integrated use of biomass due to their ability to process material to a small size in a single pass, high capacity disposal, intelligent maintenance and continuous operation. the ZBS double-shaft shredder blade set is optimized for the processing of lignin and cellulose and is cost effective and durable.

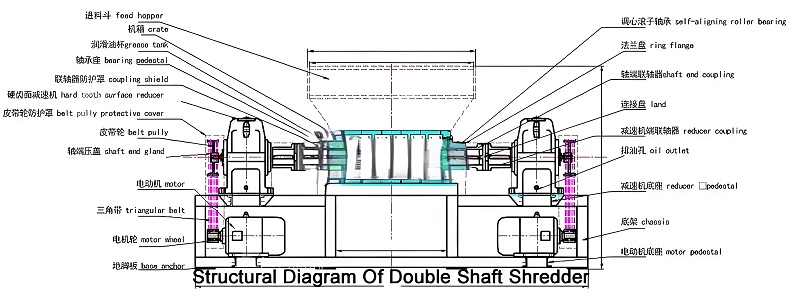

The biomass shredder is driven by a motor that drives two cutter shafts that rotate the cutter and sleeve at low speed. The shearing effect is achieved by the shearing of the adjacent cutter face edges on the cutter shaft, the shearing of the cutter tip against the cylindrical surface of the sleeve and the tearing by the torque and speed difference of the cutter shaft.

When choosing a dual axis biomass crusher, the following aspects need to be considered to ensure the selection of equipment with stable performance, high efficiency, and suitable for one's own needs:

2.Firstly, determine the type of biomass that needs to be crushed, such as straw, wood, and waste household appliances, as different materials have different requirements for the crusher.

2. Determine the required crusher production capacity based on production scale or processing capacity, such as how many tons of material can be processed per hour.

3. Clarify the particle size requirements for the crushed material in order to select the appropriate machine model.

4. The motor is the power source of the crusher, and its power and stability directly affect the operating efficiency and service life of the equipment. Choose motors from well-known brands, with moderate power and stable operation.

5. The blade is the core component of the crusher, and its material and cutting ability directly affect the crushing effect and blade life. Choose blades with excellent material and strong cutting ability.

Shaft and cutter are made of high-strength alloy steel with multi-step finishing process for long service life.

Unique anti-winding fixed cutter Unique anti-winding fixed cutter design, effectively solving the problem of wrapping material entanglement and improving shredding efficiency.

GI intelligent monitoring system, which can monitor the operation condition in real time; fault warning indication, escorting for long time continuous work.

Double axis shredder, as a variant of shredder, has higher efficiency and applicability.

The working principle of a dual axis shredder can be clearly described in the following steps:

Equipment composition:

The dual axis shredder is mainly composed of rotors with two blades arranged in a spiral pattern, which are symmetrically arranged to ensure that the material can be processed uniformly and effectively.

The rotor is equipped with blade teeth for biting and shredding materials.

Power driven:

After the motor slows down through the reducer, it obtains a large torque, which is used to drive the two rotors to move towards each other.

Due to the function of the reducer, the high-speed rotation of the motor is converted into low-speed high torque rotation of the rotor, ensuring effective shredding of materials.

Tearing process:

During the movement, the teeth on the rotor will bite onto the material and pull it between the blades.

The material is subjected to shearing and pulling forces between the blades, thereby achieving the effect of shredding the material.

The degree of shredding depends on the thickness of the blade and the number of teeth. Generally speaking, the thinner the blade thickness, the smaller the size of the shredded material; The more teeth there are, the shorter the length of the shredded material.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| ZBS115 | 8-25 | 50~200 | 6000×3300×4000 |

| ZBS215 | 20-30 | 6500×3500×4300 | |

| ZBS315 | 30-60 | 6900×4000×4700 | |

| ZBS415 | 50-70 | 7000×4300×4800 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.