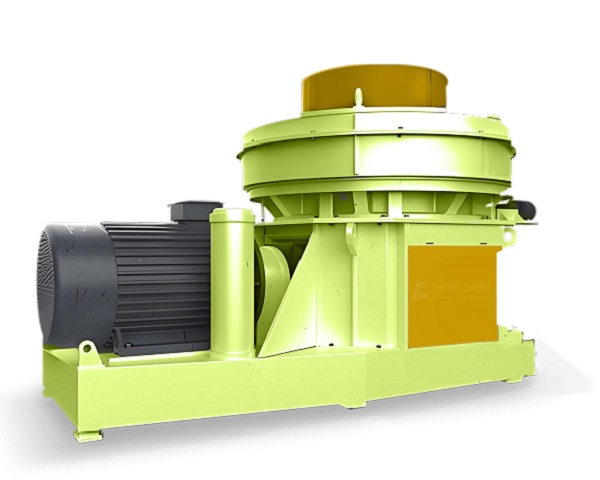

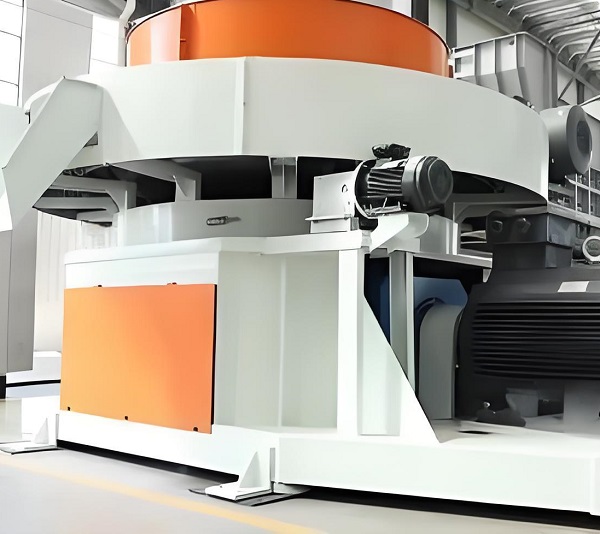

RDF pelletizer is a mechanical equipment that processes waste-derived fuel into pellets. Zhongcheng Machinery's RDF pelletizer products are diverse, including vertical and horizontal models to meet the needs of waste treatment of different scales and types. RDF pelletizers are widely used in agriculture, industry, environmental protection and other fields, providing an effective means for the resource utilization of solid waste.

RDF pelletizer is a kind of equipment specially used to convert various types of waste materials into granular fuel. RDF pelletizer mainly uses physical compression to send waste materials such as plastics, paper, fiber, organic garbage, etc. into the compression chamber of the pelletizer after crushing, sorting, drying and other pre-treatment. Under the action of high pressure, these waste materials are compressed into granular fuels with a certain shape and size.

RDF pelletizers can be divided into many types according to their structure and purpose, such as vertical and horizontal. These different types of pelletizers are suitable for waste treatment needs of different scales and types. The manufactured RDF pellet fuel is widely used in cement plants, power plants, steam boilers and other industries as a fuel to replace coal or natural gas, which helps to save energy costs and reduce environmental pollution.

Features and advantages of RDF pelletizer

1. High efficiency and energy saving: RDF pelletizer adopts advanced compression technology, which can efficiently convert waste materials into granular fuel and improve energy utilization efficiency.

2. Environmental protection and emission reduction: Through the resource utilization of waste, RDF pelletizer helps to reduce environmental pollution caused by landfill and incineration, and realize the reduction, harmlessness and resource utilization of waste.

3. Strong adaptability: RDF pelletizer is suitable for a variety of waste materials, can handle waste of different types and properties, and has strong adaptability.

4. Easy operation: The operation of the pelletizer is simple and easy to learn, easy to maintain and maintain, and reduces the operating cost.

RDF pelletizer plays an important role in the resource utilization of waste, and has broad market prospects and application value.

1. Consider capacity requirements: First, clarify your own capacity requirements, that is, how much raw material needs to be processed per hour. This helps to choose an RDF Pelleting Mill with corresponding production capacity.

2. Consider raw material type: Understand the type, moisture content, particle size and other characteristics of the raw materials, because different raw materials may require different types of molding machines and different processing processes.

3. Consider molding effect: Examine the molding effect of the equipment, including the uniformity, density, strength, etc. of the particles. A high-quality RDF molding machine should be able to produce particles with regular shapes and stable quality.

4. Consider energy consumption and efficiency: Pay attention to the energy consumption level and production efficiency of the equipment. Energy-efficient equipment can reduce operating costs and improve economic benefits.

5. Consider stability and reliability: Choose equipment with good stability and reliability, reduce failure rate and downtime, and ensure the continuity and stability of production.

6. Consider motor power and speed: Motor power and speed are important factors affecting the production capacity of the equipment. Select the appropriate motor power and speed according to production needs.

It is convenient to adjust the radial clearance between the pressure roller and the mold, and ensure the proper clearance between the pressure roller and the mold.

The number of die apertures is large and the processing capacity is large; Simple structure, simple and convenient maintenance, low maintenance frequency.

Dynamic heating molding, good molding effect; Pressure forming, the lock type of the finished product is not loose.

RDF Pelleting Mill is an ideal choice for processing raw materials such as RDF due to its high efficiency, versatility, high degree of automation, environmental protection and energy saving, as well as high-quality pellet products.

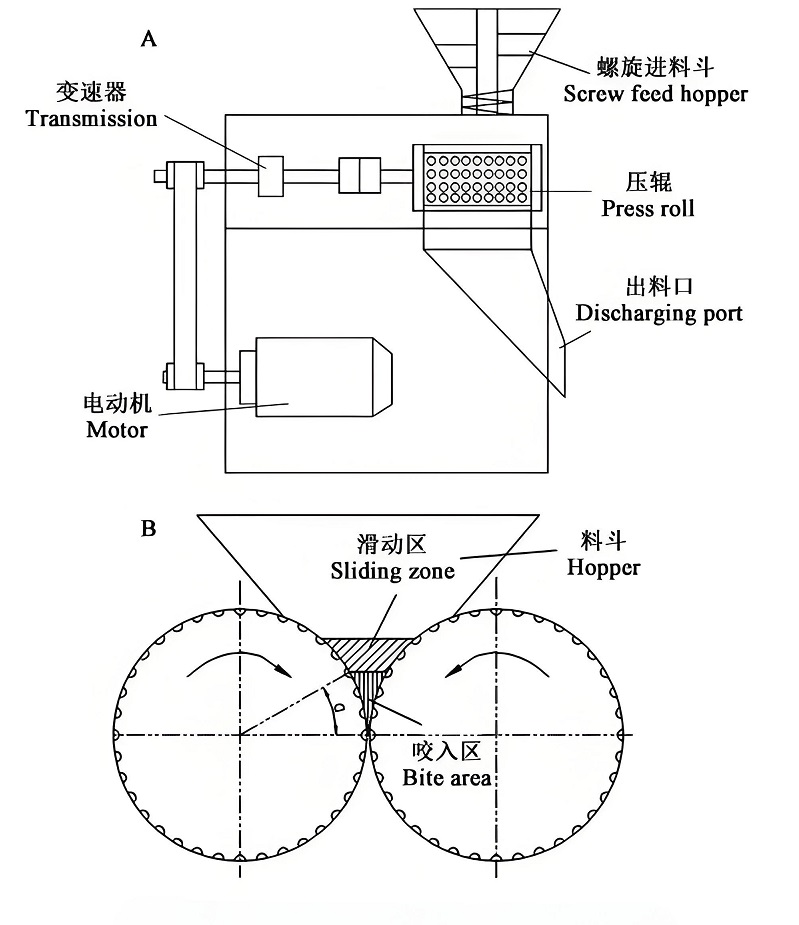

The working principle of RDF Pelleting Mill mainly involves the steps of raw material transportation, compaction, molding and automatic control. The following is a detailed description of the working principle:

1. Raw material transportation

The RDF molding machine first transports raw materials such as agricultural waste and solid waste to the next stage through the conveying system. The conveying system is responsible for ensuring that the raw materials can enter the compaction system stably and continuously.

2. Raw material compaction

In the compaction system, the raw materials are treated with high pressure and compacted into strips. This step is to increase the density of the raw materials and provide conditions for subsequent molding. The compaction process is crucial to ensure the quality of renewable fuel.

3. Molding process

The compacted raw materials enter the molding system. The molding system further processes the raw materials into particles of uniform size and regular shape through specific molds and mechanical actions. In this step, the selection and adjustment of parameters such as temperature, pressure, time and motion control are very critical, which will directly affect the performance and quality of renewable fuel.

4. Automatic control

RDF molding machines are usually equipped with an electronic control system, which is responsible for the automatic control of the entire production process. The electronic control system can monitor and adjust the operating status of the equipment in real time to ensure the stability and reliability of the production process. At the same time, it can also provide fault diagnosis and alarm functions to detect and solve potential problems in a timely manner.

5. Environmental protection and high efficiency

During the working process, the RDF forming machine realizes the resource reuse of raw materials such as agricultural waste and solid waste, reducing environmental pollution. At the same time, due to its efficient production capacity and automated control method, it reduces labor costs and time costs and improves production efficiency.

Summary

The working principle of RDF Pelleting Mill is based on the steps of raw material transportation, compaction, molding and automated control. Through technical means such as high-pressure compaction and low-temperature heat treatment, various raw materials are converted into high-quality renewable fuels. This equipment is not only environmentally friendly, but also can improve resource utilization efficiency and production efficiency. It is one of the indispensable important equipment in modern industrial production.

| Model | Quantity of Molds(pcs) | Forming Fuel Specifications(mm) | Processing Capacity(t/h) | Main Power(kw) |

| ZCM-52 | 52 | 32×32 | 0.8-2.5 | 75-160 |

| ZCM-102 | 102 | 32×32 | 2.5-6.0 | 160-200 |

| ZCM-136 | 136 | 32×32 | 3.5-8.0 | 185-250 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.