The vibratory feeder is widely used in industry feed to the crusher, sorting machinery, screening equipment, transport machinery, and packaging machinery.Designed for uniform conveying of bulk materials before coarse crusher in crushing and screening. The feeder can be divided into steel plate and grating structures. The Steel Plate Structure Feeder is mostly used in sand and stone production. The material can be uniformly fed into the crushing equipment. The Grate Structure Feeder can coarse screen the material, makes the system more economical and reasonable, and has been used as essential equipment in crushing and screening.

The vibrating feeder is a kind of equipment that can feed block and granular materials uniformly and continuously from the storage silo to the receiving device. It is widely used in the crushing and screening joint devices of the metallurgy industry, mining industry, construction industry, chemical industry, etc., and can be mainly divided into the steel plate structure and grate structure. The former one is more used in stone crushing plants for continuously feeding stone into the crushing mill, while the vibrating feeder with a grating structure can coarsely screen the materials. It makes the feeding system more economical and reasonable in configuration and has been used as an indispensable device in the crushing and screening process.

The industrial vibrating feeder produced by our company can adjust the feeding quantity stepless and realize the centralized control and automatic control of the feeding system. It is small in size, light in weight, and easy to install. Besides, it has a high working frequency and less energy consumption, with no rotating parts and no need for lubrication.

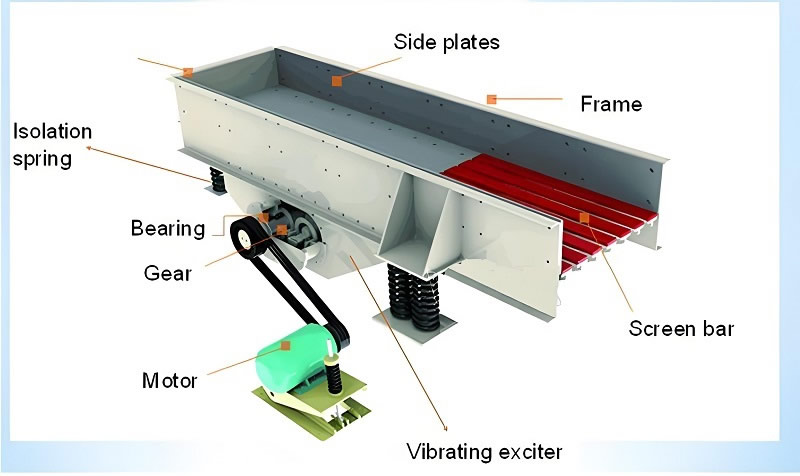

The vibrating feeder uses the centrifugal force generated by the rotation of the eccentric block to make some movable parts, such as the frame and the screen bar, move continuously. The vibrating exciter is the vibration source of the whole equipment. It is composed of two eccentric shafts and one gear. When the motor drives the driving shaft through a triangle belt, gears on the driving shaft will engage to rotate the passive shaft. Then the two shafts rotate in reverse at the same time, making the frame vibrate and the material flow continuously to achieve the purpose of material conveying.

When choosing a vibrating feeder, multiple factors need to be considered to ensure that it meets production needs and has good performance. Here are some key selection points:

1. Understand material characteristics: Consider the type, particle size, density, humidity, and other properties of the material. Different materials may require different types of vibrating feeders.

2. According to production capacity: Select the appropriate vibration feeder model and specifications based on the production line's capacity requirements.

3. Adapt to the work environment: Evaluate the temperature, humidity, dust and other conditions in the work environment, as well as whether special designs such as explosion-proof and anti-corrosion are needed.

4. Consider equipment types: There are multiple types of vibrating feeders, such as slot type vibrating feeders, tube type vibrating feeders, etc. Choose the appropriate type according to actual needs.

In summary, when choosing a vibrating feeder, it is necessary to comprehensively consider application scenarios and requirements, device types and structures, performance parameters, device quality and brand, as well as other factors. By comprehensively evaluating these factors, it can be ensured that the selected equipment can meet production needs and have good performance.

The material moves forward continuously according to the parabolic track, so the trough wears little.

Because the material flow can be changed and closed instantaneously, the feeding quantity has high accuracy.

It has a low bearing load. Due to the strong vibration of the trough, the phenomenon of material blocking the sieve hole is reduced, so that the sieve has a higher screening efficiency.

It features a simple structure, lightweight, low noise, steady running, large feeding capacity, low cost, easy installation, and maintenance.

The vibrating feeder is a kind of equipment that can feed block and granular materials uniformly and continuously from the storage silo to the receiving device. It is widely used in the crushing and screening joint devices of the metallurgy industry, mining industry, construction industry, chemical industry, etc., and can be mainly divided into the steel plate structure and grate structure. The former one is more used in stone crushing plants for continuously feeding stone into the crushing mill, while the vibrating feeder with a grating structure can coarsely screen the materials. It makes the feeding system more economical and reasonable in configuration and has been used as an indispensable device in the crushing and screening process.

| Model | Maximum Feeding Size(mm) | Capacity(t/h) | Power(kW) | Installation Angle(°) | Weight(kg) | Trough Size(mm) | Dimension(mm) |

| GZG-650×2300 | 300 | 80 | 1.1×2 | 10 | 2798 | 650×2300 | 2300x1360x780 |

| GZG-750×2500 | 350 | 100 | 1.1×2 | 10 | 3260 | 750×2500 | 2500x1460x780 |

| GZG-850×3000 | 400 | 120 | 3×2 | 10 | 3607 | 850×3000 | 3110x1800x1600 |

| GZG-1000×3600 | 500 | 150 | 5.5×2 | 5 | 3895 | 1000×3600 | 3850x1950x1630 |

| GZG-1100×4200 | 580 | 240 | 5.5×2 | 5 | 4170 | 1100×4200 | 4400x2050x1660 |

| GZG-1100×4900 | 580 | 280 | 7.5×2 | 5 | 4520 | 4900×1100 | 5200x2050x1700 |

| GZG-1300×4900 | 650 | 450 | 11×2 | 5 | 5200 | 4900×1300 | 5200x2350x1750 |

| GZG-1500×5600 | 1050 | 450-800 | 12×2 | 10 | 7500 | 1500×5600 | 5700x2000x1750 |

| ZSW-380×95 | 500 | 100-160 | 11 | 0 | 4823 | 3800×960 | 3920x1640x1320 |

| ZSW-490×110 | 630 | 150-320 | 15 | 0 | 6647 | 4900×1100 | 4980x1830x1320 |

| ZSW-600×130 | 750 | 400-600 | 22 | 0 | 9250 | 6000×1300 | 6082x2580x2083 |

| ZSW-600×150 | 800 | 500-700 | 30 | 0 | 10190 | 600×1500 | 6086x2662x1912 |

| ZSW-600×180 | 800 | 700-1000 | 37 | 0 | 13750 | 600×1800 | 6310x3262x2230 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.