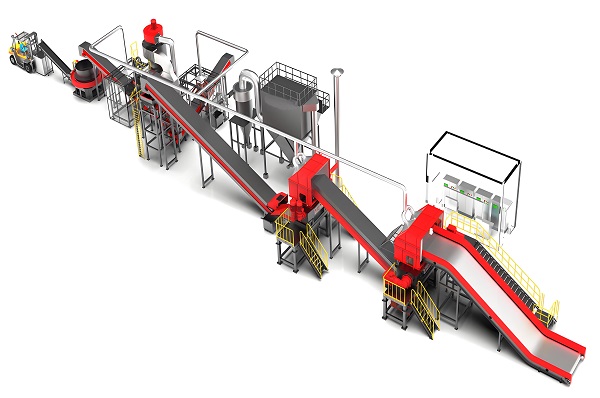

The equipment of this project consists of the third-generation fine shredder, chain conveyor, belt conveyor, magnetic separator, uniform feeder and RDF pellet mill. Through fully automated crushing, sorting and molding processes, industrial solid wastes such as plastic bags, oil paper, waste clothes and other combustible materials are converted into RDF with high calorific value, which are sold to local coal-fired power plants to reduce coal consumption and carbon emissions while gaining considerable economic benefits. The customer said that he is very satisfied with the new fine shredder, which has high efficiency and wide material adaptability.

The client is a domestic company with strong capabilities in industrial solid waste resource disposal. The processing materials mainly consist of combustible materials such as plastic bags, oil paper, and waste clothing, as well as seasonal straw. Through the fully automated crushing and sorting and RDF forming process configured by Zhongcheng, industrial solid waste is converted into high-density, high calorific value RDF fuel, which is then sold to local coal-fired power plants to reduce coal consumption, carbon emissions, optimize air quality, and increase revenue while turning waste into treasure.

The production efficiency of the rod making production line is high: the rod making machine equipment has a fast rod making speed and can complete the compression molding of a large amount of raw materials in a short period of time, improving the overall production efficiency. Wide range of raw materials: The stick making machine is suitable for the compression molding of various biomass raw materials, such as wood, rice husks, peanut shells, plant straw, etc. These raw materials are widely sourced and renewable, which helps reduce dependence on traditional energy sources. Reasonable design: The rod making machine is designed reasonably, with a simple structure and easy operation, reducing the skill requirements for operators.

Save Time! Get A Detailed Quotation Quickly.