Based on the different recycling values of large waste, Zhongcheng Machinery has designed a professional resource utilization system for large waste. Through highly automated processing equipment and intelligent management system, it achieves automatic classification and recycling of various useful resources in large waste. Not only does it increase the value of the product, but it also saves labor and time costs for the enterprise.

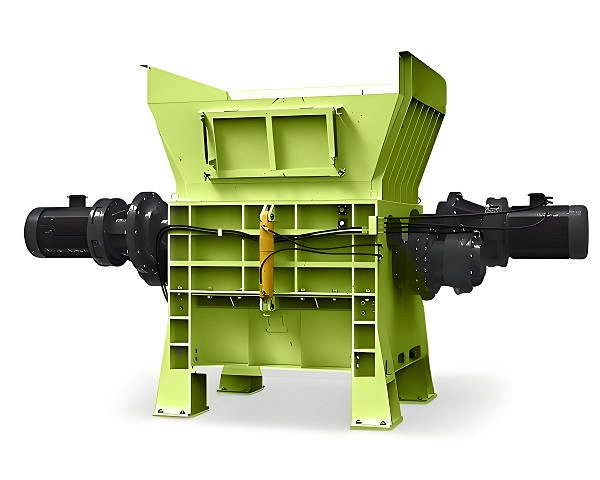

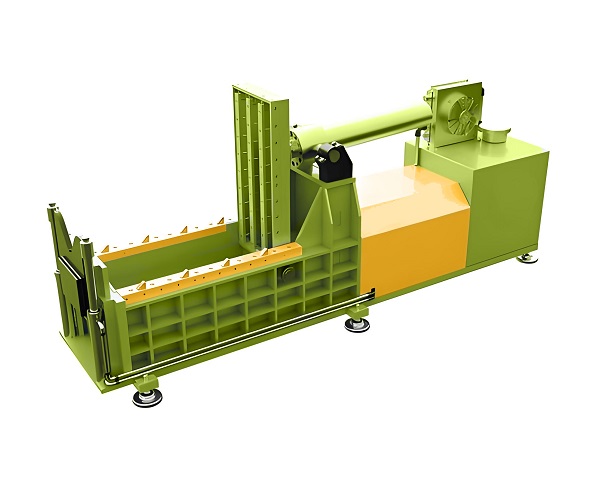

The resource utilization system consists of a metal chain plate conveyor, a specialized shredder for large garbage, a sorting and impurity removal system, a sealed belt output system, a pulse dust removal system, and a GI intelligent control system. The entire production line is automated and collaboratively processed, forming a stable, safe, clean, and environmentally friendly processing loop. This not only effectively reduces energy consumption, labor, and other operating costs, but also significantly prolongs the service life of equipment.

The system can flexibly adjust its configuration according to the final use after processing, achieving the resource utilization of different materials. For example, after separating bamboo and wood, they can be made into wood plastic boards and fiberboards; Iron and springs can be melted back into the furnace; Sponge can be made into recycled cotton, shoe soles, and various decorative items; Plastic, shredded cloth, and leather can be used to produce RDF or SRF as fuel for waste incineration power plants.

The large-scale waste resource utilization solution adopts the "multi-stage crushing+multi-stage sorting" process, which is designed by Jiepu Intelligent Environmental Protection for the comprehensive treatment center of large-scale waste resource utilization. It is a refined resource utilization system for large-scale waste.

The material is fed into the ZCL shredder dedicated for large garbage through a chain plate conveyor for preliminary crushing, and then enters the secondary crusher to be crushed into finer and more uniform particles. Then, the iron metal is removed by a magnetic separator, and the combustible light material is separated from the wood by an air separator. Finally, the combustible light material is processed into RDF fuel rods by an RDF forming machine.

The system is equipped with an automatic control system and dust removal equipment, which can achieve highly automated cleaning operations. Zhongcheng Machinery can also provide an intelligent GI monitoring system for production lines, which can summarize and analyze various operational data at any time to assist enterprises in digital management.

Advantages of the plan:

1. The intelligent GI system can achieve full production line operation monitoring and data analysis, with a high degree of overall automation, which can significantly reduce manual operations and lower operating costs;

2. The "multi-level sorting" system can achieve automatic classification and processing of large garbage, with a high degree of resource utilization, and is more suitable for the processing of mixed large garbage;

3. Adopting the patented products of Jiepu Company, the processing efficiency is high, the particle shape is good, and the finished product quality is more advantageous.

Craftsman's mind creates lean products

Save Time! Get A Detailed Quotation Quickly.