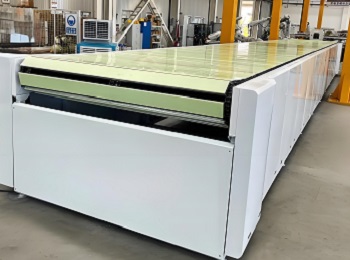

CPC series chain plate conveyor is a kind of conveying equipment that uses 360° circulation bending chain and corresponding chain wheel as traction power, and uses metal plate as the carrier of conveying load. This machine is widely used in various fields because it conveys various goods of different weight through continuous or intermittent movement. Its function is to save labor cost and improve production efficiency.

In addition to the transportation of ordinary materials, the equipment can also meet the transportation requirements of oil resistant, corrosion resistant and other special materials, and is widely used in light industry, electronics, food, pharmacy, machinery, daily chemical industry, solid waste disposal and other industries.

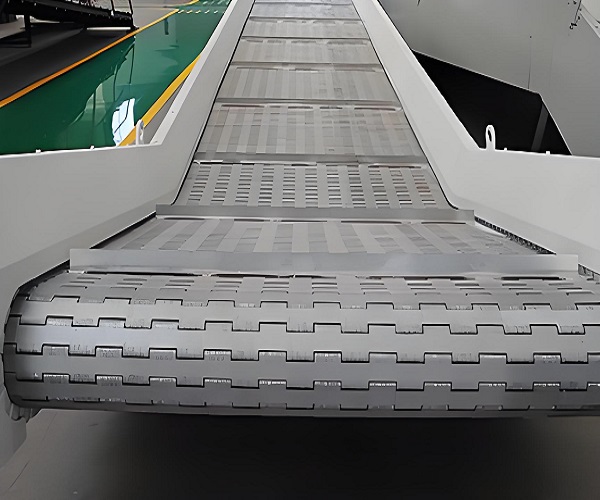

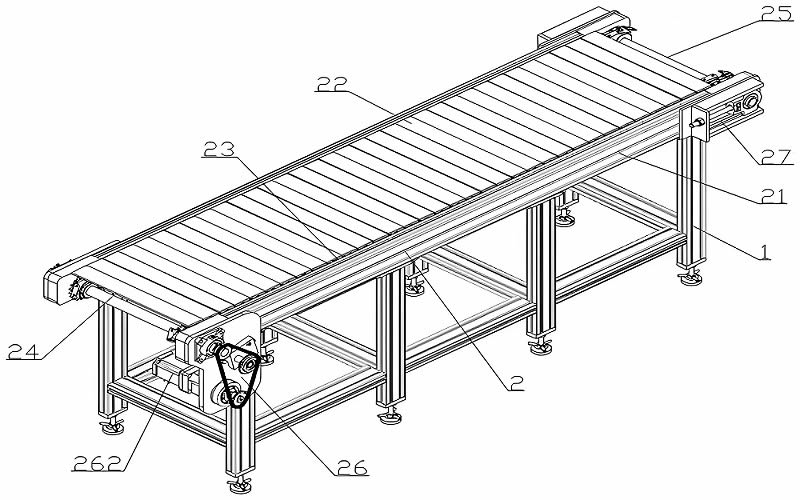

Chain plate conveyor is composed of power unit, transmission shaft, roller, tensioning device, chain wheel, chain, bearing, chain plate, etc. It uses a series of chains fixed on the traction chain to provide traction, and uses metal plate as the carrier to guide materials to be transported along the horizontal or inclined direction.

1. Consider conveying distance and height: Determine the conveying distance of the conveyor and the height that needs to be raised or lowered.

2. Ensure that the structure of the conveyor is sturdy, durable, able to withstand the required load, and easy to maintain and clean.

3. Consider conveying capacity: Ensure that the conveying capacity of the conveyor meets production needs.

4. Consider brand reputation: Choose suppliers with good brand reputation and word-of-mouth.

5.If standard products cannot meet specific needs, customized conveyors can be considered. When customizing, communicate the requirements in detail with the supplier to ensure that the customized product meets the expected requirements.

In summary, choosing a Chain Plate Conveyor requires comprehensive consideration of multiple factors, including requirements, types, materials and structures, performance parameters, and suppliers. By careful evaluation and comparison, the most suitable conveyor can be selected to meet production or logistics needs.

Low strength wear-resistant chain transmission is adopted, and the delivery surface is flat and smooth, with low friction.

Heavy load chain plate, which can meet the requirements of fast transportation of materials with large volume and weight.

The mechanical structure is firm and stable, the quality is safe and reliable, and the service life is long.

Large transportation volume, high stability, convenient operation, strong adaptability, and flexible layout

The Chain Plate Conveyor is mainly composed of power devices (such as motors), transmission shafts, rollers, tightening devices, sprockets, chains, bearings, lubricants, and chain plates. Among them, chains and metal plates are the two main parts for conveying animal materials.

The traction effect of the chain: The Chain Plate Conveyor utilizes a series of chains fixed to the traction chain to provide traction. These chains, driven by the power unit, undergo cyclic reciprocating motion, thereby driving the entire conveyor system to work.

The load-bearing function of metal plates: As a carrier during the conveying process, metal plates are responsible for guiding materials to be conveyed in the direction of the chain's movement (horizontal or inclined). The design of metal plates usually has a certain strength and stiffness to ensure stable load-bearing of materials during transportation.

The combination of sprocket and drum: The sprocket and drum play a crucial role in the transmission and support of the Chain Plate Conveyor. The sprocket meshes with the chain, transmitting power to the chain; And the drum supports the metal plate to keep it running smoothly during the conveying process.

The function of tightening device and lubricant: The tightening device is used to adjust the tension of the chain to ensure that the chain maintains appropriate tension during transmission. Lubricants are used to reduce friction and wear between components such as chains, sprockets, and rollers, improving the operational efficiency and service life of the entire conveyor system.

| Model | HB50 | HB60 | HB70 | HB80 | HB100 | ||

| Chain bucket (plate) width (mm) | 500 | 600 | 700 | 800 | 1000 | ||

| Conveyor speed(m/min) | 7~14 | ||||||

| Transportation capacity | Bucket(m2/h) | 15~25 | 20~35 | 30~40 | 40~50 | 50~70 | |

| Plate(mm) | 15~20 | 20~30 | 30~35 | 40~45 | 45~55 | ||

| Conveying distanceF(m) | Generally ≤ 40, larger than 70 | ||||||

| Transporting materials with larger particle sizes | Bucket(mm) | 80 | 100 | 140 | 160 | 200 | |

| Plate(mm) | 120 | 160 | 200 | 240 | 300 | ||

| Allow upward tilt angle(°) | Bucket | ≤45° | |||||

| Plate | ≤15° | ||||||

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.