Waste Management Machine .Waste Sorting Machines (also known as MSW sorting plants) are advanced automated systems designed to efficiently separate mixed waste streams into specific categories. These include ferrous metals, non-ferrous metals, various plastics, paper, cardboard, glass, wood, and more.

The sorted materials are then directed towards optimal recycling and recovery processes:

Inorganic inert waste is repurposed for producing construction and building materials.

High-calorific non-recyclable waste is converted into Solid Recovered Fuel (SRF) and Refuse-Derived Fuel (RDF) pellets.

Organic food waste is processed through anaerobic digestion or composting, supporting renewable energy generation and soil enrichment.

This integrated approach enhances landfill diversion, promotes a circular economy, and maximizes resource recovery from municipal solid waste.

What is Municipal Solid Waste Sorting Machine?

MSW sorting machine is a special equipment that uses sorting technology to realize automatic and efficient sorting and collection of garbage and waste by mechanized and professional means. Garbage and waste can be classified into two categories: recyclables and non-recyclables, among which recyclables mainly include: various types of plastics, various metals, glass, paper, combustible mixtures, organic mixtures, building in-organics, etc. All the recyclables can be further processed to useful resources.

How Does Municipal Solid Waste Sorting Machine Work?

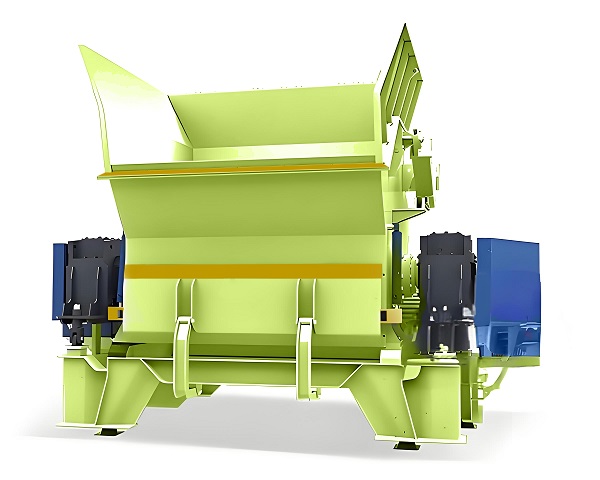

An efficient Municipal Solid Waste (MSW) sorting plant employs a combination of mechanical and automated processes to separate and recover valuable resources from mixed garbage.

Firstly, you need to plan the site to install 1 domestic waste sorting line. The minimum planned area of a production line is about 20*75=1500m.When you have all the facilities in the workshop, garbage collection trucks and manpower ready, you can start sorting garbage.

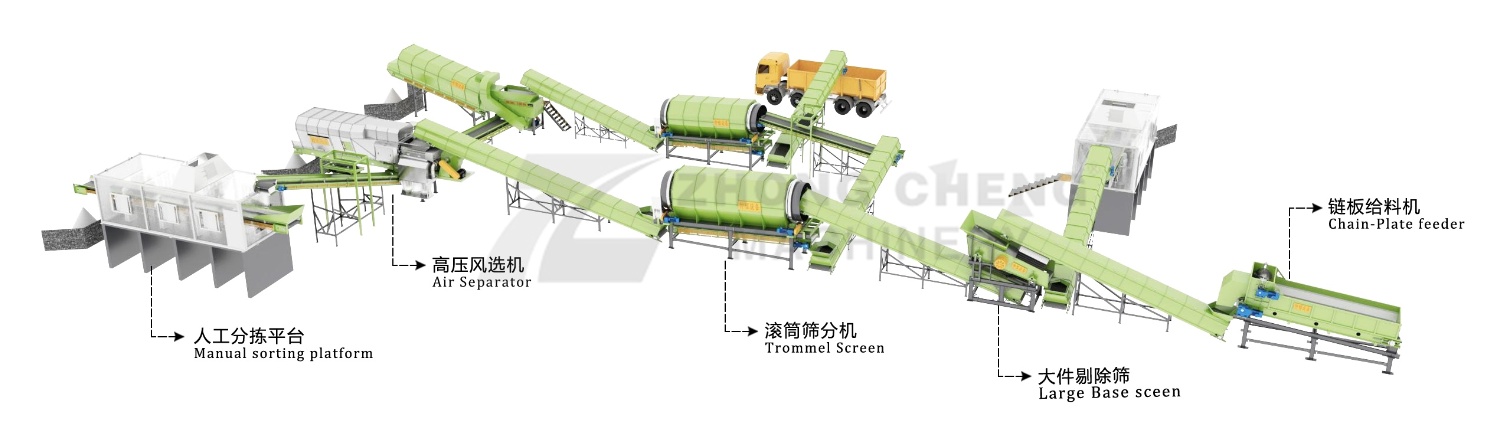

1. Waste Delivery and Initial Feeding

Garbage collection trucks transport waste to the processing facility and unload it into a hopper. A plate feeder steadily supplies the material onto a conveyor system, ensuring a consistent flow into the preprocessing stage.

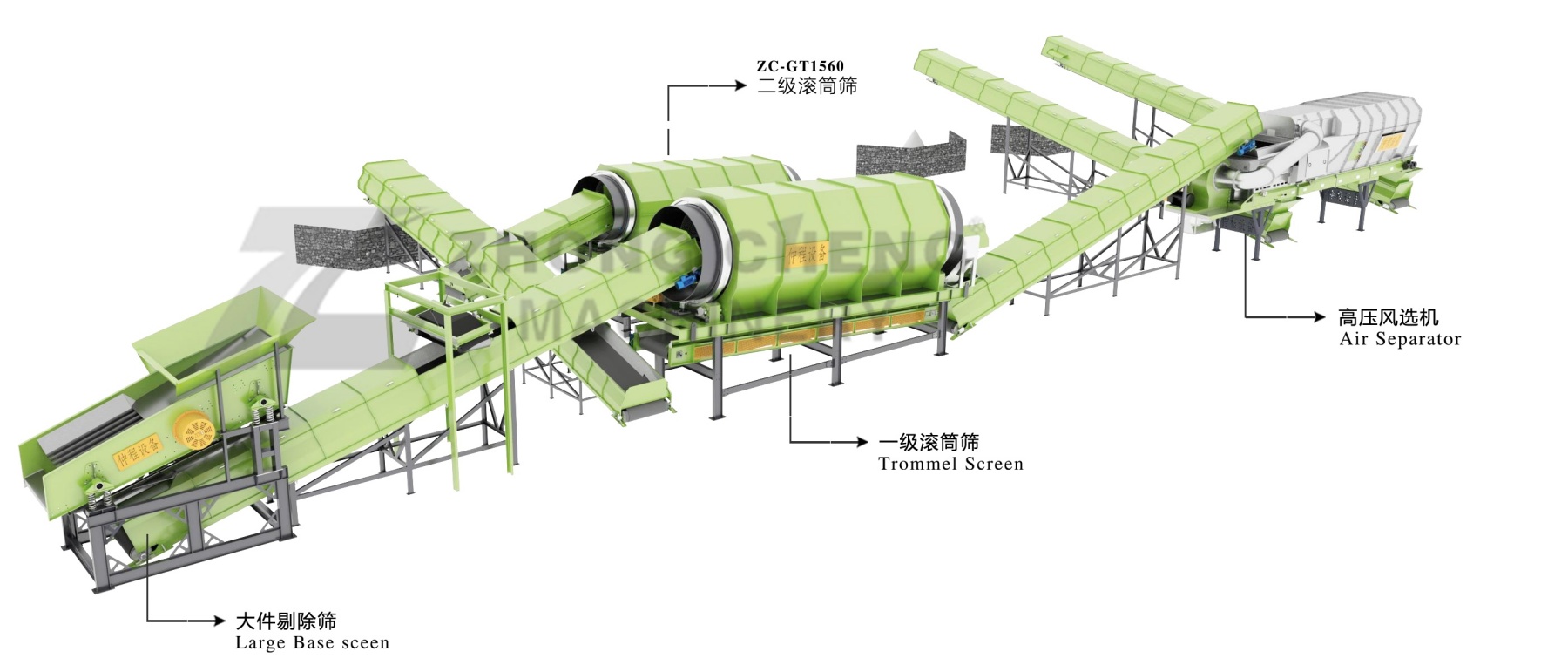

2. Large Item Pre-Screening

The waste first enters a large-item pre-screening machine. This critical step separates oversized materials before further processing.

Oversized materials (screen-overflow) are sent to a manual sorting platform, where workers retrieve recyclables such as cardboard, plastic bottles, and other large reusable items.

Small-sized materials (screen-underflow) proceed directly to the trommel screen without crushing, preserving material integrity and minimizing damage to recoverables.

3. Trommel Screening

The pre-screened material enters a trommel screen—a rotating drum with sieve plates (typically 30–60 mm apertures).

Small particles (≤ sieve size) fall through as undersize, rich in organic matter.

Large particles (> sieve size) move forward as oversize for further recovery.

4. Magnetic Metal Recovery

Both undersize and oversize streams pass under magnetic separators to extract ferrous metals (e.g., iron and steel), which are collected for recycling.

5. Organic Waste Processing

The undersize fraction from the trommel—primarily organic material—is gathered and transported for composting or anaerobic digestion, converting waste into fertilizer or biogas.

6. Air Classification

The non-magnetic oversize materials are conveyed to an air separator. Using aerodynamic properties, this system divides materials into:

Light materials: plastics, films, and paper;

Heavy materials: dense inert substances like glass, rocks, and ceramics;

Semi-heavy materials: mix of organics and combustibles.

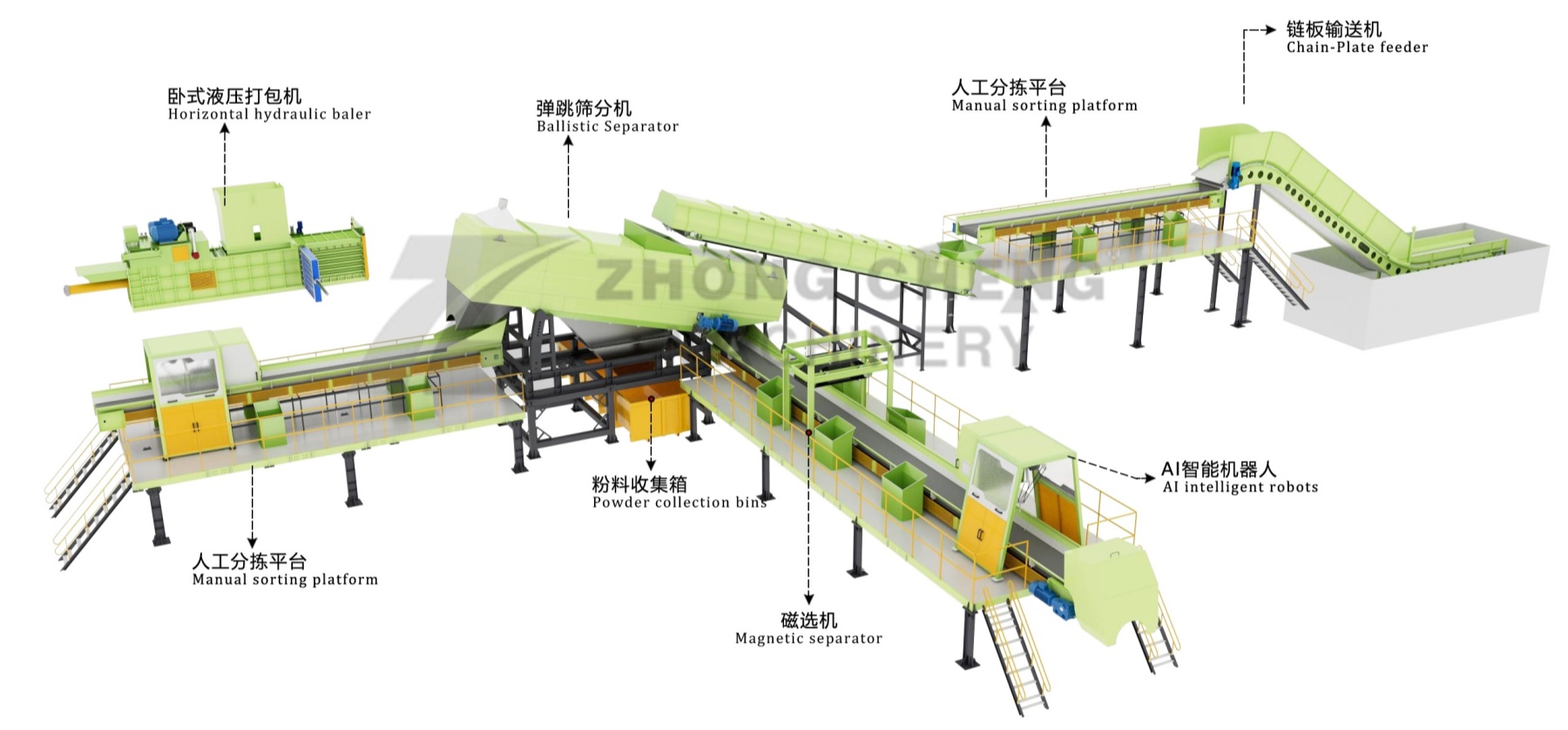

7. Final Sorting and Resource Recovery

Heavy materials undergo manual sorting to recover recyclables like rubber and glass. The remainder can be use as construction aggregate or sent to inert landfills.

Semi-heavy materials, with high calorific value, are ideal for waste-to-energy incineration after manual recovery of remaining recyclables.

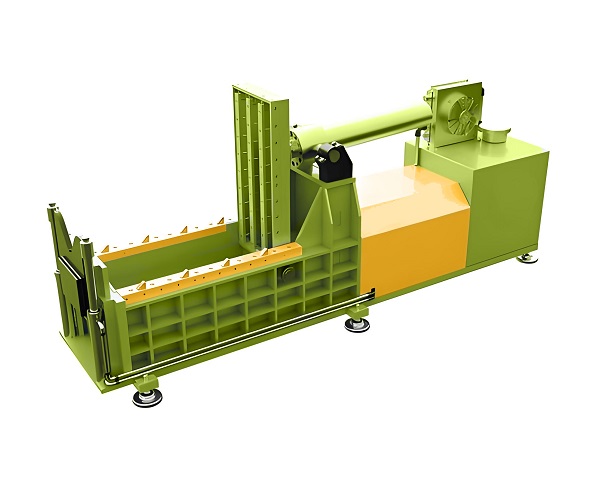

Light materials (mainly plastics and paper) are purified on a manual picking platform, baled, and sent for recycling. Plastic films can be washed and pelletized for new products.

8. Environmental Management

Leachate generated during process is collected, treated, and reused for cleaning or irrigation.

Exhaust gases are captured and purified before release, ensuring compliance with environmental standards.

Benefits of Using Waste Sorting Machines for Municipal Solid Waste (MSW)

Waste sorting machines offer numerous advantages for processing municipal solid waste, enabling smarter, safer, and more sustainable waste management.

Environmental Benefits

Landfill Reduction: Diverts over 80% of waste from landfills, extending their lifespan and reducing soil and groundwater contamination.

Lower Carbon Emissions: Captures methane from organic waste via anaerobic digestion and reduces greenhouse gases through recycling, which saves energy compared to virgin material production.

Resource Conservation: Recovers high-purity materials, minimizing the need for virgin resource extraction and supporting a circular economy.

Economic Benefits

New Revenue Streams: Produces high-market-value materials (e.g., metals, plastics) and converts non-recyclable waste into energy sources like SRF/RDF pellets.

Reduced Operating Costs: Lowers expenses related to manual sorting, transportation, and long-term landfill management.

Data-Informed Decisions: Delivers detailed waste analytics to optimize recycling programs, reduce contamination, and improve policy-making.

Safety and Social Benefits

Improved Worker Safety: Reduces human exposure to hazardous conditions through automation of dangerous tasks.

Enhanced Public Health: Promotes cleaner urban environments by reducing uncontrolled dumping and pollution.

Green Job Creation: Generates employment opportunities in tech-driven roles including system operation, maintenance, and resource management.

Material Recovery and valorization

Organic Waste: Treated through anaerobic digestion for biogas production or composting for agricultural use.

Inorganic Waste: Repurposed into construction materials, decreasing the demand for new minerals.

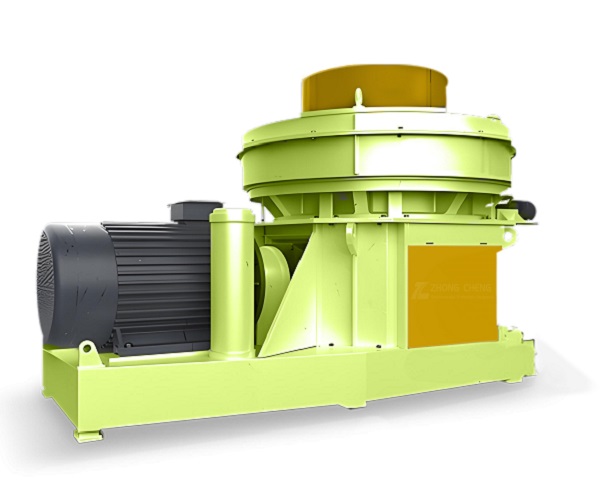

High-Calorific Waste: Processed into Solid Recovered Fuel (SRF) and Refuse-Derived Fuel (RDF) pellets, offering a sustainable alternative to fossil fuels.

What is Sorting in Waste Management and Where Does Sorted Waste Go?

Sorting is the foundational process in modern waste management that involves separating mixed waste into distinct categories—such as plastics, metals, paper, organic materials, and glass—for recycling, composting, energy recovery, or safe disposal. It serves as the essential first step in converting waste into reusable resources and advancing the circular economy.

Effective waste sorting can be performed both at the source (by households and businesses) and through mechanized systems. Advanced waste sorting machines—equipped with sensors, artificial intelligence, and automated separation technologies—significantly enhance the speed, accuracy, and efficiency of material recovery, minimizing the volume of waste destined for landfills.

Why Is Waste Sorting Important?

Proper waste sorting helps:

Increase recycling rates and material purity

Reduce environmental pollution and greenhouse gas emissions

Conserve natural resources by channeling materials back into production cycles

Facilitate the production of refuse-derived fuel (RDF) and compost

Support compliance with environmental regulations and sustainability targets

Where Does the Sorted Waste Go?

After sorting, materials follow specialized pathways to ensure optimal resource recovery:

Plastics:

Sorted plastics can be processed through pyrolysis to produce plastic oil and carbon black, which can further be refined into diesel. Alternatively, they can be pelletized into reusable plastic pellets.

Metals:

Extracted metals are sent for smelting and refinement to produce new steel and other metal products.

Organic Waste:

Organic materials are directed to anaerobic digestion systems to produce biogas, or composed into organic fertilizers for agricultural use.

Biomass Waste (e.g., straw, wood, sewage sludge):

These materials can be carbonized in a charcoal making machine to produce biochar for energy or agricultural applications.

Paper Waste:

Paper is pulped and molded into paper trays, egg cartons, or other recycled products.

Bricks and Stones:

Inert materials like brickbats and stones are compacted or briquetted for reuse in construction.

Kitchen Waste:

Food scraps are transformed into organic fertilizer or fed into biogas systems for energy recovery.

Combustibles:

Non-recyclable high-calorific waste is converted into refuse-derived fuel (RDF) or solid recovered fuel (SRF) for use in cement kilns or power plants.

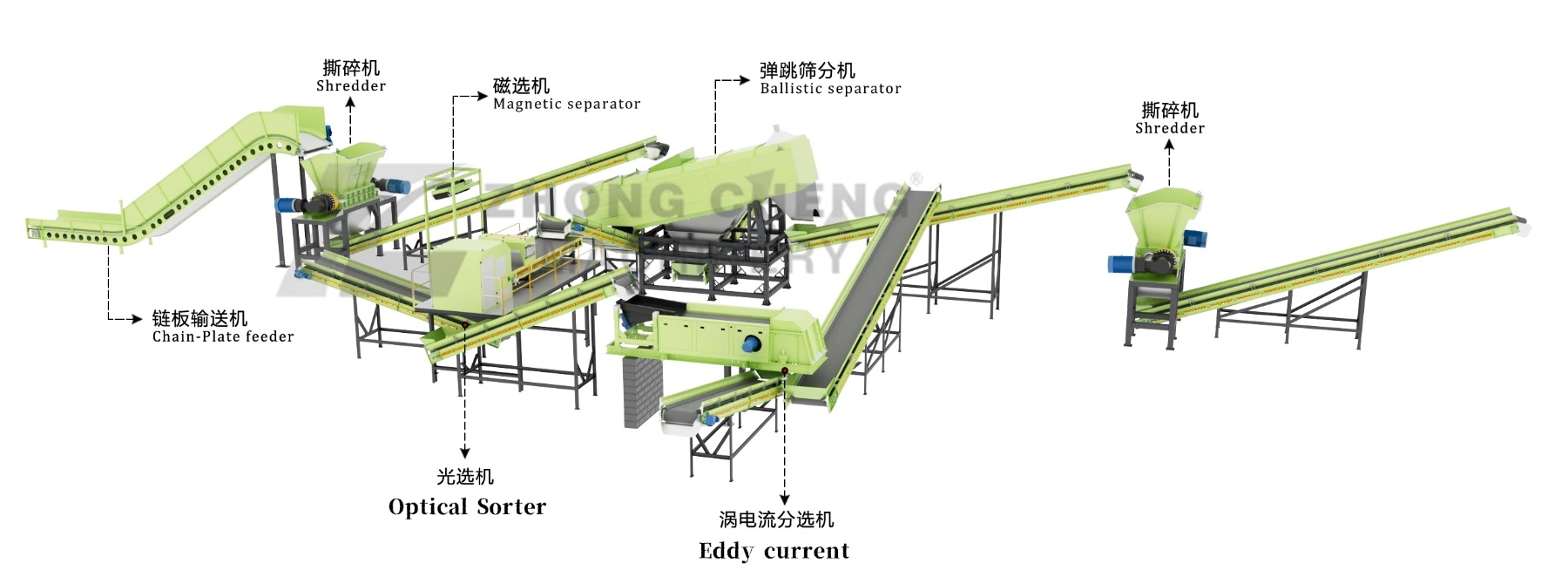

The Role of Advanced Sorting Technologies

Modern Material Recovery Facilities (MRFs) deploy AI, optical sensors, near-infrared (NIR) technology, eddy current systems, and ballistic separators to achieve high-purity material streams. These technologies improve recovery rates, lower operating costs, and enhance the economic viability of recycling operations.

Waste sorting machines are engineered to transform mixed waste into valuable sorted materials through automated, intelligent, and high-capacity processes. Key features of modern waste sorting systems include:

High Automation & Throughput: Fully automated operation allows continuous processing of large waste volumes, significantly reducing manual labor and operational costs.

Advanced Sensor Technology: Equipped with near-infrared (NIR) sensors, optical sorters, and AI-powered vision systems to accurately identify and separate plastics, metals, paper, and other materials.

Robust Material Handling: Includes vibrating screens, trommels, ballistic separators, and magnetic/eddy current systems for efficient size-based and material-based classification.

User-Friendly HMI & Data Analytics: Real-time monitoring and data recording enable performance tracking, maintenance alerts, and process optimization for higher recovery rates.

Durability & Safety Design: Built with wear-resistant materials, dust-proof structures, and safety interlocks to ensure long-term reliability and operator protection.

Environmentally Optimized: Supports zero-waste goals by improving recycling purity, reducing landfill reliance, and enabling circular economy pathways.

Ideal for MRFs, recycling centers, and municipal solid waste plants, our sorting machines maximize recovery efficiency, reduce contamination, and turn waste into resource opportunities.Waste Management Machines.

Craftsman's mind creates lean products

Save Time! Get A Detailed Quotation Quickly.