ZCS series pre-shredder is a high-torque waste pretreatment equipment, used in the first stage of the waste treatment process, suitable for pre-shredding municipal solid waste (MSW), bulky waste, C&D waste, etc. The shredder uses the principle of shearing and tearing to realize shredding, which can shred extremely coarse materials forcefully and prevent the accumulation of raw materials.

Large-scale waste treatment applications face many challenges. For example, the large-scale processing requirements put huge pressure on subsequent treatment equipment, and the wide range of changes in electrical load caused by different types and sizes of waste, etc., which will cause huge uncertainties to the entire system. The addition of a pre-shredder to the disposal system helps to reduce and disassemble the material before it is sent to the main shredder, reducing risks and at the same time homogenizing the feed. Pre-shredders are widely used in projects such as car shell shredding and large-scale obsolete waste disposal.

The pre-shredder is installed in front of the main shredder to help reduce and break up the material before it is fed into the main shredder. This helps to extend the life of the main shredder cutters and prevents non-shreddable and flammable materials from entering, while reducing peak power loads and keeping the line running smoothly. The pre-shredder also homogenises the feed and helps to control the feed rate to the main shredder, thereby increasing throughput and reducing unit processing costs.

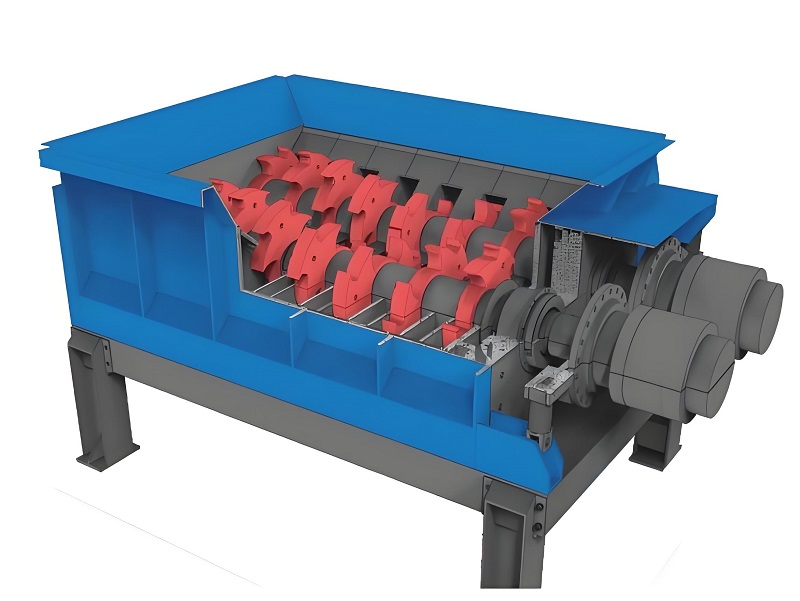

The ZCS pre-shredder uses a low speed, high torque double hydraulic motor to drive the cutter rolls directly. It uses the interaction between the cutters and the middle comb plate to shear, tear and pull the material, and is mostly used as the first step in the shredding process of various solid wastes.

Clarify the types of materials that need to be pre shredded, such as plastic, paper, metal, food waste, etc. Different materials have different requirements for the design and configuration of shredders.

The original size and shape of the material will affect the feeding port size, blade design, and shredding effect of the shredder.

Choose the appropriate pre shredder model and specifications based on your production or processing capacity requirements. The processing ability should match your actual needs, avoiding resource waste or low efficiency caused by being too large or too small.

The blade is a key component of the pre shredder, and its material directly affects the shredding effect and durability. Choose blade materials that are wear-resistant, corrosion-resistant, and high-strength.

The size and shape of the shredding chamber should be able to accommodate sufficient materials and allow the blades to rotate freely to achieve the best shredding effect.

The motor power directly affects the processing capacity and efficiency of the pre shredder. Select the appropriate motor power based on the processing material and required processing capacity.

The hydraulic system is equipped with high quality hydraulic pumps and valves, with strong power output, ensuring efficient and stable operation of the hydraulic system.

Intelligent monitoring system can realize intelligent data analysis, visualization of production process, timely abnormal alarm and safety intelligence.

The hydraulic motor is directly driven by a low-speed, high-torque hydraulic motor, which is directly connected to the cutter shaft of the shredder, with high transmission efficiency.

Improve after-sales service system, supply of accessories, high cost-effectiveness, easy operation, and durability.

The working principle of Pre-Shredder is mainly to use the mechanical principles of shearing, tearing, and crushing to cut waste items into smaller pieces. The basic working steps of a shredder include material entry, cutting and tearing, crushing and compression, and fragment discharge. The shredder usually contains a set of rotating cutting blades or gears inside, which cooperate with each other to apply shear and tearing forces to the incoming material. During the cutting and tearing process, the material is broken into smaller fragments, which may be further compressed and crushed to achieve the desired particle size and density. Finally, the processed fragments are discharged through the outlet of the shredder. Depending on the type and purpose of the processed material, the fragments may be collected in containers or directly transported to other equipment for further processing.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| ZCS12 | 10-30 | 100-400 | 3500×1900×3100 |

| ZCS16 | 20-40 | 3800×2200×3200 | |

| ZCS18 | 40-60 | 4800×2400×3300 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.