The waste trommel screen machine is a device used for processing garbage and recyclables. Its main function is to separate the mixed garbage and recyclables for subsequent processing and utilization.

Trommel Screen is a screening equipment widely used in industries such as garbage sorting, mining, coal, electricity, and building materials. It screens materials through a rotating sieve, separating materials of different particle sizes to meet the requirements of the production process. The Trommel Screen has the characteristics of simple structure, easy operation, low maintenance cost, high screening efficiency, strong adaptability, and low noise. The cylinder is generally divided into several sections, and the sieve holes are arranged from small to large, with the same aperture in each section. During work, materials enter the Trommel Screen and are screened and separated by the rotation and vibration of the screen mesh. The Trommel Screen not only improves the quality of materials, but also provides strong support for the optimization and progress of production processes.

Trommel Screens are widely used in multiple industries, including:

Mining industry: used for preliminary screening of ores, classifying ores according to different particle sizes to provide suitable raw materials for subsequent processing.

Coal industry: During the coal washing process, Trommel Screens can effectively separate impurities such as coal gangue and coal slurry, improving the purity and utilization rate of coal.

Power industry: In coal-fired power plants, Trommel Screens can be used for pre-treatment of fuel coal to ensure uniform coal particle size and improve combustion efficiency.

Building materials industry: In the production process of building materials, Trommel Screens can be used to screen raw materials such as sand and gravel, ensuring the stability and consistency of product quality.

Chemical industry: In the screening process of chemical raw materials, Trommel Screens can be used to separate materials of different particle sizes to meet the requirements of production processes.

Environmental protection industry: Roller screens are also used in fields such as garbage treatment and sewage treatment, which can be used to separate garbage or particulate matter of different sizes, achieving effective recycling and utilization of resources.

In short, Trommel Screens play an important role in multiple industries due to their high efficiency, flexibility, and strong adaptability.

1.Pay attention to screening requirements: clarify the type of material to be processed (such as humidity, viscosity, particle size, etc.), expected processing capacity (how many tons of material to process per hour), and expected screening accuracy (ability to separate different particle sizes). These requirements will directly affect the selection of drum screens.

2. Pay attention to materials and durability: The materials of the drum and screen should have sufficient strength and corrosion resistance to ensure long-term stable operation. Choosing a reputable and experienced manufacturer can provide more reliable product quality and after-sales service.

3. Consider cost-effectiveness: evaluate the overall cost of ownership of the equipment based on its performance, durability, and operating costs. Although high-quality equipment may require higher initial investment, it is more cost-effective in the long run.

4. On site inspection and trial operation: Personally visit the manufacturer to inspect the production process and understand the strength of the enterprise. And verify the performance and applicability of the equipment through actual screening tests.

5. Understanding user feedback and case studies: Understanding the user experience and feedback of other users, studying the performance of drum screens in similar application scenarios, can help make more informed choices. In summary, when choosing a drum screen, multiple aspects need to be considered comprehensively to ensure that the selected equipment can meet production needs and bring good economic benefits.

In summary, when choosing a drum screen, multiple aspects need to be considered comprehensively to ensure that the selected equipment can meet production needs and bring good economic benefits.

Screen long life span. Screen seive is made with strong strength, good abrasion resistance and high screening efficiency.

Designed to fit your operation.Trommel screen can be customized to meet different capacity and working site.

Free from pollution.Fully enclosed structure,no dust pollution,improve working conditions for operators as well.

Variable application range. Compost,chemical,coal,plastic,recycling,metallurgy,mineral screening etc.

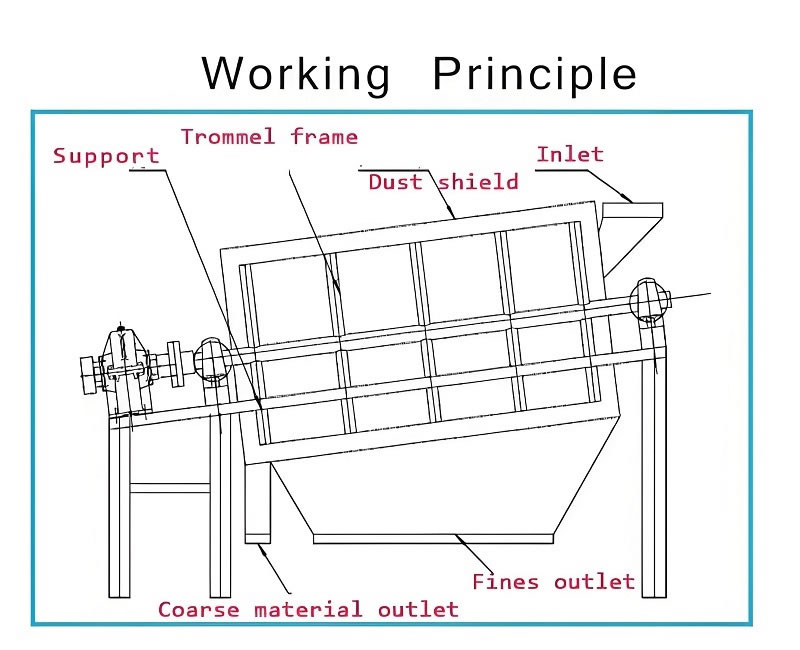

Trommel Screen is a commonly used screening equipment used for grading and separating materials. Its working principle is based on the rotation of the drum and the movement of materials on the surface of the drum.

The working process of the Trommel Screen is as follows:

1. Material feeding: The material enters the interior of the Trommel Screen through the feeding port.

2. Screening process: The drum begins to rotate, and the material is subjected to centrifugal force on the surface of the drum while moving along the length direction of the drum. Smaller particles will pass through the sieve or sieve plate, while larger particles are blocked on the screen.

3. Grading and Separation: Materials are classified into different size grades based on the size of the sieve or sieve plate. Smaller particles pass through sieve holes or sieve plates, while larger particles are retained on the surface of the drum.

4. Discharge: After screening, materials of different sizes move forward along the length direction of the drum and are discharged from the Trommel Screen through the discharge port.

The Trommel Screen is mainly composed of a screen box, a motor, a reducer, a drum, and a bracket. The material enters the screening box from the feeding port, and the drum begins to rotate. The material continuously flips and rolls inside the drum, thus achieving the screening of the material.

The material continuously rolls and scatters inside the cylinder as it rotates, and gradually separates through the sieve holes under the action of gravity and centrifugal force. The size of the sieve holes can be adjusted according to actual needs to meet the screening requirements of materials with different particle sizes. Larger particles are filtered out by the mesh inside the drum, while smaller particles fall through the mesh into the discharge outlet below.

The screen mesh of a Trommel Screen is generally composed of multiple layers of screens with different aperture sizes to achieve separation of materials with different particle sizes. Meanwhile, the Trommel Screen can also adjust the speed and inclination angle of the drum as needed to meet the screening requirements of different materials.

| Model | Drum size(mm) | Yield(t/h) | Motor power(KW) | Appearance size(mm) | |

| diameter | length | ||||

| AG6*30 | φ800 | 3000 | 0.5-1 | 1.5 | 4000*1000*1800 |

| AG8*40 | Φ600 | 4000 | 1-2 | 1.5 | 5000*1200*1800 |

| AG10*30 | Φ1000 | 3000 | 1-3 | 2.2 | 5000*1400*2000 |

| AG12*45 | Φ1200 | 4500 | 3-5 | 3 | 5700*1600*2400 |

| AG15*50 | Φ1500 | 5000 | 5-7 | 5.5 | 6800*1900*2800 |

| AG15*65 | Φ1500 | 6500 | 16-24 | 7.5 | 8300*1900*2800 |

| AG16*60 | Φ1600 | 6000 | 16-24 | 7.5 | 7300*2000*3000 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.