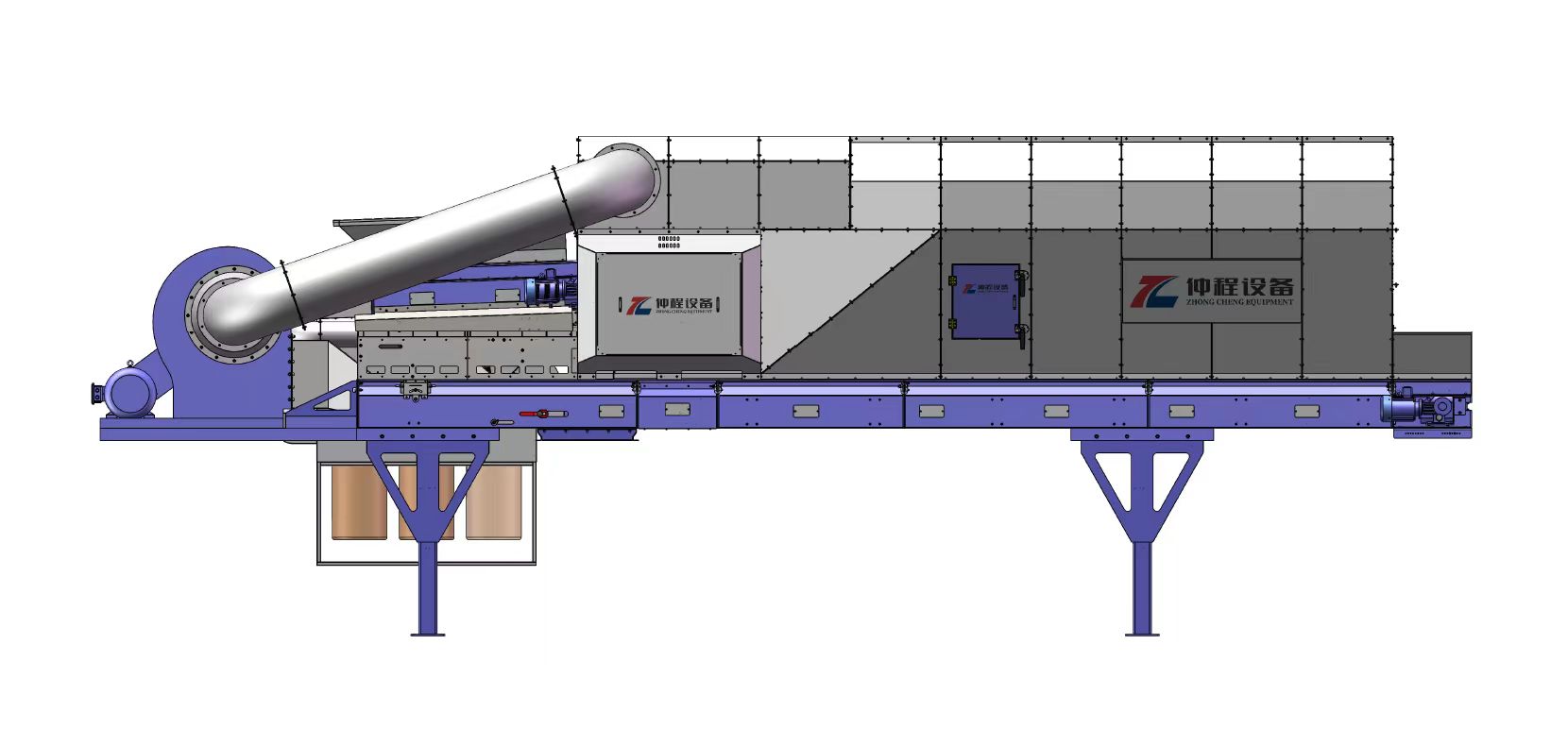

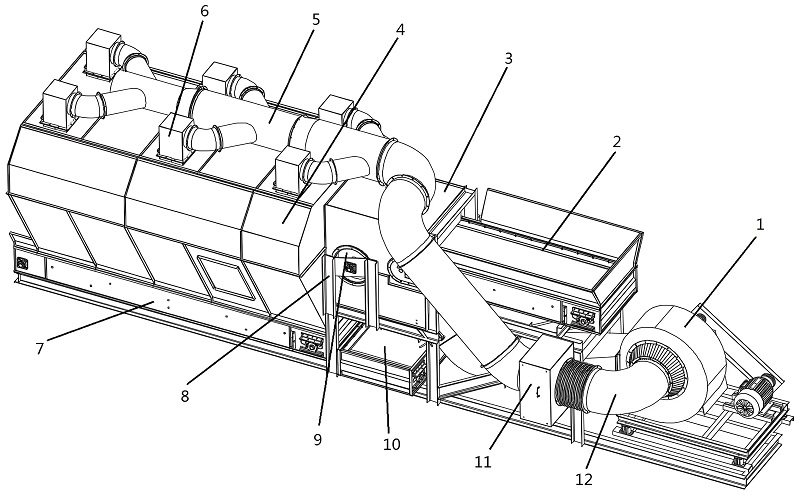

ZFX series wind sifter, also known as drum density sorter, consists of centrifugal fan, separation unit of rotating drum, belt machine and settling chamber. It uses the principle that materials are light and heavy and wind resistance is different to drive the materials with the same size of wind to achieve the purpose of easy automatic classification of materials.

ZFX series wind sifter is mostly suitable for pre-treatment processing of SRF/RDF fuel for domestic waste, landfill obsolete waste, industrial solid waste, paper waste, textile waste, leather waste, rag waste, etc. Wind sorting machine according to the principle of aerodynamics, controlled airflow for sorting media, to sort materials according to the density and size, airflow can let lighter materials (such as paper, plastic bags, film, etc.) upward away or horizontal direction to a farther place, while heavy materials due to the rising airflow cannot support them and land, or due to inertia in the horizontal direction thrown to a closer distance. Thus, the wind sorting process is based on the law of settling of materials in the air, thus achieving sorting purposes.

The waste sorting wind screening machine is mainly based on the principle of aerodynamics. Through high-speed rotation and wind force, it separates the lightweight components (such as paper, plastic, etc.) from the heavy components (such as bricks, concrete, etc.) in the garbage in a reasonable manner. The machine consists of key components such as a frame, motor, reducer, screen, and fan. During operation, decoration waste is sent into the machine, and through high-speed rotation and wind blowing, light components are carried away by the wind force, while heavy components settle on the screen, achieving accurate classification.

The host is controlled by frequency converter, and the wind speed is flexible.

Modular design is adopted for convenient maintenance.

The separation purity is high, which is easy to be further processed in the later process.

Less wearing parts and long service life.

High strength materials are used, manufacturing processes are exquisite, equipment runs smoothly, and is durable.

Design machines based on customer requirements, actual site conditions, and screening needs.

Strong power and good screening effect.

High quality materials, rational design, and precision manufacturing create high-quality products.

Wind sorting is a process that uses air as a sorting medium to separate selected materials according to density and particle size under the action of airflow and mechanical vibration. The basic method of using air as a sorting medium for sorting is to feed the raw materials onto a tilted, fixed or movable porous surface, and use intermittent or continuous upward airflow to push the particle group to suspend and promote stratification according to density differences, or sort according to density (particle size) in vertical or horizontal airflow, such as settling boxes. According to the airflow and the direction of equipment movement, wind sorting can still be divided into processes such as jigs, shakers, and chutes, but the sorting process is very different from that in aqueous media.

The gas pressure required for wind powered jigs and wind powered shakers ranges from 1.5 to 3 kPa. The airflow velocity is equal to the interference settling velocity of the particle swarm. At this point, particles with low free settling velocity are suspended in the upper layer, and the solid volume fraction is relatively small; Particles with high settling velocities are suspended in the lower layer and have a larger solid volume fraction. Among the selected ores, high-density minerals have a higher average settling velocity and are therefore enriched in the bottom layer. The increase in suspension density here also has a certain effect on the exclusion of low-density minerals.

The uniform distribution of airflow velocity on the sorting surface has a significant impact on the accuracy of sorting. The moisture content of raw materials also has a significant impact on the operation. When the moisture content exceeds 4% -5%, particle bonding occurs, and the sorting efficiency and equipment processing capacity sharply decrease.

| Model | Power(kW) | Working Width(mm) | Capacity(m³/h) | Material Particle Size(mm) |

| ZFX800 | 22-37 | 800 | 20-30 | 40-400 |

| ZFX1000 | 22-45 | 1000 | 25-35 | |

| ZFX1200 | 30-55 | 1200 | 35-45 | |

| ZFX1400 | 37-65 | 1400 | 50-60 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.