Mobile heavy hammer crusher is a highly efficient crushing equipment. It has the characteristics of large crushing force, reliable operation, high yield and flexible configuration. It is suitable for crushing a variety of materials. Mobile heavy hammer crusher is a highly efficient, flexible and reliable crushing equipment. It is widely used in environmental protection, construction, mining, roads, railways, water conservancy and other engineering fields.

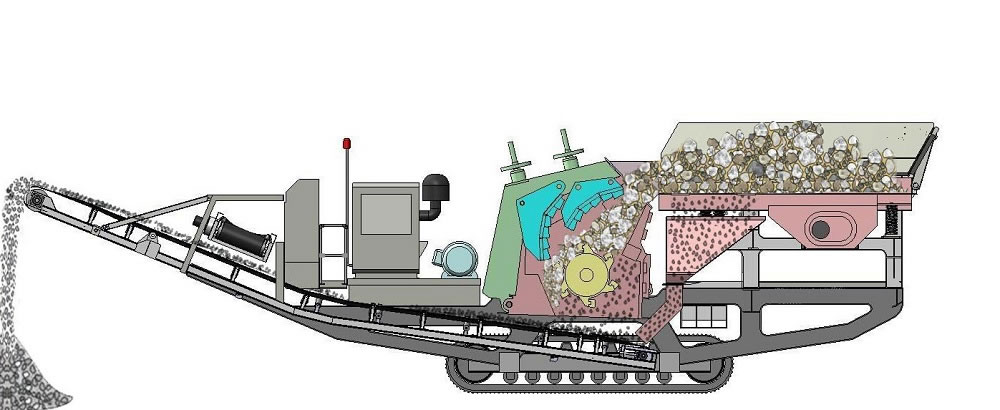

The mobile hammer crusher is an advanced crushing equipment that integrates feeding, crushing, screening and conveying. It combines the advantages of traditional hammer crushers and mobile crushing stations to form a unique operating mode.

The equipment adopts the advanced hammer crushing principle, and uses the high-speed rotating hammer to hit, impact, shear and grind the material to achieve the purpose of crushing. Its crushing chamber is reasonably designed, the material is crushed multiple times in the chamber, the discharge particle size is uniform, and the crushing efficiency is high.

The mobile hammer crusher has high mobility and flexibility, and can be transferred to the work site anytime and anywhere without geographical restrictions. At the same time, the equipment has a compact structure, small footprint, easy installation, and easy maintenance and maintenance.

The mobile hammer crusher is also equipped with an advanced screening system, which can screen the crushed material to obtain products of different particle sizes to meet the different needs of users. At the same time, the equipment also has good environmental performance, low noise, less dust, and less pollution to the environment.

Mobile hammer crusher is a kind of efficient, flexible and environmentally friendly crushing equipment. It is widely used in mining, construction, highway, railway and other fields, providing strong support for users' production.

When choosing a mobile heavy-duty crushing vehicle, multiple factors need to be considered to ensure that the selected equipment can meet actual work needs and has good cost-effectiveness. Here are some key selection points:

1.Firstly, determine the required processing capacity, which is the amount of material that needs to be crushed per hour. The processing capacity of mobile crushing trucks of different models and specifications varies greatly, ranging from tens to hundreds of tons. Material type: Understand the types of materials that need to be crushed, such as ore, construction waste, concrete blocks, etc. Different materials have different requirements for crushers, and suitable crushing methods and models need to be selected.

2. Consider the environment in which the crushing vehicle will operate, such as whether frequent movement is required, site size, road conditions, etc. This will affect the requirements for equipment mobility, adaptability, and stability.

3. Choose equipment with high crushing efficiency and low energy consumption to improve production efficiency and reduce operating costs.

4. Consider the wear resistance of broken components and choose equipment made of high-quality wear-resistant materials to extend their service life and reduce maintenance costs.

5. Evaluate the flexibility of the equipment, including transition speed, installation and debugging convenience, etc. Mobile crushing vehicles should have good maneuverability and adaptability to quickly transition between different sites and put into production.

The one-stop processing mode of this equipment almost includes all the functions of traditional sand yard equipment.

When designing this machine, the concept of promoting environmental protection in the current era was taken into consideration. Therefore, the structural design of this machine is exquisite, with compact connections between various components, low dust and noise during operation, and meets current environmental production standards.

This machine adopts a front traction walking method, which is very convenient to enter and exit the production site. The production process occupies a small area and can adapt to the needs of users to quickly transfer production sites at any time.

The transition is more flexible, with a high degree of intelligence, simple operation, exquisite structural design, compact connection between various components, and high work efficiency.

The working principle of a heavy hammer crusher mainly includes the following points:

1. Material addition method: The crushed material must be evenly added and distributed throughout the entire length of the rotor working part to prevent sudden increase in motor load.

2. Inspection and maintenance of screening strips: It is necessary to regularly check the condition of the screening strips. If there is any blockage, it should be removed immediately to ensure the normal operation of the crusher.

3. Bearing temperature monitoring: Under normal operating conditions, the temperature rise of the bearing should be within the range of 35 ° C, and the maximum temperature should not exceed 70 ° C. If the temperature exceeds 70 ° C, the vehicle should be stopped immediately, and the cause should be identified and eliminated.

4. Parking operation: The feeding work should be stopped before parking, and the motor can only be turned off after the materials in the crushing chamber are completely crushed.

5. Maintenance and adjustment: including timely replacement of the elastic sleeve on the coupling if any damage is found, and adjustment of product particle size can be achieved by changing the sieve strip style or adjusting the sieve strip gap.

| Item | ZMHC1308 | ZMHC1510 | ZMHC1512 |

| Transportation Length(mm) | 14000 | 16000 | 16000 |

| Transportation Width(mm) | 3100 | 3100 | 3100 |

| Transportation Height(mm) | 4300 | 4500 | 4500 |

| Maximum Length(mm) | 14000 | 16400 | 16400 |

| Maximum Width(mm) | 3400 | 3400 | 3400 |

| Maximum Height(mm) | 4700 | 4700 | 4700 |

| Weight(ton) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dual-axial | Dual-axial | Tri-axial |

| Crusher | ZMHC1308 | ZMHC1510 | ZMHC1512 |

| Belt Converyor under Vibrating Screen | B800×7M | B800×8M | B800×8M |

| Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS1860 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.