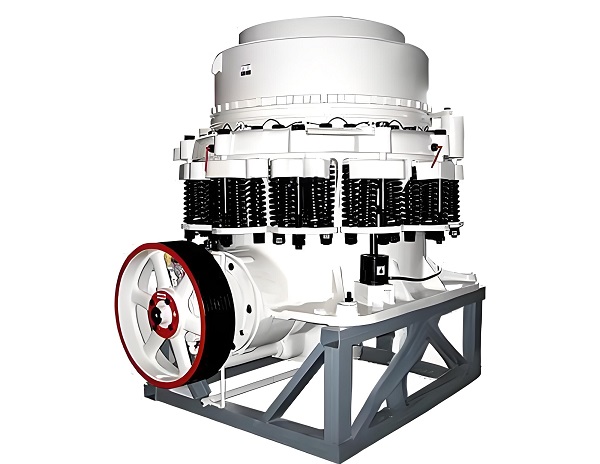

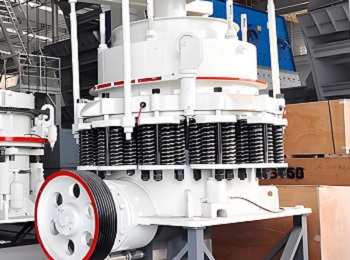

Spring cone crusher is a high-efficiency, high-power crushing equipment, widely used in environmental protection, metallurgy, construction, mining, chemical industry and other industries. Spring cone crusher has the advantages of large crushing ratio, high production efficiency and uniform product particle size. Spring cone crusher is one of the important equipment in the crushing industry.

Preface: Spring cone crusher is a high-efficiency, high-power crushing equipment, widely used in environmental protection, metallurgy, construction, mining, chemical industry and other industries.

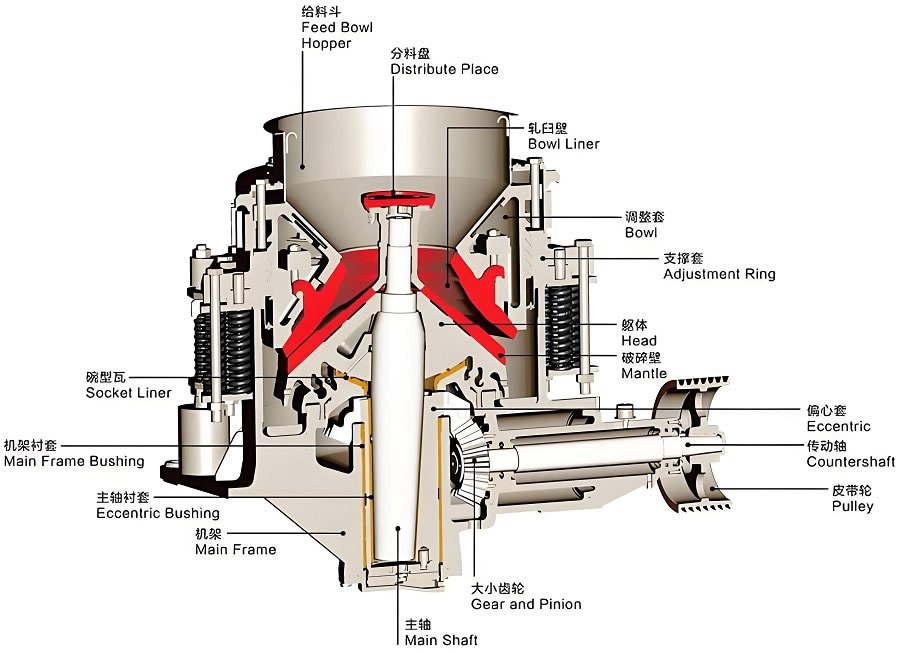

Spring cone crusher adopts advanced cone crushing principle, drives the eccentric sleeve to rotate through the motor, makes the moving cone do pendulum motion, thereby extruding, bending and shearing the material to achieve the purpose of crushing.

Spring cone crusher achieves crushing by the rotation and swing of the eccentric sleeve. When the device is working, the motor drives the eccentric sleeve through its internal elastic coupling, drive shaft and gear. When rotating, it is driven by the eccentric sleeve to produce rotation and swing. When moving, the crushing wall and the mortar wall will slowly stick together, and when rotating, it will continue to move to both sides, thereby squeezing, bending and impacting the material in the crushing chamber to achieve the goal of crushing.

1. Main features of spring cone crusher

a. Wide range of application: Spring cone crusher is suitable for crushing medium and high hardness materials, such as iron ore, copper ore, limestone, quartz, granite, basalt, diabase, etc.

b. High crushing efficiency: It has large crushing force, high production efficiency and high output.

c. Uniform product size: The crushed material has uniform particle size and is in a cubic shape, meeting diverse needs.

d. Stable operation: Compact structure, stable operation, easy maintenance and repair.

e. Overload protection: Equipped with a spring safety device, it can automatically adjust the size of the discharge port when encountering unbreakable objects to protect the equipment from damage.

2. The main structure of the spring cone crusher

The spring cone crusher is mainly composed of a frame, a transmission device, a hollow eccentric shaft, a drum bearing, a crushing cone, an adjustment device, an adjustment sleeve, a spring, and a hydraulic station for adjusting the discharge port.

3. Application field of spring cone crusher

Spring cone crusher is widely used in the fields of metallurgy, construction, road construction, chemical industry and phosphate industry. It is suitable for the third or fourth stage crushing of metal mine beneficiation plants, and is also suitable for building materials or non-metallic mines and civil engineering.

PS: The spring cone crusher has the advantages of large crushing ratio, high production efficiency and uniform product size. Spring cone crusher is an important equipment in the crushing industry.

1. The moving cone rotates continuously, and the crushing process and unloading process are carried out alternately and continuously along the working surface, with high productivity.

2. Provide spring protection device, which greatly reduces downtime.

3. Near the discharge port of CS cone crusher crushing chamber, there is a parallel belt with an equal gap between the movable cone and the fixed cone, so that the finished product is uniform in size.

4. Symons cone crusher adopts two sealing methods of dry oil or water, so that dust and impurities cannot enter the body, thus ensuring the cleanness of the lubricating oil, prolonging the service life of sliding bearings and thrust ball bearings, and making the machine run reliably.

5.Conduct market research before making a choice to understand the performance, price, user feedback, and other information of different brands and models of spring cone crushers.

6.Based on production needs and material characteristics, compare different brands and models of crushers and choose the equipment that best suits your production needs.

Cone crusher insurance system adopts spring overload protection, dry oil (or water) in the form of the seal to improve performance.

Easy maintenance, and easy to operate. Laminated crushing process makes the final material in good grain shape.

Heavy-duty design and use of high-quality components with optimized wear parts keep the operating costs down.

The internal structure has good sealing performance, reinforced ribs are installed in heavy load areas, and spring type protective devices are provided, with a long service life. Reasonable design, strong applicability, higher production capacity, and better quality.

Cone crusher is a compression type of stone crusher. The feeding rock is crushed by squeezing or compressing the feed material between a wear resistant mantle and a manganese concave or a bowl liner.

The mantle is a moving part that gyrates in an eccentric motion though an eccentrically gyrating spindle. When rock enters the top of the cone crusher, it is squeezed between the mantle and the bowl liner or concave, as the eccentric spindle rotates to cause the compression within the chamber. The material gets smaller as it moves down through the wear liner as the opening in the cavity gets tighter. Large pieces of ore are broken once, and then fall to a lower position where they are broken again. This process continues until the pieces are small enough to fall through the narrow opening at the bottom of the crusher. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Spring system plays the role of overload protection, which will enable the exotic materials or steel piece to pass through the crushing chamber without any damage to the machine.

| Model | Cone Dia. (mm) | Max. Feed Size (mm) | Adjusting Range of Output Size(mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| ZSC-600 | 600 | 65 | 12-25 | 15-25 | 30 | 2800×1300×1700 |

| ZSC-600 | 600 | 35 | 3-15 | 5-23 | 30 | 2800×1300×1700 |

| ZSC-900 | 900 | 115 | 15-50 | 50-90 | 55 | 3050×1640×2350 |

| ZSC-900 | 900 | 60 | 5-20 | 20-65 | 55 | 3050×1640×2350 |

| ZSC-900 | 900 | 40 | 3-13 | 15-50 | 55 | 3050×1640×2350 |

| ZSC-1200 | 1200 | 145 | 20-50 | 110-200 | 110 | 4152×2300×2980 |

| ZSC-1200 | 1200 | 100 | 8-25 | 50-150 | 110 | 4152×2300×2980 |

| ZSC-1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 4152×2300×2980 |

| ZSC-1750 | 1750 | 215 | 25-60 | 280-480 | 160 | 4870×3800×4192 |

| ZSC-1750 | 1750 | 185 | 10-30 | 115-320 | 160 | 4870×3800×4192 |

| ZSC-1750 | 1750 | 85 | 5-15 | 75-230 | 160 | 4870×3800×4192 |

| ZSC-2200 | 2200 | 300 | 30-60 | 590-1000 | 280 | 7705×3430×4852 |

| ZSC-2200 | 2200 | 230 | 10-30 | 200-580 | 280 | 7705×3430×4852 |

| ZSC-2200 | 2200 | 100 | 5-15 | 120-340 | 280 | 7705×3430×4852 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.