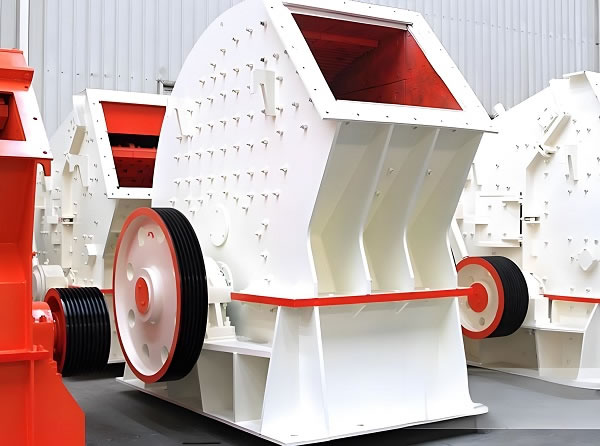

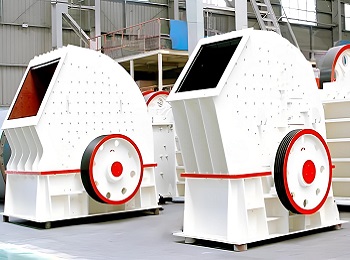

Heavy hammer crusher is the most advanced equipment in the hammer crusher series. Heavy hammer crusher is widely used in environmental protection, cement, mining, coal preparation, power generation, chemical industry and building materials industries. It has a simple structure, large crushing ratio, high production efficiency, and can adjust the output particle size according to user needs to meet different needs.

The heavy hammer crusher is an important member of the crushing equipment. With its unique performance characteristics and wide range of applications, it plays an important role in many industries such as mining, cement, coal, metallurgy, and building materials. The following is a detailed introduction to the heavy hammer crusher.

1. Definition and working principle

The heavy hammer crusher, also known as the heavy hammer crusher, is a device that uses a high-speed rotating hammer to impact, crush and grind materials. Its working principle is simple and efficient: the motor drives the rotor to rotate at high speed, and the hammer on the rotor then strikes and crushes the material entering the crushing chamber. After being impacted by the hammer, the material will be further thrown to the wall plate or impact plate of the crushing chamber, and will be impacted and crushed by the hammer again until it reaches the required particle size. Finally, the crushed material is discharged from the crushing chamber through the discharge port and enters the next processing stage or collection.

2. Performance characteristics

a. Efficient fine crushing: The heavy hammer crusher integrates stone crushing and stone shaping, with large feed particle size, small discharge particle size, and high crushing efficiency.

b. Large crushing ratio: The heavy weight of the hammer and the high rotor speed make the equipment have a large crushing ratio and output.

c. Flexible adjustment: The discharge particle size is adjustable and the adjustment range is wide. The gap between the hammer and the liner can be adjusted according to user needs to change the discharge particle size.

d. Strong adaptability: It can handle materials with high water content without blocking, and can crush a variety of medium hardness and brittle materials.

e. Wear-resistant and durable: The hammer is made of high-chromium alloy material, with high tensile strength and wear resistance, and long service life.

f. Simple structure: The equipment has a simple structure, convenient maintenance, and easy replacement of wearing parts, which reduces maintenance costs.

3. Application scope

Heavy hammer crusher is widely used in environmental protection, mining, cement, coal, metallurgy, building materials and other industries. Specifically, it can be used to crush limestone, coal, iron ore and other materials, and provide high-quality sand and gravel aggregates for infrastructure construction such as highways, railways, water conservancy, airports, etc. In addition, heavy hammer crusher can also be used to make industrial raw materials such as abrasives, refractory materials, cement, etc.

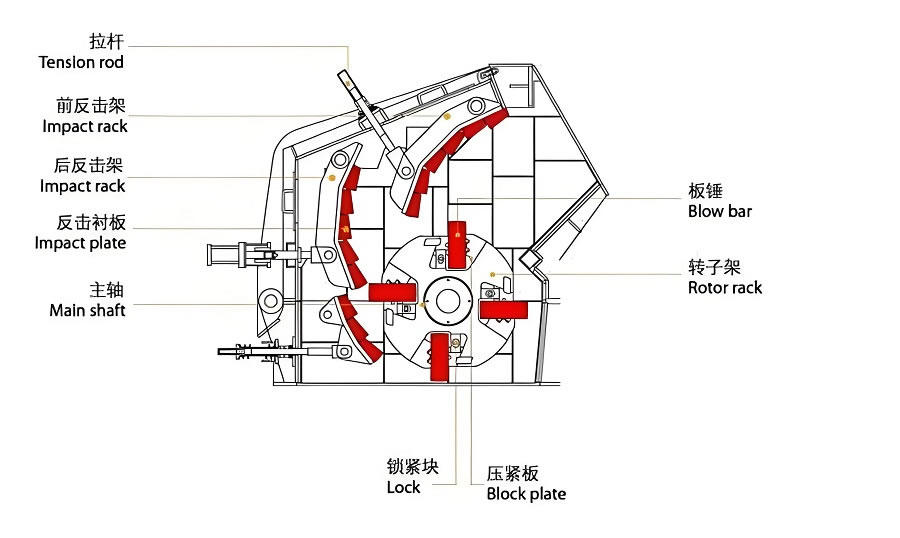

4. Equipment structure and composition

The heavy hammer crusher is mainly composed of a frame, a transmission device, a rotor, a hammer head, an impact lining plate, a screen plate, etc.

a. Frame: It is the main supporting part of the crusher, consisting of an upper body, a lower body, two side wall plates and a bearing seat.

b. Transmission device: It is mainly composed of an electric motor, an elastic coupling and a main shaft, and is used to drive the rotor to rotate at high speed.

c. Rotor: It is the main working part of the crusher, consisting of a main shaft, a hammer disc, a pin shaft and a hammer head, etc.

d. Hammer head: It is the main force for crushing materials, fixed on the hammer disc by a pin shaft, and moves with the rotation of the rotor.

e. Impact lining plate: It is used to withstand the impact and grinding of materials, and has excellent wear resistance and impact resistance.

f. Screen plate: It is used to screen the crushed materials so that the materials that meet the particle size requirements can be discharged from the crushing chamber through the screen holes.

PS: The heavy hammer crusher plays an important role in many industries with its high-efficiency fine crushing, large crushing ratio, flexible adjustment and strong adaptability. With the continuous advancement and innovation of technology, the heavy hammer crusher will further enhance its performance and application scope, providing more efficient and reliable crushing solutions for more fields.

1. With large crushing ration, heavy hammer crusher feeding granularity is large and discharge granularity is small. It could reduce the crushing stage and can save some equipment investment.

2. The heavy hammer crusher integrates coarse crushing and shaping functions when crushing stone. It does not need to go through the secondary crushing and shaping process.

3. With triple crushing force, the hammer head hits the material, the material hits the impact plate at high speed, and the stone rebounded by the impact plate hits the material hit by the hammer head. So PCZ hammer crusher can be more productive and energy-saving.

4. The heavy hammer crusher adopts a large blow bar to replace the hammer head of the original light hammer crusher. After optimized design, the kinetic energy is greater and the service life is longer.

5.The maintainability and reliability of the equipment are crucial for the stable operation of the production line. Choosing equipment that is easy to maintain and has a low failure rate can reduce downtime and maintenance costs.

In summary, when selecting a heavy-duty hammer crusher, it is necessary to comprehensively consider material characteristics, production capacity, economic benefits, environmental requirements, equipment performance, and other factors. By comprehensively evaluating these factors, the most suitable heavy-duty hammer crusher for one's production needs can be selected.

High capacity and low energy consumption.Simple structure and easy maintenance.

Lower investment and get profits quickly.Low power, low cost, and high crushing ratio.

The heavy-duty hammer crusher has the advantages of low operating cost, small supporting power, low production cost, large feeding particle size, high crushing ratio, and small product particle size

Reduce the risk of clogging and adhesion with wet and much soil raw materials using no grate design.

Motor drives the rotor quickly in the crushing cavity. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them.

Without the grate design, wet and much soil raw material will not clogged. Finally, the finished porduct through the outlet smoothly.

Under the drive of the motor, the rotor disk drives the hammer head to make high-speed circular motion. When the material enters the crushing chamber, large pieces of material are stacked on the specially designed middle support bar inside the machine. After crushing, materials with particle size larger than the required size are sent along the tangent direction of the hammer head to the impact plate for further crushing, so as to achieve coarse and medium crushing in one step. Finally, materials that meet the requirements are discharged after being uniformly leveled by the grate plate.

| Model | Feeding Size (W*L)(mm) | Rotor Size (Dia.xL)(mm) | Input Size(mm) | Power(KW) | Capacity(t/h) | Overall Dimension (mm) |

| ZHC-0808 | 800*5000 | 850*790 | ≤450 | 55-75 | 50-90 | 1760*1700*1540 |

| ZHC-1308 | 850*800 | 1310*790 | ≤600 | 55*2 | 100-160 | 2818*2100*2390 |

| ZHC-1510 | 1000*850 | 1500*950 | ≤750 | 132*2 | 160-210 | 3260*2370*2750 |

| ZHC-1512 | 1210*900 | 1500*1160 | ≤750 | 160*2 | 220-350 | 3260*2580*2750 |

| ZHC-1615 | 1500X1200 | 1650*1452 | ≤1000 | 200*2 | 350-500 | 3456*2915*3185 |

| ZHC-2015 | 1500X1400 | 2000*1500 | ≤1200 | 315*2 | 500-800 | 3880*2990*3560 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.