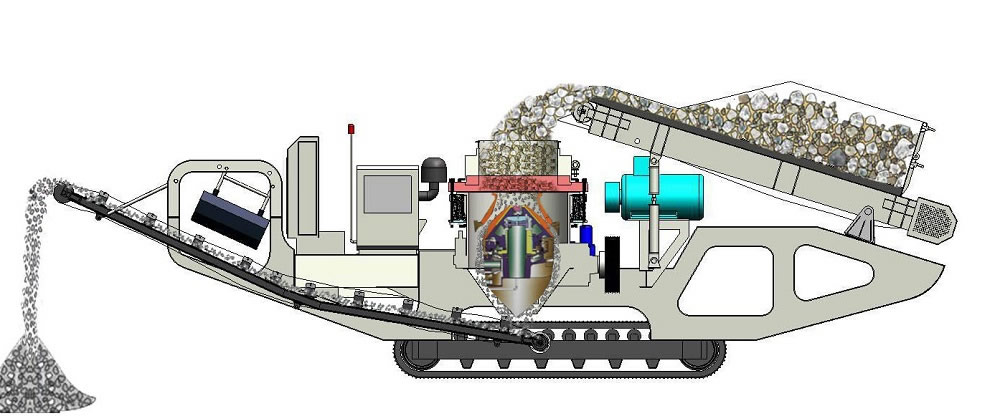

Mobile impact crushing plant is a highly efficient and flexible crushing equipment. It adopts self-driving mode. Each component is fixed on an integral frame, and tires or crawlers are attached to form a movable sand production line. It is widely used in the fields of mines, coal mines, garbage and construction waste recycling, and occupies an important position in the crushing industry.

Mobile impact crushing plant(Mobile impact crushing station) is an efficient and flexible crushing equipment. Mobile impact crushing plant adopts the impact crushing principle and crushes the material by the impact force. The crushing force acts instantaneously, so the crushing efficiency is high, the crushing ratio is large, and the energy consumption is low.

Mobile impact crushing station is widely used in many fields, including but not limited to:

1. Crushing and screening of ores such as mines and coal mines.

2. Recycling of construction waste, as well as site operations such as earthwork projects, urban infrastructure, roads or construction sites.

3. Artificial sand making of river pebbles and mountain stones (such as limestone, granite, basalt, etc.).

Performance characteristics of mobile impact crushing plant:

1. Integrated design: crusher, vibrating screen, belt conveyor and other equipment are installed in an integrated manner, with a compact structure and space saving.

2. High mobility: the equipment adopts a vehicle-mounted chassis, tire or crawler drive, with a small turning radius, which is convenient for driving and stationing in complex environments.

3. Efficient crushing: equipped with a high-performance impact crusher, high crushing efficiency and large crushing ratio.

4. Flexible combination: It can be customized according to customer needs to meet different crushing and screening needs.

Mobile impact crushing plant have been widely used in many fields due to their high efficiency, flexibility, and convenient combination.

Choosing the appropriate mobile cone crusher requires consideration of multiple factors to ensure that the selected equipment can meet your production needs and budget. Here are some key selection guidelines:

1.Clarify your crushing production requirements. Different specifications of mobile cone crushers have different production capacities, and the larger the specification, the higher the corresponding production capacity. Generally speaking, the output range of mobile stone crusher equipment is between 100-650 tons/hour.

2.Determine the most suitable type of crusher based on the characteristics of the material you want to handle, such as hardness, brittleness, moisture content, etc.

3.Different types of mobile cone crushers have different specifications and costs, so it is necessary to make a choice based on one's own investment budget.

4.Choosing a highly automated cone crusher can help reduce failure rates and improve production efficiency.

5.If conditions permit, you can visit the equipment manufacturer's factory or actual usage site to gain a more intuitive experience.

Sealing devices, dust removal devices, noise reduction devices, etc. ensure green production and strong energy-saving and environmental protection performance.

The integrated installation and coordinated operation of the entire unit fully demonstrates its advantages of convenience and flexibility.

The hydraulic system can control the feeding and unloading of equipment, folding of conveyor belts, and other actions. The PLC intelligent operating system is safe, reliable, and easy to operate.

Cone tire mobile station is the main crusher for aggregate production and concrete and asphalt recycling applications, with flexible and adaptable configuration

A mobile cone crusher is a device used for crushing hard materials such as building concrete, rocks, and ores. It combines the crushing capacity of a cone crusher with the flexibility of a mobile platform. This type of crusher is commonly used in fields such as garbage screening, quarrying, mining, and construction waste recycling.

The working principle of the mobile cone crusher mainly includes the following aspects:

1. Feeding system: The mobile cone crusher feeds the material to be crushed into the crushing chamber through a feeding belt or vibrating feeder.

2. Crushing process: Fixed cone (shell) and movable cone: Inside the crushing chamber, there is a fixed shell (i.e. fixed cone) with a rotatable conical crushing head (i.e. movable cone) inside. The movable cone is driven by an eccentric shaft to perform pendulum motion. Squeezing and crushing: When the movable cone approaches the fixed cone, the gap between the two decreases, and the material is crushed by compression. Discharge process: As the movable cone moves away from the fixed cone, the crushed material will be discharged from the bottom of the crushing chamber.

3. Discharge adjustment: In order to adapt to different particle size requirements, the size of the crushing chamber can be changed by adjusting the position of the movable cone, thereby controlling the particle size distribution of the final product.

4. Mobility: The mobile cone crusher is equipped with a trailer chassis or a self-propelled mechanism, which can flexibly move between work sites, reducing transportation costs and installation time.

5. Auxiliary system: In addition to the main crushing components, the mobile cone crusher may also be equipped with screening systems, conveyor belts, and other auxiliary facilities to form a complete crushing production line.

6. Control system: Advanced electronic control systems are usually used to monitor and adjust various parameters during the crushing process, ensuring crushing efficiency and product quality.

In summary, the mobile cone crusher is an efficient, flexible, and easy to operate crushing equipment that plays an important role in garbage screening and various industrial applications.

| Model | ZCMC120SMHS | ZCMC180SMHS | ZCMC180SMH | ZCMC250SMHS | ZCMC250SMH | |

| Transport size | ||||||

| Length(mm) | 11200 | 11800 | 10000 | 12300 | 10816 | |

| Width(mm) | 2743 | 2743 | 2480 | 2900 | 2743 | |

| Height(mm) | 4200 | 4200 | 4160 | 4200 | 4160 | |

| Alex weight(kg) | 15500 | 16300 | 14300 | 31100 | 22900 | |

| King pin weight(kg) | 12900 | 14200 | 8100 | 17600 | 12800 | |

| Cone crusher | ||||||

| Model | ZCMH120 | ZCMC180 | ZCMC180 | ZCMC250 | ZCMC250 | |

| Max Feed opening(mm) | 160 | 180 | 180 | 240 | 240 | |

| setting range(mm) | 22-32 | 22-32 | 22-32 | 26-51 | 26-51 | |

| Vibrating screen | ||||||

| Model | 3YK1545 | 4YK1548 | ||||

| Belt conveyor | ||||||

| Model | B800X8 | B1000X8 | B1000X8 | |||

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.