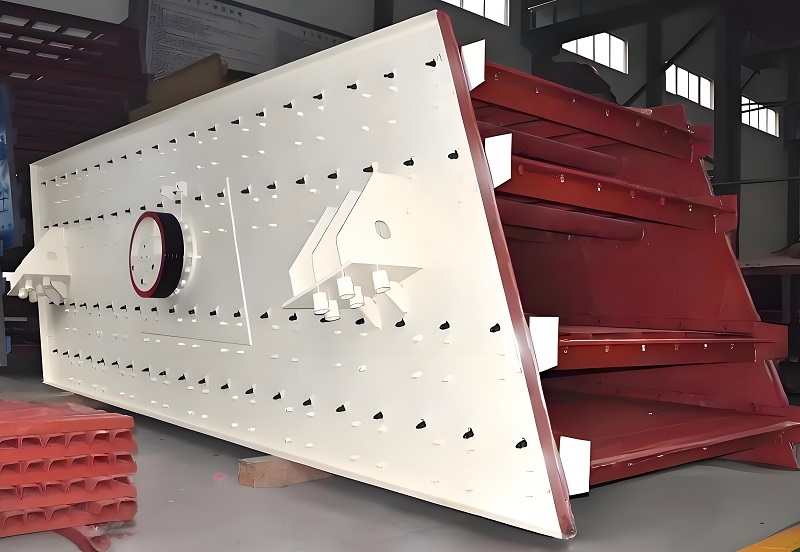

A circular vibrating screen is a high-efficiency device that uses the centrifugal force generated by a vibrator to drive the screen body in circular vibration, achieving material classification and screening. It is widely used in industries such as mining, metallurgy, coal, and building materials. Its operational stability and screening efficiency directly depend on the standardization of installation and commissioning. Scientific and reasonable installation and commissioning can fully utilize the equipment's performance, extend its service life, reduce the failure rate, and ensure production safety. This article, based on the structural characteristics of circular vibrating screens and field application experience, details its installation preparation, installation steps, commissioning procedures, and precautions, providing professional and practical guidance for on-site operation and helping enterprises achieve efficient and safe production.

1. Pre-Installation Preparation

Comprehensive pre-installation preparation is crucial to ensuring the orderly progress of installation work and avoiding subsequent rework. It mainly covers three core aspects: site preparation, equipment inspection, and tool and auxiliary material preparation. Site selection must meet the needs of equipment operation and subsequent maintenance. Priority should be given to flat, firm, dry, and well-ventilated areas. The equipment foundation must be constructed of high-strength concrete, with a strength reaching at least 85% of the design standard, capable of withstanding the dynamic loads during equipment operation. The surface flatness error of the foundation should not exceed 0.5mm/m. A maintenance passage of at least 1.2m should be reserved, avoiding the accumulation of debris and obstacles around the foundation to prevent collisions during operation.

Equipment inspection requires verifying the integrity and condition of each component, with a focus on core components such as the screen box, vibrator, motor, springs, screen mesh, and bearings. Confirm that the model and specifications match the design requirements, and that there are no issues such as deformation, damage, or corrosion. Check that the vibrator has sufficient internal lubricating oil and that the oil quality is up to standard; that the motor terminals are intact; that the screen mesh is undamaged or loose; that the springs are not aged or deformed; and that bolts and other fasteners are complete. Tools and auxiliary materials must be prepared in advance, including lifting equipment, a level, torque wrench, screwdrivers, wrenches, sealant, lubricating oil, and gaskets, to ensure a smooth installation process.

2. Standard Installation Procedures

The installation of a circular vibrating screen must follow the sequence of "foundation leveling—base installation—vibrator and motor installation—screen body assembly—component fixing—electrical connection." Step-by-step operation and precise control are crucial to ensure that all components are securely connected and accurately positioned, avoiding equipment malfunctions caused by installation deviations.

First, level the foundation and install the base. Place the base stably on the pre-set concrete foundation. Use a level to check the base's levelness, adjusting shims to ensure that the horizontal error in all directions does not exceed 0.3mm/m, ensuring even force distribution at the four corners of the base. If there are gaps between the base and the foundation, fill them tightly with steel plates; do not use any debris as a base. Anchor bolts are fixed using secondary grouting. After grouting, allow at least 72 hours for curing. After the concrete has solidified, tighten the bolts using a torque wrench according to standards. For M16 bolts, control the tightening force to 35-40 N·m. After tightening, install lock nuts to prevent loosening during operation.

Next, assemble the vibrator, motor, and screen body. Install the vibrator smoothly onto the mounting base at the bottom of the screen body, ensuring a tight connection between the vibrator and the screen body, with bolts tightened securely. The vibrator axis should be aligned with the center line of the screen body, with a deviation not exceeding 0.2mm. Install the motor in the preset position on the base, ensuring the motor axis is parallel to the vibrator axis, with a center distance error not exceeding 0.5mm. Connect via a coupling, with the coupling clearance controlled at 2-3mm to avoid interference during operation. Select the appropriate mesh size for the screen according to the material grading requirements. During installation, tension the screen evenly and secure it firmly with pressure strips, ensuring no looseness or wrinkles. For multi-layer screens, install them layer by layer according to the screen aperture size, from coarse to fine, with a layer spacing of not less than 120mm. Ensure good sealing between layers to prevent material mixing.

Finally, perform electrical system connections and component inspection. Strictly follow the electrical schematic diagram for wiring, ensuring the power supply voltage matches the equipment's rated voltage. Use flame-retardant cables that meet specifications, ensure secure and reliable wiring terminals, and implement proper grounding, overload, and leakage protection devices to prevent electrical faults from causing safety accidents. After wiring is complete, check the connections of all components to ensure there is no looseness or interference, that the springs are accurately positioned and evenly stressed, and that the screen body is free from jamming.

3. Scientific Commissioning Process

After installation, parameters should be gradually optimized through two stages: no-load commissioning and load commissioning. Potential faults should be identified and the equipment ensured to reach its optimal operating state. During commissioning, dedicated personnel must monitor the process throughout and address any abnormalities promptly.

No-load commissioning should last at least 2 hours. After starting the equipment, observe whether the screen body vibration is stable and uniform, and whether there is any abnormal noise, violent vibration, or loose components. Pay special attention to monitoring the operating temperature of the motor and vibrator, recording it every 30 minutes to ensure the temperature does not exceed 75℃ and the bearing temperature does not exceed 80℃. Simultaneously check the screen tension and spring deformation, confirming that the screen cleaning assembly operates flexibly without jamming or abnormal noise. If uneven vibration occurs, check whether the vibrator eccentric block angle is consistent and whether the bolts are loose. If abnormal noise occurs, check the bearing lubrication or component interference; resolve the fault before continuing commissioning.

After successful no-load commissioning, proceed to load commissioning. Feed materials in small batches evenly, adjusting core operating parameters according to material characteristics (particle size, moisture content, hardness). Amplitude is generally controlled at 4-8mm, frequency at 1400-1800 r/min, and screen angle at 15°-20°. Increase the angle and amplitude appropriately for coarse particles and decrease them appropriately for fine powders and wet, sticky materials to balance screening efficiency and accuracy. Observe the material trajectory, discharge, and screening effect. If material accumulation or deviation occurs, adjust the feed speed or distributor position. If screening accuracy is insufficient, optimize amplitude, frequency, or screen mesh size. If output does not meet standards, check for screen blockage and sufficient vibration force, and promptly clean residual material from the screen surface. After stable load commissioning, run continuously for 6-8 hours, then conduct a comprehensive check of all components. Only after confirming no abnormalities can normal production commence.

4. Installation and Commissioning Precautions

During installation and commissioning, safety regulations and operating standards must be strictly followed, with particular attention to the following:

First, forcibly assembling components during installation is strictly prohibited to avoid damaging the equipment structure, bearings, or screen. Bolts must be tightened evenly, and critical parts must be repeatedly checked to ensure no loosening.

Second, before commissioning, all lubrication points must be checked, and qualified lubricating oil or grease must be added. Regular replenishment is necessary to reduce component wear.

Third, during equipment operation, operators must stay away from the screen body, vibrator, and other moving parts. Disassembling components, adjusting parameters, or cleaning materials during operation is strictly prohibited to avoid accidents.

Fourth, if a malfunction occurs during commissioning, the machine must be stopped immediately and the power disconnected. The fault must be identified and properly resolved before restarting; operation with a malfunction is strictly prohibited.

Fifth, after installation and commissioning, relevant records must be compiled, including installation parameters, commissioning data, and fault handling details, to provide a basis for subsequent maintenance.

Sixth, daily use must follow the principle of "start the machine first, then feed materials; stop the material first, then stop the machine." The integrity of the screen and the tightness of fasteners must be checked regularly.

The installation and commissioning of a circular vibrating screen are crucial for ensuring the efficient and safe operation of the equipment. Strict adherence to standardized procedures and meticulous attention to every detail are essential. From comprehensive pre-installation preparation to precise operation during installation, and then to parameter optimization and troubleshooting during the commissioning phase, each step directly impacts the equipment's performance and lifespan. Only through standardized installation and scientific commissioning can the equipment's screening efficiency be fully realized, failure rates reduced, production efficiency and product quality improved, and the equipment's lifespan extended. This provides a reliable guarantee for large-scale production, helping enterprises achieve their energy-saving, efficient, and safe production goals.

Save Time! Get A Detailed Quotation Quickly.