The resource recovery and harmless treatment of municipal solid waste is a core direction of global environmental development. As the core hub of waste treatment, the screening production line undertakes the crucial mission of waste grading, impurity separation, and resource recovery. A complete municipal solid waste screening production line is not a collection of individual pieces of equipment, but rather a collaborative system comprised of four major components: pretreatment, core screening, auxiliary sorting, and conveying and storage. Each component has a clear division of labor and works in close coordination to achieve refined sorting and resource recovery of mixed municipal solid waste. The following section breaks down the complete components of the production line in detail, explaining the core functions of each part to help you fully understand the operational logic of the entire municipal solid waste screening process.

The core objective of a municipal solid waste screening production line is to transform mixed waste of diverse composition and form into recyclable and harmlessly disposable classified materials. Its composition must be adapted to the characteristics of municipal solid waste—high moisture content, strong viscosity, and disordered composition—while balancing sorting efficiency and classification accuracy. The entire production line follows a process of "pre-treatment and impurity removal—core grading—precision sorting—conveyance and storage." Each system works in concert and is indispensable. This not only solves the pain points of incomplete sorting and low efficiency of individual equipment but also achieves large-scale, standardized operation of waste treatment. It is widely used in municipal solid waste treatment plants, waste transfer stations, and resource recycling centers.

The pre-treatment system is the front-end guarantee of the municipal solid waste screening production line. Its core function is to remove large debris, sharp objects, and obvious impurities from the mixed waste, preventing them from damaging subsequent equipment and clogging the screening channels. It also reduces the stickiness of the waste and optimizes sorting conditions, laying the foundation for the subsequent core screening stage. The pre-treatment system mainly consists of three core parts: a feeding device, a manual sorting platform, and crushing equipment. These parts work together to achieve initial purification of the waste.

The feeding device, as the "entry point" of the production line, mainly includes equipment such as a feeding hopper and conveyor. Its core function is to evenly and stably transport the collected mixed municipal solid waste to the subsequent processing stages, avoiding equipment congestion due to excessively rapid feeding or reduced production efficiency due to excessively slow feeding. The feed hopper temporarily stores waste, buffering the feeding pressure, and is equipped with a grid device to initially intercept large pieces of waste. The conveyor is responsible for smoothly transporting the waste, and its angle and length can be flexibly adjusted according to the production line layout to ensure a smooth feeding process and reduce manual handling costs.

The manual sorting platform is a key component of the pre-processing system, typically located above the conveyor. Its core function is to manually screen out debris unsuitable for mechanical sorting, especially sharp, flammable, explosive, and large, difficult-to-crush items, such as discarded furniture, glass shards, metal objects, and large plastic items. Manual sorting compensates for the limitations of mechanical sorting, preventing sharp objects from scratching equipment screens and conveyor belts, preventing safety hazards caused by flammable and explosive materials, and allowing for the initial recovery of high-value recyclables, improving resource recovery efficiency and ensuring the safe and stable operation of subsequent equipment.

The crushing equipment is mainly used to process large or lumpy waste that remains after pre-processing. Its core function is to crush it to a suitable particle size for subsequent grading by the core screening equipment. Large items in municipal solid waste (such as discarded appliance casings, large pieces of plastic, and clumped kitchen waste) cannot directly enter the screening equipment. Through the squeezing and impact of the crushing equipment, these items are broken into fine particles. This improves screening efficiency, fully exposes recyclable components in the waste for subsequent precise sorting, and reduces waste volume, lowering subsequent disposal costs.

The core screening system is the "core hub" of the entire production line and a key link in achieving waste grading. Its core function is to grade the pre-treated waste according to particle size and material characteristics, separating materials of different specifications to provide a foundation for subsequent precise sorting and resource utilization. The core equipment of the core screening system consists of various screening machines. Depending on the characteristics of municipal solid waste, mainstream configurations include trommel screens and vibrating screens. Some large-scale production lines also incorporate bouncing screens. These various machines work together to achieve fine grading.

The trommel screen is the main equipment in the core screening system, suitable for municipal solid waste with high moisture content and high viscosity. Its core function is to achieve coarse and medium grading of the waste. Its main body is an inclined rotating drum with screens of different aperture sizes inside. After the waste enters the drum, as it rotates, fine particles (such as kitchen waste and fine dust) fall through the screens, while coarse particles (such as inert waste and large pieces of recyclables) are discharged from the end of the drum. Simultaneously, scrapers on the inner wall of the drum clean sticky materials, preventing screen clogging and ensuring stable screening efficiency.

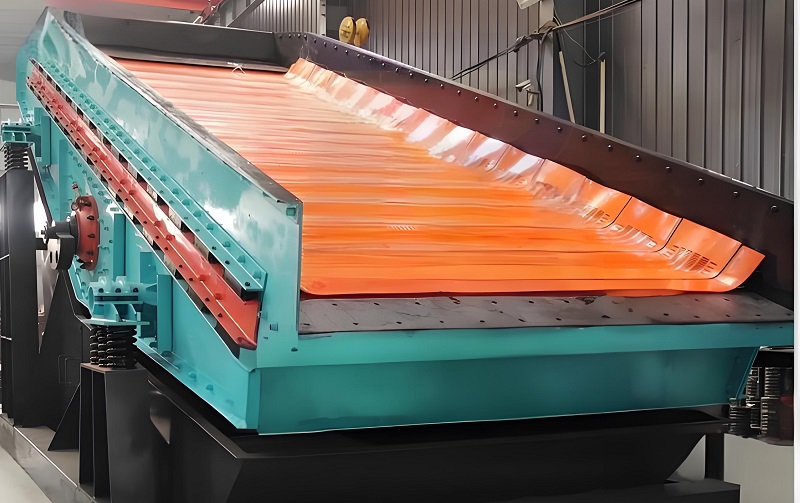

Vibrating screeners are usually used in conjunction with trommel screeners. Their core function is to achieve fine classification of waste, especially suitable for separating fine-particle materials. Utilizing the vibration generated by a vibrating motor, the waste reciprocates on the screens. Depending on the screen aperture size, fine materials can be further separated into different sizes, such as separating kitchen waste from small recyclables (such as small plastics and paper scraps), improving classification accuracy. It can also screen out fine-particle materials that meet recycling standards, providing a guarantee for subsequent resource utilization.

The auxiliary sorting system is a crucial step in achieving precise waste sorting and enhancing resource recycling value. Its core function, building upon the core screening and grading process, is to separate various recyclable materials from hazardous impurities based on their density, magnetism, and material properties, thus achieving resource recovery and harmless waste treatment. The auxiliary sorting system mainly consists of air separation equipment, magnetic separation equipment, and a manual fine sorting platform. Some high-end production lines also incorporate intelligent sorting equipment to further improve sorting accuracy and efficiency.

Air separation equipment, based on aerodynamic principles, is designed to separate lightweight and heavy materials from waste. For example, it separates lightweight recyclable materials such as plastic film, paper scraps, and wood chips from heavy materials such as bricks, metals, and kitchen waste. Lightweight materials can be collected for recycling, while heavy materials proceed to subsequent processing stages. This improves the recovery rate of recyclables and reduces the impurity content in heavy materials, optimizing subsequent treatment outcomes. The core function of magnetic separators is to separate metallic materials from waste, such as nails, wires, and scrap metal parts. Strong magnetic fields attract these materials, enabling metal recovery while preventing them from entering subsequent equipment and causing wear or malfunctions.

The conveying and storage system is the "logistics support" for the entire production line. Its core function is to smoothly transport materials processed at each stage to designated locations, while also temporarily storing various sorted materials to ensure continuous operation and seamless connection between processing stages. The conveying system mainly consists of belt conveyors and screw conveyors, which can be flexibly configured according to material characteristics and production line layout to facilitate material transport between different stages and equipment, preventing material accumulation. The storage system mainly consists of various storage bins to store sorted recyclables, kitchen waste, and inert waste, facilitating subsequent transfer, disposal, or resource utilization. It also buffers production pressure, ensuring continuous and stable operation of the production line.

A complete municipal solid waste screening production line, through the coordinated operation of four major systems—pretreatment, core screening, auxiliary sorting, and conveying and storage—achieves the transformation of mixed municipal solid waste "from chaotic to orderly" and "from waste to recycling." With clearly defined functions and close collaboration among its components, the system ensures both efficiency and precision in waste treatment while maximizing resource recovery. It reduces the environmental pressure from landfill and incineration, making it a core piece of equipment for promoting the harmless, reduced, and resource-oriented development of municipal solid waste. As technology advances, the municipal solid waste screening production line is upgrading towards intelligence, efficiency, and environmental friendliness, further optimizing system configurations, enhancing processing capacity and resource recovery value, and providing strong support for global environmental protection.

Save Time! Get A Detailed Quotation Quickly.