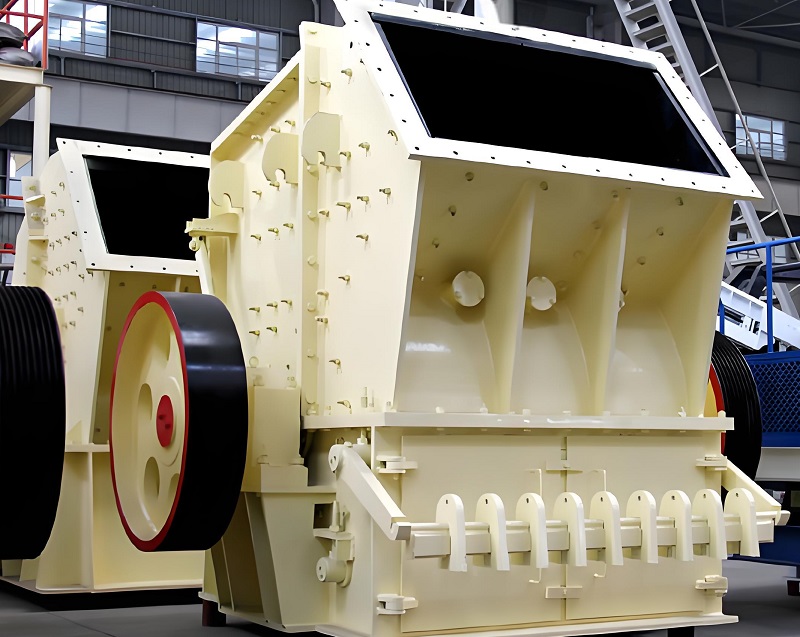

As the core crushing equipment in industries such as mining, building materials, and infrastructure, the operational efficiency of hammer crushers directly affects production capacity and overall costs. Currently, some enterprises have insufficient equipment processing capacity, high energy consumption, and frequent malfunctions due to improper selection, non-standard operation, and lagging maintenance. With the upgrading of industrial production's demand for high efficiency and low carbon, improving the efficiency of hammer crushers has become an urgent need in the industry. This article provides a systematic solution from four core dimensions: selection and adaptation, operation optimization, maintenance, and structural transformation, combined with specific working conditions and practical data, to help enterprises break through efficiency bottlenecks, achieve cost reduction, efficiency improvement, and stable production.

A. Scientific selection and adaptation to working conditions: the fundamental prerequisite for efficiency improvement

The efficiency of a hammer crusher is directly related to the matching degree of material characteristics and equipment models, and precise selection is the primary step in improving efficiency.

1. Material pretreatment and feature adaptation

The humidity, hardness, and particle size of raw materials are key factors affecting crushing efficiency. For viscous materials with a moisture content exceeding 15% (such as wet coal and sludge), it is necessary to reduce the moisture content in advance through a dryer to avoid material adhesion and blockage in the crushing chamber, resulting in a decrease of more than 30% in processing capacity; For high hardness materials such as granite and basalt with a Mohs hardness of 7 or above, heavy-duty hammer crushers (such as the PCZ series) should be selected. The hammer shaft is forged with high-strength alloy steel, and the hammer head is made of high chromium alloy or hard alloy material. The wear resistance is 2-3 times higher than that of ordinary high manganese steel hammer heads, which can avoid efficiency degradation caused by rapid wear of the hammer head. At the same time, the particle size of the raw material should match the size of the feeding port, and the feeding particle size should not exceed 80% of the rated feeding port of the equipment. Overly large materials are prone to getting stuck in the feeding port and require additional manual processing, which affects the efficiency of continuous operation.

2. Equipment models accurately match production capacity requirements

Select equipment with appropriate processing capacity based on production scale, avoiding "big horses pulling small cars" or "small horses pulling big cars". For example, small quarries (with a daily processing capacity of less than 500 tons) can use PC-800 × 600 hammer crushers with a motor power of 37 kW and a processing capacity of 10-30 t/h; Large mines or infrastructure projects (with a daily processing capacity of over 2000 tons) should use the PCZ-1615 heavy-duty hammer crusher, with a motor power of 250 kW and a processing capacity of 150-300 t/h. Its dual rotor design can achieve secondary crushing, with a crushing ratio of 10-15, reducing the pressure in the subsequent screening process. In addition, according to the requirements of the discharge particle size, the corresponding cavity type is selected. The standard cavity is suitable for medium crushing, and the short head cavity is suitable for fine crushing, to avoid over crushing or particle size non-compliance caused by improper cavity type.

B. Standardized operation and parameter optimization: real-time improvement of operational efficiency

The correct operation method and reasonable parameter settings can significantly improve crushing efficiency without increasing equipment investment.

1. Uniform feeding and stable load control

Using a quantitative feeder (such as a belt scale) to achieve uniform feeding and avoid the intermittent feeding caused by manual feeding. When the feed rate exceeds the processing capacity of the equipment, material accumulates in the crushing chamber, causing a sudden increase in motor load and easily leading to overload shutdown; Insufficient feed quantity leads to equipment idling, energy waste, and low efficiency. In an ideal state, the equipment load should be maintained at 75% -90% of the rated power. By adjusting the feeding speed, the material in the crushing chamber can be in a "full without blockage" state, which can improve processing efficiency by 15-20%. At the same time, avoid mixing with unbreakable objects such as iron blocks and steel bars. Such foreign objects can cause damage to the hammer head, lining plate, and even burn out the motor. It is necessary to install a iron remover at the feed inlet to remove impurities in advance.

2. Dynamic adjustment of core parameters

Reasonably adjust the rotor speed and discharge port size: The rotor speed directly affects the impact kinetic energy of the hammer head. The higher the speed, the higher the crushing efficiency, but the energy consumption also increases accordingly. It needs to be adjusted according to the material hardness balance. The general speed range is 800-1200r/min. When dealing with high hardness materials, the speed can be appropriately increased; The size of the discharge port is adjusted according to the requirements of the discharge particle size. If it is too small, it will increase the difficulty of crushing and reduce the processing capacity. If it is too large, it will require secondary processing by screening equipment. Generally, the size of the discharge port should be 5-10mm larger than the target discharge particle size, taking into account both efficiency and particle size qualification rate. In addition, regularly check the tightness of the belt transmission device. Belt slippage can cause speed loss, and the tensioning device needs to be adjusted in a timely manner to ensure power transmission efficiency.

C. Refined maintenance and upkeep: extend lifespan and ensure stable efficiency

The wear and tear of vulnerable parts and equipment failure of hammer crushers are the main reasons for the decrease in efficiency. Fine maintenance can effectively reduce downtime and maintain efficient operation of the equipment.

1. Regular inspection and replacement of vulnerable parts

Hammer heads, lining plates, and sieve plates are core vulnerable parts that require a regular inspection system. When the wear of the hammer head exceeds 30% of its original size, it should be flipped over or replaced in a timely manner to avoid a decrease in crushing efficiency due to insufficient impact force; The lining plate is fixed with bolts, which will increase the gap between the crushing chambers after wear. It needs to be adjusted or replaced regularly to ensure the stability of the crushing chamber volume; When the aperture of the sieve plate is blocked by more than 20%, it needs to be cleaned with a high-pressure water gun or steel brush to avoid affecting the discharge speed. Taking the PC-1000 × 800 crusher as an example, under normal working conditions, the service life of the high manganese steel hammer head is about 800 hours, and the high chromium alloy hammer head is about 1500 hours. Regularly replacing vulnerable parts can keep the equipment operating rate above 90%.

2. Maintenance of lubrication and cooling system

Bearings are critical components for equipment operation and require regular lubrication (lithium based grease is recommended). The amount of oil added should be 1/3-1/2 of the bearing chamber volume. The oil level should be checked every 200 hours of operation, and the lubricating oil should be replaced every 1000 hours to avoid bearing stagnation caused by lack of oil and heating. At the same time, ensure that the cooling system is working properly. When the ambient temperature exceeds 35 ℃, start the cooling water circulation and control the bearing temperature not to exceed 75 ℃ to prevent bearing damage caused by high temperature. In addition, regularly clean the dust inside the equipment, check the operating status of supporting equipment such as motors and reducers, and promptly deal with abnormal situations such as abnormal noise and vibration.

D. Structural upgrading and technological transformation: long-term improvement of efficiency ceiling

Through targeted structural optimization and technological transformation, the efficiency of hammer crushers can be fundamentally improved, making them suitable for upgrading old equipment or high demand production scenarios.

1. Core component upgrade

Replace traditional cast hammerheads with forged composite hammerheads, which adopt a composite structure of "high chromium alloy working layer+high manganese steel matrix", ensuring wear resistance and good toughness. The service life is increased by more than twice, and the crushing efficiency is increased by 10-15%; Install impact plates or lining plates in the crushing chamber to optimize the material movement trajectory, so that the material forms a multiple crushing process of "impact impact grinding" in the chamber, reducing the phenomenon of over crushing and improving the yield of finished products; For equipment used to handle viscous materials, ceramic wear-resistant coatings can be sprayed on the surface of the sieve plate or polyurethane screens can be installed to reduce the probability of material adhesion and shorten the cleaning time for blockages.

2. Intelligent and automated transformation

Install an intelligent monitoring system to collect real-time parameters such as motor current, bearing temperature, and rotor speed through sensors, achieve fault warning and remote diagnosis, reduce manual inspection costs, and avoid equipment downtime caused by equipment failures in advance; Adopting variable frequency speed regulation technology, the rotor speed is automatically adjusted according to the characteristics of the material and the amount of feed, maintaining stable efficiency while reducing energy consumption during fluctuations in processing capacity; For large-scale production lines, the hammer crusher is linked and controlled with equipment such as feeders, screening machines, and conveyors to achieve automated continuous operation, reduce manual intervention, and improve overall production efficiency.

3. Process optimization

The combination process of "multi-stage crushing+graded screening" is adopted, and the hammer crusher is used in conjunction with the jaw crusher and cone crusher. The coarse crushing is completed by the jaw crusher, and the hammer crusher is responsible for the medium and fine crushing, avoiding single equipment bearing heavy loads; Install a vibrating screen at the discharge port of the crusher to timely separate qualified particle size materials, avoid repeated crushing of qualified materials, reduce energy consumption, and improve overall processing efficiency. For example, a certain coal mine has optimized the process by changing the original single hammer crushing to a process of "jaw crusher+hammer crusher+vibrating screen", increasing the processing capacity from 80t/h to 120t/h and reducing unit energy consumption by 25%.

To improve the efficiency of hammer crushers, a full process optimization system of "selection operation maintenance modification" needs to be established. Scientific adaptation of material characteristics and equipment models is the foundation, standardized operation and dynamic parameter adjustment can quickly improve efficiency, refined maintenance can ensure stable efficiency, and structural upgrading and process optimization can broaden long-term improvement space. Through the collaborative efforts of the four major paths, the pain points of equipment such as insufficient output, high energy consumption, and short lifespan can be effectively solved, significantly improving processing capacity and operational stability. These solutions balance practicality and economy, and are suitable for production scenarios of different scales and working conditions, providing strong support for enterprises to reduce operating costs and enhance market competitiveness.

Save Time! Get A Detailed Quotation Quickly.