With the accelerating pace of urbanization, the amount of construction waste generated from urban renewal, old city renovation, and infrastructure construction is increasing year by year. According to statistics, my country's annual production of construction waste has exceeded 3 billion tons. If construction waste is directly landfilled, it will not only occupy a large amount of land resources but also contaminate soil and groundwater due to the leaching of harmful components, threatening ecological environment safety. As a core equipment for the resource utilization of construction waste, the impact crusher, with its advantages of high crushing ratio, uniform product particle size, and strong adaptability, can efficiently crush construction waste such as concrete blocks, bricks, and discarded road materials into recycled aggregates, achieving resource recycling. This article will detail the specific mechanisms and practical points of impact crushers in crushing construction waste from the aspects of working principle, core structure, crushing process, key influencing factors, and optimization strategies, providing technical reference for the resource utilization of construction waste.

The core principle of impact crushers in crushing construction waste is "impact crushing + repeated impact grinding." A high-speed rotating rotor drives the hammer plates to generate a strong impact on the material, while the secondary impact between the material and the impact plate, and between the materials themselves, further crushes the material. Unlike traditional compression crushers, the impact crusher relies on kinetic energy to complete the crushing process. Its working process can be divided into three core stages: First, initial impact crushing: the motor drives the rotor to rotate at high speed, and the hammer plates on the rotor gain considerable kinetic energy. When construction waste (such as concrete blocks and bricks) enters the crushing chamber, the hammer plates impact the material at high speed, causing the material to instantly gain huge kinetic energy and be thrown towards the impact plate above the crushing chamber; secondly, secondary impact crushing: after the material collides violently with the impact plate, its kinetic energy decays and it rebounds. During this process, the rebounded material collides with the new material entering the crushing chamber, forming "self-impact between materials," further refining the particle size; finally, grinding and shaping: the material, after multiple impacts and collisions, is ground in the gap between the grate bars at the bottom of the crushing chamber and the hammer plates and impact plates, finally forming recycled aggregates that meet the required particle size. Unqualified coarse materials are returned to the crushing chamber through the grate bar gaps for re-crushing until the specified particle size is reached. This multi-stage crushing mode of "impact-rebound-self-impact-grinding" not only achieves a large crushing ratio (generally 10-40), but also results in more regular particle shapes of the crushed material, meeting the requirements for recycled aggregates.

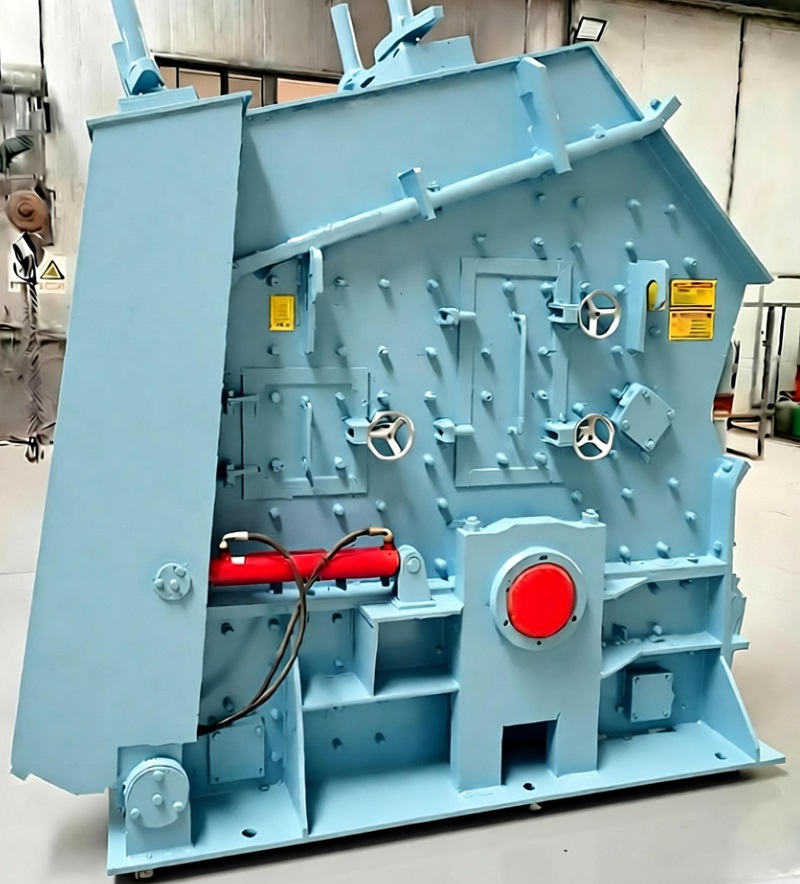

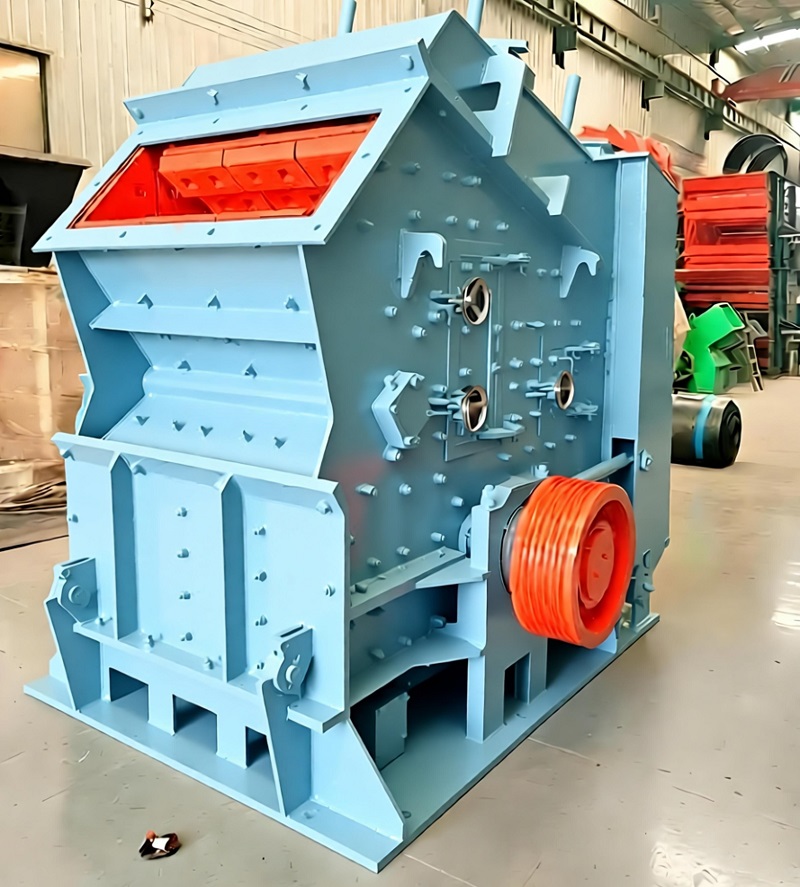

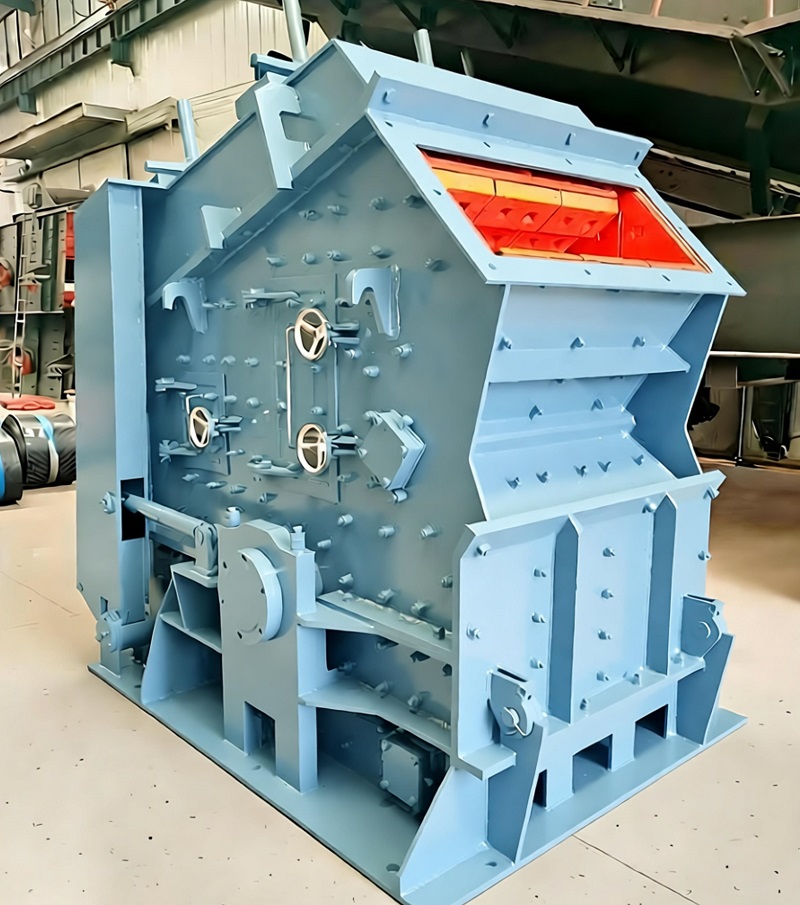

The core structural design of the impact crusher is fundamental to ensuring crushing efficiency and product quality. It mainly consists of a rotor, impact plates, counter-attack plates, crushing chamber, grate bars, driving device, and frame. The rotor is the core moving part of the equipment, composed of a main shaft, hub, and spokes. Its rotational speed directly determines the impact kinetic energy of the impact plates. The typical speed range is 500-1500 r/min, which needs to be adjusted according to the hardness of the construction waste and crushing requirements. The impact plates are key components that directly act on the material. They are made of high-strength wear-resistant materials (such as high-manganese steel, high-chromium cast iron) and fixed to the rotor with bolts. Their shape and installation angle require optimized design to ensure the impact effect on the material and their own service life. When the impact plates are worn to a certain extent, they can be quickly replaced to ensure continuous operation of the equipment. The counter-attack plates are installed above and on both sides of the crushing chamber, forming a certain crushing gap with the rotor. The gap size can be flexibly adjusted through an adjustment device, thereby controlling the particle size of the crushed product. The surface of the counter-attack plates usually uses wear-resistant liners to reduce impact wear. The grate bars are installed at the bottom of the crushing chamber and play a role in grading and screening. The gap size of the grate bars is directly related to the product particle size and can be customized according to the use of recycled aggregates (such as recycled concrete aggregate, road base aggregate). The driving device consists of a motor, coupling, and reducer, providing stable power for the high-speed rotation of the rotor. Some large impact crushers are also equipped with a hydraulic starting device to reduce the load during equipment startup and protect the motor and transmission components. The frame adopts a welded steel structure with sufficient strength and rigidity to withstand the huge impact force generated by material impact, ensuring stable operation of the equipment.

The complete process of crushing construction waste with an impact crusher can be divided into five stages: feeding and pre-treatment, crushing and processing, grading and screening, product collection, and equipment maintenance. These stages work closely together to form a closed-loop resource utilization system. The first stage is feed pretreatment, a crucial step in ensuring a smooth crushing process and equipment safety. Construction waste has a complex composition; in addition to crushable materials such as concrete blocks and bricks, it may also contain impurities such as rebar, wood, plastic, and fabric. If these materials are fed directly into the impact crusher, it will not only affect crushing efficiency but may also cause equipment jamming and damage. Therefore, impurities must be removed through a pretreatment process before feeding: firstly, rebar, wood, plastic, and other debris are separated through manual sorting or intelligent sorting equipment (such as magnetic separators and air separators). The rebar can be recycled, while wood and plastic can be incinerated for power generation or further sorted and recycled; secondly, oversized construction waste (such as large concrete components and thick bricks) is initially crushed using coarse crushing equipment such as jaw crushers to control the material particle size to below 300-500mm, preventing material blockage in the crushing chamber or damage to the hammer plates; finally, the pretreated material is evenly conveyed to the feed opening of the impact crusher through a feeder, ensuring that the material is evenly stressed after entering the crushing chamber, avoiding excessive local load that affects the stable operation of the equipment.

The second stage is the core crushing process. The pretreated construction waste enters the crushing chamber of the impact crusher through the feed opening. The motor drives the rotor to rotate at high speed through a reducer. The hammer plates on the rotor impact the material at high speed, completing the initial impact crushing. The impacted material gains kinetic energy and is thrown towards the impact plate above the crushing chamber, where it collides violently with the impact plate, resulting in secondary impact crushing; the rebounded material collides with the subsequently entering material, generating "self-impact crushing," further refining the particles; the material that has undergone multiple impact crushing falls to the bottom of the crushing chamber, where it is ground and shaped in the gap between the grate bars and the hammer plates and impact plates. At the same time, the grate bars classify the material; material that meets the particle size requirements is discharged from the crushing chamber through the gaps in the grate bars, while unqualified coarse material remains in the crushing chamber to continue to be impacted and ground, or is returned to the crushing chamber for re-crushing through a circulating conveying device. During the crushing process, operators need to monitor the equipment's operating status in real time through monitoring devices (such as motor current, crushing chamber pressure, and material discharge speed). They must also flexibly adjust the rotor speed, the gap between the impact plate and the rotor, and the grate gap based on material characteristics and product particle size requirements to ensure stable crushing efficiency and product quality. For example, when crushing high-hardness concrete blocks, the rotor speed can be appropriately increased and the impact plate gap reduced to enhance the impact crushing effect; when crushing lower-hardness bricks and stones, the speed can be reduced and the gap increased to improve processing efficiency.

The third stage is classification and screening. The material discharged from the impact crusher may still contain a small amount of coarse material that does not meet the particle size requirements, so classification and screening are necessary. Vibrating screens are typically used to classify the crushed material. Different screen mesh sizes are set according to the intended use of the recycled aggregate. Common classification standards are: 5-25mm particle size for recycled concrete aggregate, 25-40mm particle size for road base aggregate, and less than 5mm particle size for recycled mortar aggregate or roadbed filler. Through vibrating screen classification, the qualified recycled aggregate enters the corresponding collection bin, while the unqualified coarse material is returned to the impact crusher via a conveyor belt for re-crushing, forming a closed-loop process of "crushing-screening-re-crushing" to ensure the qualified rate of product particle size. Simultaneously, during the classification and screening process, a magnetic separator can be used again to separate any remaining small steel reinforcement fragments from the material, further improving the purity of the recycled aggregate.

The fourth stage is product collection and subsequent processing. The classified and screened recycled aggregate undergoes different subsequent treatments depending on its use: aggregate used for recycled concrete needs to be cleaned to remove surface dust and impurities, improving the bonding performance between the aggregate and cement; aggregate used for road sub-base can be directly stockpiled or undergo simple drying; fine recycled powder can be mixed with cement and admixtures to make recycled mortar or concrete admixtures. The collected recycled aggregate should be properly stored to prevent contamination by rainwater during open-air storage, and dust control measures should be implemented to reduce dust pollution. Through this stage of processing, construction waste is transformed into high-value recycled building materials, achieving resource recycling and significantly reducing the environmental pressure of construction waste landfill.

The fifth stage is equipment maintenance and upkeep. During the crushing of construction waste, components such as the hammer plates, impact plates, and grate bars of the impact crusher are subjected to strong impact and wear. If not maintained promptly, this will affect equipment performance and service life. Therefore, a comprehensive equipment maintenance system needs to be established: after operation, promptly clean the residual materials in the crushing chamber to prevent material clumping and blockage; regularly check the wear of the hammer plates, impact plates, and grate bars, and replace them promptly if wear exceeds the limit or damage occurs; check the operating status of the rotor main shaft to ensure that the main shaft is not deformed and the bearings are not loose, and regularly add lubricating oil to ensure smooth rotor operation; check the motor, reducer, and other components of the drive device to ensure stable circuit connections and sufficient oil, and promptly address abnormal noises and vibrations. In addition, operators need to receive professional training to standardize operating procedures and avoid equipment failures caused by improper operation, ensuring long-term stable and efficient operation of the equipment.

The effectiveness of the impact crusher in crushing construction waste is affected by many factors, mainly including material characteristics, equipment parameters, and operating conditions. In terms of material characteristics, the hardness, moisture content, and impurity content of construction waste are the core influencing factors. When the hardness of materials such as concrete blocks and bricks is high, it will exacerbate the wear of the hammer plates and impact plates, reducing crushing efficiency; when the moisture content of the material is too high (exceeding 15%), it is easy to stick and block in the crushing chamber and grate bars, affecting material conveying and classification; when the impurity content (such as rebar and wood) is too high, it will increase the difficulty of pretreatment and reduce the stability of equipment operation. In terms of equipment parameters, rotor speed, impact plate gap, grate gap, and hammer type are key influencing factors: higher rotor speed leads to greater impact kinetic energy of the hammers and a higher crushing ratio, but also increases energy consumption and wear; a smaller impact plate gap results in finer product particle size, but increases crushing resistance and may reduce processing efficiency; the grate gap directly determines the maximum particle size of the product and needs to be precisely adjusted according to the intended use of the recycled aggregate; the material and shape of the hammers must match the hardness of the material: high-manganese steel hammers are suitable for crushing medium-hard materials, while high-chromium cast iron hammers are suitable for crushing hard materials. In terms of operating conditions, feeding speed and feeding uniformity are crucial: excessively fast feeding speed can lead to material accumulation in the crushing chamber, excessive load, and even equipment jamming; excessively slow feeding speed will reduce equipment processing efficiency; uneven feeding will cause local load fluctuations, affecting the crushing effect and equipment lifespan.

To further improve the efficiency of crushing construction waste with impact crushers and reduce operating costs, a series of optimization strategies can be adopted. In terms of equipment improvement, intelligent upgrades and modifications can be implemented, including installing an Internet of Things monitoring system to collect equipment operating parameters (such as speed, load, temperature, and wear) and material characteristics data in real time. Big data analysis can then be used to automatically optimize and adjust parameters, improving the intelligent operation level of the equipment; the material of the hammers and impact plates can be improved by using composite wear-resistant materials (such as a composite of high-manganese steel and high-chromium cast iron) to improve component wear resistance and extend service life; the crushing chamber structure can be optimized by adopting a "multi-chamber" design to increase the number of material impacts, improving the crushing ratio and product shaping effect. In terms of process optimization, a multi-stage crushing process of "coarse crushing - medium crushing - fine crushing" can be established. Based on the original particle size of the construction waste and the final product requirements, jaw crushers (coarse crushing), impact crushers (medium/fine crushing), and other equipment can be rationally combined to improve overall processing efficiency; a drying device can be added in the pretreatment stage to reduce the moisture content of the material and prevent clogging; a closed crushing workshop and a negative pressure dust removal system can be used to reduce dust pollution and improve the working environment. In terms of operational management, a material classification and pre-treatment system has been established to classify and crush construction waste of different types and hardness levels, improving crushing efficiency and product quality. A scientific equipment maintenance plan has been developed, with regular preventive maintenance to reduce downtime. Operator skills training has been strengthened to improve their parameter adjustment and troubleshooting capabilities, ensuring stable equipment operation.

The impact crusher, utilizing a multi-stage crushing principle of "impact-rebound-self-impact-grinding," efficiently crushes construction waste into high-quality recycled aggregates, making it a core piece of equipment in the resource utilization of construction waste. The crushing process involves five key stages: material pre-treatment, crushing, classification and screening, product collection, and equipment maintenance. The coordinated operation of each stage is crucial to ensuring processing efficiency and product quality. In practical applications, the influence of material characteristics, equipment parameters, and operating conditions must be fully considered. Through strategies such as intelligent equipment upgrades, process optimization, and scientific management, crushing efficiency can be further improved and operating costs reduced. With the continuous improvement of my country's construction waste resource utilization policies and the sustained growth of the recycled building materials market, impact crushers will play an even more important role in the field of construction waste treatment, providing strong support for promoting the reduction, resource utilization, and harmless disposal of construction waste, and achieving green and low-carbon development.

Save Time! Get A Detailed Quotation Quickly.