With the acceleration of urbanization, my country's annual construction waste production has exceeded 3 billion tons. Crushing, as the core process of construction waste resource utilization, directly determines the quality and utilization rate of recycled aggregates. The rational selection of crushing equipment is a key prerequisite for achieving efficient disposal. Construction waste has a complex composition, including concrete blocks, bricks, scrap steel bars, plastics, and other materials. Different materials vary significantly in hardness and particle size, requiring different types of crushing equipment. Currently, the mainstream construction waste crushing equipment in the industry can be divided into two main categories: stationary crushing equipment and mobile crushing equipment. Each category contains various sub-models, each with unique structural characteristics and applicable scenarios, collectively forming a comprehensive crushing and processing system covering the entire process and adapting to diverse needs, facilitating the efficient transformation of construction waste from "waste" to "resource."

Stationary crushing equipment is the core equipment of centralized construction waste disposal centers. With its advantages of large processing capacity, high stability, and low energy consumption, it is widely used in large-scale, routine construction waste crushing operations. It is usually used in conjunction with screening and sorting equipment to form a standardized production line. These types of equipment need to be fixedly installed at a pre-designated site, requiring initial site planning and infrastructure construction. They are suitable for long-term, stable operation projects. Common sub-types mainly include jaw crushers, impact crushers, and cone crushers.

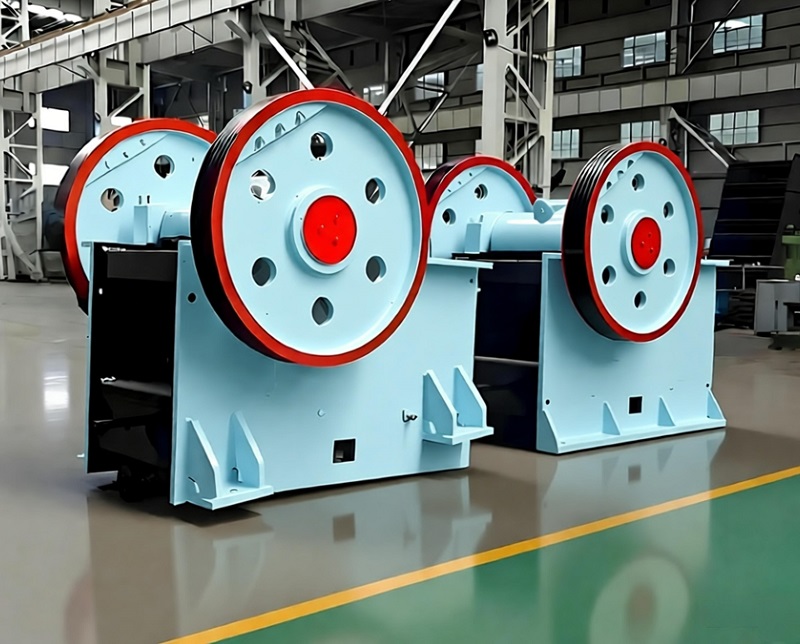

Jaw crushers, as the "primary crushing core" of a stationary crushing production line, are the first stage in the crushing of construction waste, primarily used to process large, hard construction waste materials. They employ the principle of compression crushing, using the relative movement of the moving and fixed jaws to crush large concrete blocks, bricks, and waste wall materials with particle sizes of 1-2 meters into primary crushed materials of 100-300mm, laying the foundation for subsequent medium and fine crushing operations. This equipment has a stable structure, a large crushing ratio, a deep crushing chamber without dead zones, effectively preventing material blockage, and a failure rate typically below 5%, resulting in relatively low maintenance costs. It boasts extremely high technological maturity and is suitable for crushing construction waste of various hardnesses, efficiently processing everything from large pieces of waste concrete generated at demolition sites to asphalt blocks from road repairs. Currently, mainstream jaw crushers have a processing capacity of 50-500 t/h, meeting the production needs of processing centers of different sizes, and are one of the indispensable core equipment in stationary crushing production lines.

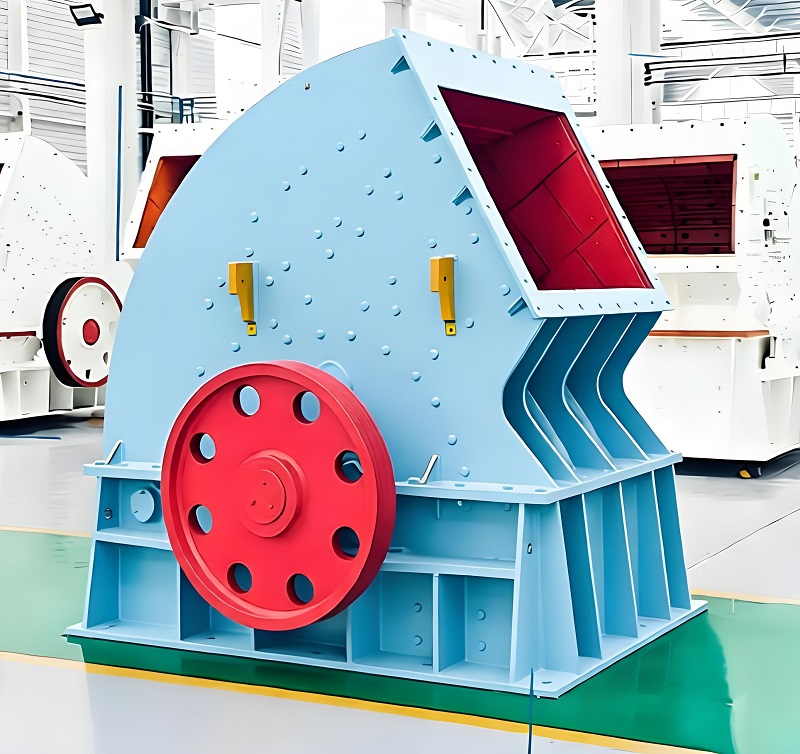

Impact crushers are mainly used for medium and fine crushing of construction waste. They take the primary crushed material from jaw crushers and further crush it to a particle size that meets the standards for recycled aggregates (usually 0-30mm), making them key equipment for improving the particle shape quality of recycled aggregates. Their core working principle is to use high-speed rotating rotor hammers to impact and crush the material. After entering the crushing chamber, the material is impacted at high speed by the hammers against the impact liner. Through multiple collisions and friction, it ultimately forms cubic particles with uniform shape and low needle-like and flaky content, making it very suitable for the production of recycled building materials with high requirements for aggregate particle shape, such as recycled concrete and recycled mortar. This equipment has a large crushing ratio, adjustable finished particle size, and selective crushing function, which can effectively separate light materials from construction waste while causing less damage to metal materials such as waste steel bars, facilitating subsequent sorting and recycling. Wenzhou's first construction waste and bulky waste disposal center has introduced impact crushers, which, in conjunction with other equipment, precisely separate various components from construction waste, achieving efficient resource recovery. Mainstream impact crushers have a processing capacity of 30-300 tons per hour and are widely used in large and medium-sized construction waste disposal centers. They are often used in conjunction with jaw crushers to form a complete fixed crushing process of "coarse crushing + medium and fine crushing."

Cone crushers are high-precision fine crushing equipment, mainly used in construction waste crushing scenarios with high requirements for finished product particle size, such as producing high-quality construction sand and high-end recycled aggregates. They employ the principle of layered crushing, using the squeezing and shearing action of the moving and fixed cones to finely crush materials. The crushing process is stable, the finished product particle size is uniform, and energy consumption is low. They can effectively control the output particle size, meeting the personalized needs of different downstream industries. Compared to impact crushers, cone crushers have stronger wear resistance and are suitable for processing construction waste with higher hardness, such as waste granite and waste marble. They also have the advantages of stable operation, low noise, and low dust, meeting modern environmental protection production requirements. In large-scale construction waste recycling projects, cone crushers are often used as the third-stage crushing equipment, following the output of impact crushers to further optimize the quality of recycled aggregates and enhance their resource utilization value. Their processing capacity can reach 50-400 t/h, adapting to large-scale, high-quality crushing production needs. Their technological maturity and stability are among the industry's leading levels.

Mobile crushing equipment is the core equipment for addressing the scattered and temporary crushing needs of construction waste. With its advantages of mobility, flexibility, no need for fixed sites, and on-site operation, it overcomes the limitations of stationary crushing equipment and is widely used in demolition sites, road repairs, and small-scale construction waste disposal scenarios. These types of equipment integrate crushing, feeding, and screening functions into one unit. With a vehicle-mounted design, they can be flexibly moved to the work site without prior site construction. Commissioning can be completed and the equipment put into use within 1-2 months, significantly reducing the transportation costs of construction waste and minimizing dust and noise pollution during transport. This achieves an environmentally friendly "on-site crushing and utilization" disposal model, making it a hot development trend in the construction waste crushing field in recent years. Common sub-models include mobile jaw crushers, mobile impact crushers, and mobile composite crushers, with processing capacities ranging from 50-500 t/h. Investment costs are relatively moderate, making them suitable for temporary disposal and small- to medium-scale disposal projects.

Mobile jaw crushers are the most widely used type of mobile crushing equipment. They integrate a jaw crusher with a feeder, conveyor, and screening machine on a single frame, allowing for flexible movement to demolition sites and construction sites to directly process large pieces of construction waste. This eliminates the need to transport materials to a centralized disposal center, significantly improving disposal efficiency. This equipment possesses the same crushing advantages as a stationary jaw crusher, featuring a robust structure, high crushing ratio, and the ability to process various large pieces of construction waste. It also boasts flexibility and convenience, allowing for adjustments to the operating position and crushing parameters based on site space and material type, adapting to complex working environments. For remote areas, small-scale demolition projects, and other scenarios unsuitable for stationary crushing production lines, mobile jaw crushers can independently complete crushing operations. The primary crushed material produced can be directly used for roadbeds, foundation backfilling, etc., achieving on-site resource utilization and effectively reducing disposal costs. Some mobile jaw crushers also support remote control operation, further enhancing operational safety and convenience.

Mobile impact crushers integrate an impact crusher onto a vehicle-mounted platform, primarily used for on-site medium and fine crushing of construction waste. They can handle primary crushed material from mobile jaw crushers or directly process smaller-sized construction waste, such as renovation waste and small concrete blocks. It possesses all the advantages of an impact crusher, producing high-quality, adjustable-size finished products. Its mobility allows it to move flexibly with the work site, making it suitable for the fragmented crushing needs of construction waste, such as in urban demolition and road renovation. Shandong Road & Bridge has equipped itself with a mobile impact crusher. This equipment can handle large feed sizes (0-800mm), has a high output (200-500 tons/hour), and an annual production capacity of 800,000-1.5 million tons. It can be used for tunnel muck treatment and the reuse of excavated rock. After maintenance, it can maintain high-efficiency operation for a long time, providing support for innovation and efficiency in engineering projects. Furthermore, mobile impact crushers can be combined with screening equipment to achieve integrated crushing and screening operations, directly producing recycled aggregates of different specifications, significantly improving processing efficiency and reducing equipment investment costs.

In addition to the above mainstream models, there are also some specialized crushing equipment in the construction waste crushing field, such as hammer crushers and twin-shaft shredders, adapted to specific types of construction waste crushing needs. Hammer crushers, equipped with rebar cutting devices, prevent main unit blockage and are suitable for processing construction waste with relatively little rebar, but machine wear is relatively severe. Dual-shaft shredders utilize staggered blades and teeth to shear and shred materials, primarily suitable for crushing lightweight materials such as plastic packaging drums and rubber tires, thus providing comprehensive coverage for construction waste crushing.

With increasingly stringent environmental policies and rising demand for the resource utilization of construction waste, crushing equipment is undergoing iterative upgrades towards intelligence, environmental friendliness, and modularity. New crushing equipment is generally equipped with dust collection systems and noise reduction devices, effectively controlling dust and noise pollution during operation and meeting green production requirements. Simultaneously, the application of intelligent control systems enables remote monitoring, parameter adjustment, and fault warning functions, significantly reducing manual labor intensity and improving operational efficiency and equipment stability. Deqing County Difida Building Materials Co., Ltd. has adopted a fully enclosed resource recycling technology, combining advanced crushing equipment with a spray dust suppression system to achieve dust-free processing, with an annual processing capacity of 600,000 tons of construction waste and a resource utilization rate exceeding 88%, achieving a win-win situation for environmental protection and economic benefits.

Construction waste crushing equipment comes in a wide variety of types and functions. Stationary crushing equipment focuses on large-scale, routine processing, while mobile crushing equipment adapts to decentralized, temporary needs. These various sub-types work together in combination to form a comprehensive construction waste crushing system covering all scenarios and processes. The rational selection of crushing equipment can not only improve the efficiency of construction waste crushing and the quality of recycled aggregates, but also reduce disposal costs and environmental pollution, promoting the high-quality development of the construction waste resource utilization industry, contributing to the achievement of "dual carbon" goals and the construction of green cities, and ensuring that every piece of construction waste realizes its maximum resource value.

Save Time! Get A Detailed Quotation Quickly.