In the waste resource utilization industry chain, the efficiency of the screening process directly determines the value of resource recovery. However, the heterogeneity and irregularity of raw waste often create a bottleneck in screening. As the core pre-processing equipment, the twin-shaft shredder utilizes shearing and extrusion to crush and provide standardized material for subsequent screening. It not only solves traditional challenges such as bulk material blockage and component adhesion, but also collaborates with multiple devices to build a highly efficient sorting system. This article focuses on its core role in pre-processing adaptation, improving system efficiency, and synergizing the entire supply chain. It analyzes the technology's value and development path, providing a reference for upgrading waste screening technology.

1. Pre-processing Adaptation: Overcoming the Complexity of Pre-Screening Materials

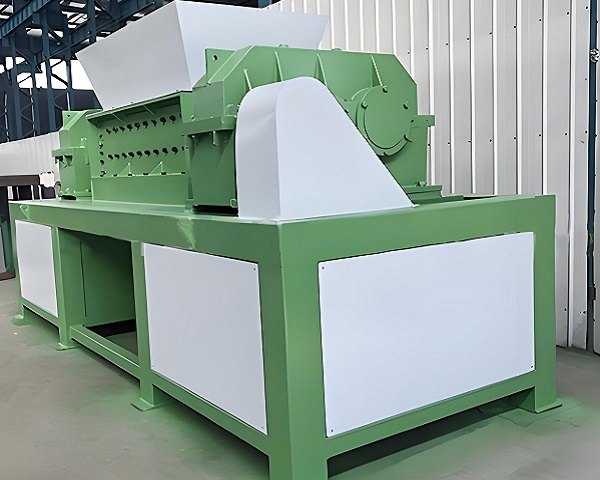

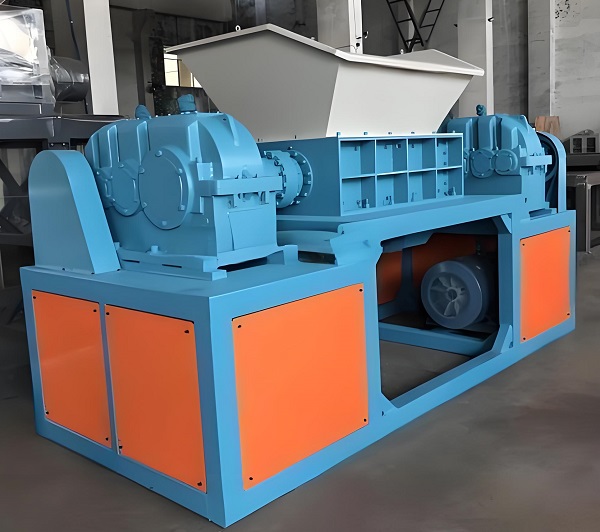

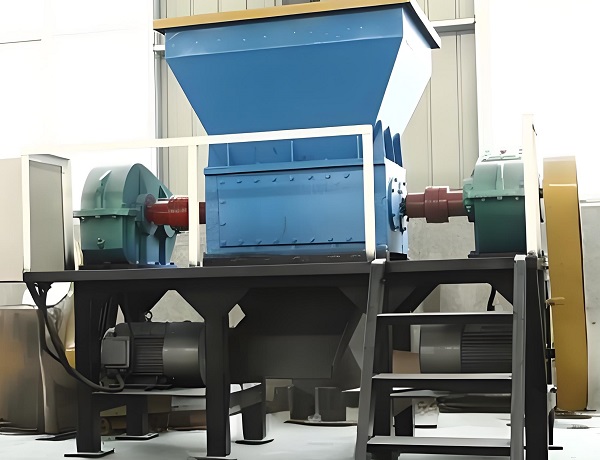

As the "front-end pre-processing core" of the waste screening system, the twin-shaft shredder's primary function is to transform the chaotic and disordered raw waste into standardized material suitable for subsequent screening, eliminating screening obstacles at the source. It uses two counter-rotating blade shafts to shear and compress each other, capable of processing a wide range of waste sizes. The maximum feed size is 1500mm, and the output size can be adjusted to a uniform granularity of 20-100mm by adjusting the blade shaft gap. This effectively solves the problem of large pieces of material clogging the equipment in traditional screening systems.

In the treatment of domestic waste, this equipment effectively removes plastic packaging from perishable waste. A food waste treatment plant in Zhejiang Province uses a dual-shaft shredder in conjunction with a drum screen. The shredder tears through plastic bags and breaks up food waste clumps, increasing the inorganic separation efficiency of the subsequent screening process by 40% and achieving an organic purity of 92%. For construction waste, the dual-shaft shredder can reduce mixed materials such as concrete blocks and waste wood to a uniform particle size. In a construction waste project in Zhengzhou, Henan, this pre-treatment device increased the aggregate screening efficiency of the subsequent vibrating screen from 55% to 88%, with the impurity content of recycled aggregate below 2%. For high-value waste like electronic waste, the precise shredding of a twin-shaft shredder is crucial. The Qichun scrap appliance dismantling line in Hubei Province uses a combination of a twin-shaft shredder and a vertical crusher to break refrigerator casings into uniform particles, paving the way for downstream magnetic and eddy current separation. This results in an iron separation rate of 99% and a plastic separation rate exceeding 97%, representing a recovery rate improvement of over 30 percentage points compared to a process without pretreatment.

2. Efficiency Improvement: Enhanced Sorting Performance of the Screening System

By optimizing the physical form of the material, the twin-shaft shredder fundamentally improves the operating efficiency and sorting accuracy of the entire screening system. Its core value lies in its homogenization and disaggregation effects. Homogenization ensures a more even distribution of the material within the screening equipment, preventing local overload. Disaggregation separates different components of the composite material, facilitating precise sorting. Regarding material homogenization, the twin-shaft shredder's variable frequency feed system adjusts the processing speed based on the waste composition. A single machine can process 10-50 tons/hour, with the standard deviation of the crushed material particle size kept within 15mm. Data from a Shandong municipal waste landfill shows that after introducing this equipment, the drum screen's processing capacity increased from 25 tons/hour to 42 tons/hour, and the number of equipment blockages and downtimes decreased from 3-5 times per day to 0-1 times.

The dissociation effect is significant in sorting mixed waste. For mixed plastics, paper, and metal waste, the shearing action of the twin-shaft shredder breaks down the adhesions between the components. At a resource recycling center in Jiangsu, the separation purity of light materials in the air separator increased from 68% to 89%, and the recovery rate of non-ferrous metals in the subsequent eddy current separation increased by 22%. In the agricultural waste sector, this equipment can shred and disintegrate the composite of straw and soil, reducing the impurity content of the screened straw to less than 5%, meeting the raw material requirements for biomass power generation.

In addition, the dual-shaft shredder's low energy consumption further enhances the overall system efficiency. The new equipment, which utilizes a rare earth permanent magnet motor, reduces unit shredding energy consumption by 27% compared to traditional models. Operational data from a waste treatment plant in Zhejiang Province shows that after introducing this equipment, the unit waste treatment energy consumption of the entire screening system decreased from 8.2 kWh/ton to 5.6 kWh/ton, saving over 120,000 kWh of electricity annually.

3. System Synergy: Building a Full-Chain Resource Recovery System

The dual-shaft shredder is not an isolated device, but rather a synergistic hub in the entire waste screening and resource recovery chain. By matching the processes of various sorting equipment, it maximizes the value of resource recovery. In the integrated "shredding-screening-sorting" process, it plays a key role in connecting the front-end waste reception and providing compatible materials for the back-end multi-technique sorting. In integrated solid waste treatment systems, the synergy between twin-shaft shredders and other equipment, including air separation, magnetic separation, and optical sorting, has become mainstream. Beijing's first Huainan solid waste project utilizes a "twin-shaft shredder + magnetic separation + air separation + eddy current separation" process chain. The shredder first crushes mixed waste to a particle size of 30mm. After magnetic separation removes ferromagnetic materials, air separation separates lightweight plastics. Finally, eddy current separation recovers non-ferrous metals. The overall system resource recovery rate exceeds 90%, a 25% increase over traditional processes.

The twin-shaft shredder can be flexibly adapted to specialized screening systems for different waste types. In the treatment of renovation waste, it is combined with a vibrating screen and an air separator. The crushed material is screened to remove sand and gravel, and air separation is used to separate light dust, resulting in a 98% purity for recycled plastics. In the recycling of used tires, a double-shaft shredder breaks the tires into rubber chunks smaller than 50mm. Subsequent fine screening and magnetic separation enable efficient separation of rubber, steel wire, and fiber, achieving a resource utilization rate of over 95%.

This synergy is also reflected in policy adaptation. With the advancement of "Zero Waste City" construction, a domestic waste recycling rate of over 35% is required. As a core pre-treatment device, double-shaft shredders have become standard equipment for projects meeting this standard. By 2024, the deployment rate of this equipment in new domestic waste screening projects reached 92%, a 58 percentage point increase from 2020.

4. Existing Challenges and Optimization Directions

Despite their significant role, twin-shaft shredders still face bottlenecks in waste screening applications: For high-moisture materials (moisture content exceeding 20%), the blades are prone to material adhesion, resulting in a 30% reduction in shredding efficiency. When processing waste containing hard metals, the blades suffer severe wear, shortening the replacement cycle to 1-2 months and increasing maintenance costs. Furthermore, small and medium-sized enterprises rely on imported core components, with the procurement cost of the blades and drive system accounting for 45% of the total equipment price, hindering the widespread adoption of this technology.

Future optimization directions are clear: On the technical level, research and development of wear-resistant and corrosion-resistant blade materials are underway. Tungsten carbide coatings can extend blade life to over 6 months. Intelligent upgrades are underway, integrating infrared detection and AI algorithms to automatically identify foreign objects and provide shutdown protection. The intelligent twin-shaft shredder in the Hubei Qichun project has achieved a 98% accuracy rate in metal foreign object recognition and reduced downtime by 80%. On the process level, the development of an integrated "shredding-drying-screening" system is addressing the challenges of handling high-moisture materials.

Dual-shaft shredders, through their three core functions of pre-processing adaptation, efficiency improvement, and system synergy, have become an irreplaceable key piece of equipment in the waste screening industry chain. Their technological advancements are directly driving the transformation of waste resource utilization from "extensive recycling" to "precise sorting." With the in-depth application of material innovation and intelligent technologies, this equipment will further overcome the bottleneck of adaptability to operating conditions. This will provide more efficient front-end support for waste screening systems in the pursuit of "zero-waste cities" and the "dual carbon" goals, contributing to the value upgrade of the circular economy industry chain.

Save Time! Get A Detailed Quotation Quickly.