Preface: The disc screen, also known as the disc roller screen or mud-stone separator, is an efficient material sorting equipment, especially suitable for the treatment of various types of solid waste such as domestic waste, construction and decoration waste, stale waste, kitchen waste, and coal in coal mines. Through the rolling of the disc, the disc screen can effectively separate materials of different sizes and shapes, and its characteristics and advantages stand out among many screening equipment. The following is a detailed description of the characteristics and advantages of the disc screen.

A. Characteristics of the disc screen

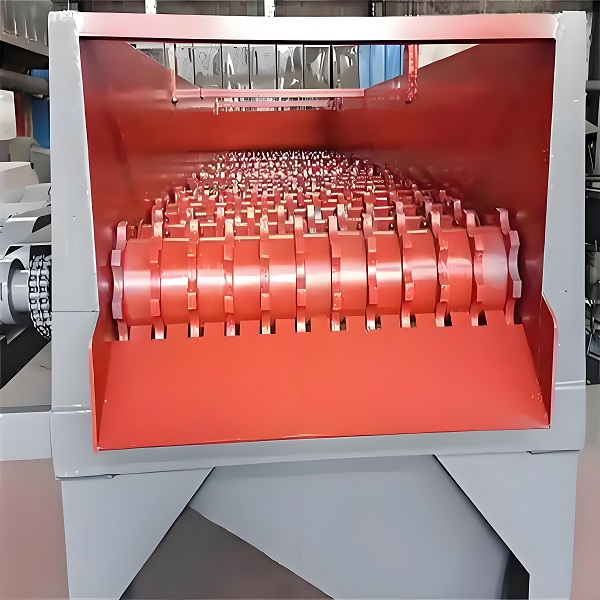

Disk Screen

1. Ingenious structural design

Modular design: The disc screen adopts a modular design, which means that the appropriate number of modules can be selected according to the actual needs of the customer. This design not only facilitates the maintenance and structural adjustment of the equipment, but also reduces the maintenance cost and improves the flexibility of the equipment.

Sturdy and durable: The box of the disc screen is welded with profiles, and the lining plate is made of wear-resistant steel plate, which makes the overall equipment sturdy and durable, suitable for long-term continuous operation. At the same time, the screen plate is made of wear-resistant materials (such as 13 manganese material), which further extends the service life of the equipment.

2. Flexible adjustment

Adjustable screen angle: The inclination angle of the screen plate and the box of the disc screen can be adjusted as a whole through the hydraulic system, and the adjustment angle is convenient and has a wide range. This enables the disc screen to adapt to the screening needs of a variety of materials and improves the versatility of the equipment.

Adjustable disc gap: By adjusting the gap between the discs, the disc screen can effectively separate materials with large size differences. This flexibility makes the disc screen more efficient and accurate when handling different types of garbage.

3. Stable operation

Low noise design: The disc screen uses multi-axis rotation to push the material forward. This design not only reduces the noise level of the equipment, but also improves the operating stability of the equipment.

Overload protection device: The disc screen is equipped with an overload protection device. When the roller is stuck, it can automatically cut off the power supply of the motor to achieve the purpose of self-protection, further ensuring the stable operation of the equipment.

4. Self-cleaning function

Dynamic sieve hole design: The dynamic sieve hole of the disc screen has a self-cleaning function, which can effectively prevent the sieve hole from being blocked. This design not only improves the screening efficiency of the equipment, but also reduces the frequency and difficulty of manual cleaning.

Cleaning device: The screen body is equipped with a cleaning device to further ensure the unobstructed flow of the screen holes.

5. Intelligent control

Frequency conversion control: The reducer of the disc screen adopts frequency conversion control, which reduces the energy consumption of the equipment and improves safety. At the same time, frequency conversion control also makes the processing capacity of the equipment adjustable, further meeting the needs of different customers.

Modular eccentric shaft design: The modular eccentric shaft design is adopted, with good performance and low maintenance cost. This design not only improves the screening efficiency of the equipment, but also reduces the maintenance cost.

B. Advantages of disc screen

Disk Screen

1. Efficient screening

Large processing capacity: The processing capacity of the disc screen is 4 times that of the traditional drum screen of the same volume, and the screening efficiency is 2 times that of the drum screen. This makes the disc screen more efficient when processing large amounts of garbage and can complete the task faster.

High screening accuracy: By adjusting the gap between the discs and the angle of the screen plate, the disc screen can accurately separate materials of different sizes and shapes. This high-precision screening not only improves the resource utilization rate of garbage, but also reduces the difficulty and cost of subsequent processing.

2. Energy saving and environmental protection

Low energy consumption: The disc screen adopts frequency conversion control, which can adjust the operating power of the equipment according to actual needs, thereby reducing energy consumption. This is not only conducive to saving resources, but also reduces carbon emissions, which is in line with the current development trend of green environmental protection.

Dust and noise prevention: The cover of the disc screen adopts a sealed design, which effectively prevents the leakage of dust and noise. This design not only protects the health of the operator, but also reduces environmental pollution.

3. Easy maintenance

Modular design: The modular design of the disc screen makes the maintenance and structural adjustment of the equipment simpler and more convenient. When a module fails, it can be quickly replaced or repaired without shutting down the entire equipment. This greatly improves the reliability and availability of the equipment.

Low maintenance cost: Because the disc screen adopts wear-resistant materials and modular design, its maintenance cost is relatively low. This reduces the customer's operating costs and improves the economy of the equipment.

4. Wide application

Strong adaptability: The disc screen is suitable for the screening and processing of a variety of materials, including domestic waste, construction and decoration waste, stale waste, kitchen waste, and coal in coal mines. This wide range of applicability makes the disc screen have a wide range of application prospects in various fields.

Promote the development of environmental protection: The disc screen's efficient screening and energy-saving and environmental protection characteristics make it play an important role in the field of solid waste treatment. Through technological innovation and optimized design, the disc screen provides a more efficient and reliable solution for solid waste treatment, and promotes the development of environmental protection.

C. Application cases of disc screens in different fields

Disk Screen

1. Domestic waste treatment

In the field of domestic waste treatment, the disc screen can effectively separate garbage of different sizes and shapes, which provides convenience for subsequent classification and treatment. At the same time, the efficient screening and energy-saving and environmental protection characteristics of the disc screen also make it have a wide range of application prospects in the field of domestic waste treatment.

2. Construction and decoration waste treatment

In the field of construction and decoration waste treatment, the disc screen can effectively separate bricks, concrete blocks, wood and other materials, which provides convenience for subsequent resource utilization. At the same time, the durability and easy maintenance of the disc screen also make it have significant advantages in the field of construction and decoration waste treatment.

3. Coal Mine Screening

In the field of coal mine screening, the disc screen can effectively separate materials such as lump coal, coal powder, and coal gangue, which provides convenience for subsequent coal processing and utilization. At the same time, the low noise design and overload protection device of the disc screen also make it have broad application prospects in the field of coal mine screening.

pS: The disc screen has emerged in the field of solid waste treatment with its high-efficiency screening, energy saving and environmental protection, easy maintenance and wide application. With the continuous advancement of technology and the continuous expansion of the market, the application prospects of the disc screen will be broader. In the future, the disc screen will play an important role in more fields and contribute more to the development of environmental protection. At the same time, we also look forward to more breakthroughs in technological innovation and optimized design of the disc screen, and provide more efficient and reliable solutions for solid waste treatment. As an efficient material sorting equipment, the disc screen has significant advantages and broad application prospects in the field of solid waste treatment. By deeply understanding the characteristics and advantages of the disc screen, we can better use this equipment to contribute to the environmental protection cause.

Save Time! Get A Detailed Quotation Quickly.