Introduction: In the garbage disposal system, garbage screening is a key link to achieve effective garbage treatment and resource recycling. With the acceleration of urbanization, the amount of garbage is increasing day by day and the composition is becoming more and more complex, and traditional treatment methods face huge challenges. As an important pre-treatment equipment, the shredder plays an indispensable role in garbage screening with its unique working principle and diversified application scenarios.

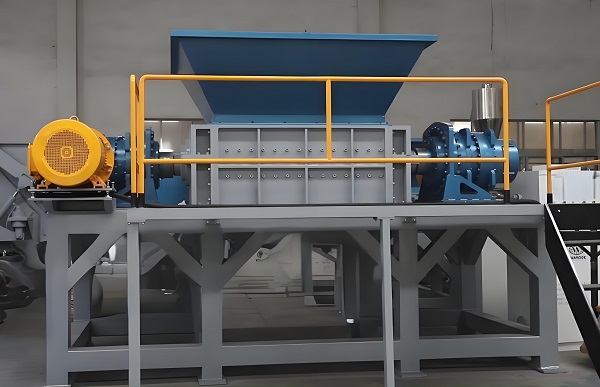

Shredder

1. Working principle and structure of the shredder

The shredder mainly crushes the garbage through the rotation and shearing action of the cutter. Its core component is the cutter made of high-strength alloy steel, which is installed on the rotating spindle and usually arranged in a staggered manner. When the motor drives the spindle to rotate at high speed, the cutter rotates at high speed, like a sharp pair of scissors, to shear, tear and squeeze the garbage entering the crushing chamber. Different types of shredders have different cutter shapes and arrangements, such as claw knife type, flat knife type, etc., to adapt to garbage with different characteristics.

The structure of the shredder generally includes the feed port, crushing chamber, cutter, transmission system, motor and discharge port. The feed port is designed to be suitable for the shape and size of garbage input to ensure that the garbage can enter the crushing chamber smoothly. The crushing chamber is made of high-strength wear-resistant materials to prevent the cutter from causing excessive wear to the chamber during the crushing process. The transmission system is responsible for transmitting the power of the motor to the spindle to ensure that the cutter rotates stably and at high speed. The motor is the core of power supply. According to the specifications and processing capacity of the shredder, motors of different powers are selected. The discharge port is used to discharge the crushed garbage, usually connected to the subsequent screening equipment.

2. The pretreatment role of the shredder before garbage screening

Garbage often contains various large items, such as waste furniture, discarded electrical appliances, wood and metal components in construction waste, etc. These large pieces of garbage are huge in size, and directly entering the screening equipment will cause the equipment to be blocked and damaged, and it is difficult to achieve effective screening. The shredder can break these large pieces of garbage into smaller sizes, which is convenient for subsequent screening and processing. For example, when processing waste furniture, the shredder can break heavy wooden boards, metal frames, etc. into small pieces, so that they can pass through the feed port of the screening equipment smoothly, improving the efficiency of the entire garbage treatment process.

The composition of garbage is complex and diverse, and the physical properties of garbage of different components vary greatly. In the screening process, in order to achieve more efficient separation, the garbage needs to be crushed to a relatively uniform particle size. The shredder can crush the garbage into a suitable particle size range by adjusting the gap and rotation speed of the cutter. For example, for plastics, paper and fibers in mixed garbage, after being processed by the shredder, their sizes become closer. In the subsequent screening links such as air separation and screening, it is easier to separate them according to their density, shape and other characteristics, thereby improving the accuracy and purity of the screening.

Some entangled or sticky garbage, such as waste wires and cables, plastic bags, sludge, etc., are easy to entangle and clog the screen in the screening equipment, affecting the screening effect. The strong crushing action of the shredder can break up and crush these entangled and sticky garbage, reducing the risk of entanglement and clogging. Taking waste wires and cables as an example, the shredder can separate and crush the outer skin and the internal metal wire so that they are no longer entangled with each other, which is convenient for subsequent screening and recycling.

3. The processing effect of shredders on different types of garbage

Shredder

Municipal domestic garbage contains a large amount of recyclable materials, such as waste paper, plastic bottles, metal cans, etc. When processing these garbage, the shredder can break them into shapes and sizes that are easy to recycle. For waste paper, after being processed by the shredder, it becomes fragments, which is convenient for packaging and transportation, and improves the recycling efficiency of waste paper. After being shredded, the volume of plastic bottles is reduced, which is convenient for storage and subsequent plastic recycling processing. After metal cans are shredded, the surface area increases, which is more conducive to the recycling and refining of metals and improves the recycling rate of resources.

Construction waste contains a large amount of concrete blocks, bricks, wood and waste metals. The shredder can effectively crush these construction wastes of different materials. For concrete blocks and bricks, after being crushed by the shredder, they can be used as recycled aggregates for the production of recycled concrete, recycled bricks and other building materials. After being shredded, wood can be used for biomass power generation, making artificial boards, etc. After the waste metal is shredded, it is convenient to carry out classified recycling and remelting, realize the resource utilization of construction waste, reduce dependence on natural resources, and reduce the impact of construction waste on the environment.

The composition of industrial waste is more complex, and may contain various chemical wastes, rubber products, electronic waste, etc. When the shredder handles industrial waste, it is necessary to select appropriate knives and crushing processes according to the characteristics of different wastes. For rubber products, the shredder can break them into small pieces to facilitate the subsequent rubber recycling. Electronic waste contains a large amount of metal and plastic, and the shredder can perform preliminary crushing on them, which provides convenience for subsequent metal recycling and plastic separation. Through the effective crushing and screening of industrial waste, the reduction and resource utilization of industrial waste can be achieved, and the pollution of industrial production to the environment can be reduced.

5. Collaborative work of shredder and other garbage screening equipment

In the garbage treatment production line, the shredder is usually used in conjunction with screening equipment (such as vibrating screen, drum screen, etc.). After the shredder crushes the garbage, the crushed garbage is transported to the screening equipment through a conveyor belt. The screening equipment further screens the garbage according to different screen mesh apertures to separate garbage of different particle sizes. For example, the vibrating screen can screen out garbage of smaller particle sizes for subsequent landfill or incineration; while garbage of larger particle sizes can be returned to the shredder for re-shredding to ensure that the garbage is fully processed.

The wind separator uses the principle of aerodynamics to separate garbage according to the density difference of the garbage. The garbage shredded by the shredder can be separated from light garbage (such as paper, plastic film, etc.) and heavy garbage (such as metal, masonry, etc.) by the wind separator. In this process, the shredder provides the wind separator with garbage of suitable particle size, so that the wind separator can separate more effectively. At the same time, the garbage of different components separated by the wind separator can also be further screened and recycled.

The magnetic separator is mainly used to separate magnetic substances in garbage, such as iron, nickel and other metals. When the garbage shredded by the shredder passes through the magnetic separator, the magnetic substances can be effectively adsorbed and separated. The crushing action of the shredder fully exposes the magnetic material in the garbage, improving the separation efficiency of the magnetic separator. Through the coordinated work of the shredder and the magnetic separator, the metal resources in the garbage can be efficiently recovered and the pollution of metal to the environment can be reduced.

Shredder

6. Advantages and challenges of shredders in garbage screening

The shredder can crush garbage of various shapes and sizes into smaller particles, improve the fluidity and uniformity of the garbage, and enable subsequent screening equipment to work more efficiently. Compared with traditional manual crushing or simple mechanical crushing methods, the processing capacity of the shredder is greatly improved, which can meet the needs of large-scale garbage disposal. In some large garbage treatment plants, the shredder can process tens or even hundreds of tons of garbage per hour, significantly improving the efficiency of garbage treatment.

The garbage processed by the shredder has a more uniform particle size, which enables more accurate separation according to the physical properties of the garbage in the subsequent screening process. For example, in the screening process, it is easier to control the aperture of the screen and accurately separate garbage of different particle sizes; in the air selection process, garbage of different densities is also easier to distinguish and separate, thereby improving the accuracy of garbage screening and helping to improve the purity of resource recovery.

The application of shredders can achieve effective separation and recycling of recyclables in garbage, reduce the amount of landfill and incineration of garbage, and reduce pollution to the environment. At the same time, by recycling resources in garbage, such as metals, plastics, paper, etc., certain economic benefits can be created to achieve resource utilization and sustainable development of garbage disposal.

With the continuous development of garbage disposal technology, the performance requirements for shredders are getting higher and higher. On the one hand, it is necessary to improve the processing capacity and crushing efficiency of shredders to meet the growing demand for garbage disposal; on the other hand, it is necessary to improve the crushing accuracy and adaptability of shredders to handle more complex and diverse garbage. This requires that in the research and development and manufacturing process of shredders, the design of cutters should be continuously optimized, the transmission system and control system should be improved, and the overall performance of the equipment should be improved.

When crushing some special garbage (such as electronic waste and chemical waste containing hazardous substances), the shredder may face problems such as tool wear and equipment corrosion. The harmful substances in these garbage may damage the tools and equipment, shorten the service life of the equipment, and increase the maintenance cost of the equipment. At the same time, in the crushing process, corresponding protective measures need to be taken to prevent the leakage of harmful substances from causing harm to the environment and operators.

PS: The shredder plays an important role in garbage screening. By pre-treating the garbage and working with other screening equipment, it can improve the efficiency of garbage treatment and resource recycling. Despite some challenges, with the continuous advancement of technology, the application prospects of shredders in the field of garbage treatment will be broader, providing strong support for the reduction, resource utilization and harmless treatment of garbage.

Save Time! Get A Detailed Quotation Quickly.