Vibrating feeders, as a key pre-processing equipment in material handling systems, achieve uniform and continuous feeding of materials through vibration excitation. They are widely used in various industrial fields such as mining, building materials, metallurgy, and chemical engineering. Their core value lies in connecting raw material storage with subsequent processing stages, ensuring stable operation of the production line, improving equipment processing efficiency, and reducing energy consumption through precise control of the feeding rate. Compared with traditional feeding equipment, vibrating feeders have significant advantages such as good feeding uniformity, flexible adjustment, and adaptability to harsh working conditions, making them an indispensable key equipment in modern industrial production. This article will systematically explain the structural composition and technical characteristics of vibrating feeders, and deeply analyze their application scenarios in various industries, providing professional reference for equipment selection and efficient operation for relevant enterprises.

A. Structural Composition and Technical Characteristics of Vibrating Feeders

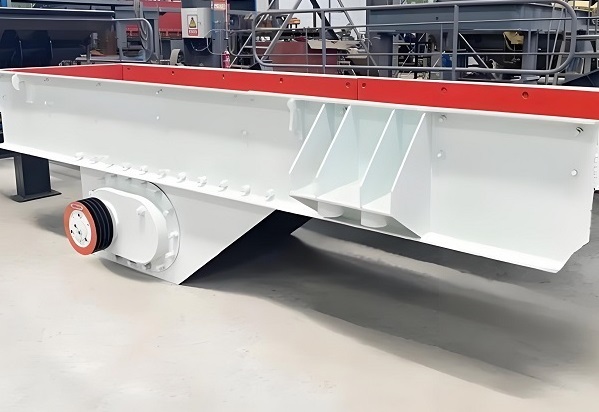

The structural design of vibrating feeders revolves around three core objectives: "stable vibration, precise feeding, and adaptability to complex materials." It mainly consists of five core parts: vibration source, feeding trough, support device, damping system, and control system. These components work together to achieve directional material transport through the conversion of vibration energy. Their structural characteristics directly determine the feeding performance and operational stability of the equipment.

1. Vibration Source: The core power of equipment operation

The vibration source is the key component that generates vibration in the vibrating feeder, directly affecting the feeding intensity, frequency, and uniformity. It is mainly divided into two types: electromagnetic vibration type and motor vibration type, each with its own technical characteristics:

a. Electromagnetic Vibration Source: It adopts the principle of electromagnetic excitation and consists of an electromagnet, armature, and spring plate. By controlling the on-off frequency of the electromagnet (usually 50Hz), it drives the armature and the feeding trough to perform high-frequency, small-amplitude vibrations. The vibration frequency is stable, and the adjustment accuracy is high. The feeding rate can be adjusted steplessly by adjusting the current size, making it suitable for scenarios requiring high feeding accuracy (such as automated production lines and precision screening systems). Its advantages include simple structure, low energy consumption, and low noise (operating noise ≤75dB), but the output amplitude is relatively small (usually 0.5-2mm), making it suitable for medium-sized or fine-grained materials. b. Motor Vibration Source: Based on a vibrating motor, this system generates centrifugal force through the rotation of eccentric blocks at both ends of the motor, creating periodic vibration. The motor speed (typically 960 r/min or 1450 r/min) determines the vibration frequency, and the angle of the eccentric blocks can adjust the amplitude (range 1-5 mm), thereby controlling the feeding rate. This type of vibration source has strong power and load capacity, and can adapt to the feeding needs of large-particle materials (particle size ≤ 300 mm) and high-humidity, high-viscosity materials. It is widely used in heavy industries such as mining and building materials. Its structure is robust, maintenance is simple, and its service life can reach more than 8000 hours. Furthermore, composite vibration trajectories can be achieved through dual-motor synchronous drive, improving material flow.

2. Feeding Trough: The material conveying component

The feeding trough is the core structure that directly carries and conveys the material. Its design needs to consider wear resistance, impact resistance, and material flow:

a. The trough material is usually Q235B steel plate or wear-resistant manganese steel (Mn13). For highly abrasive materials (such as ore and crushed stone), polyurethane or ceramic liners can be installed on the inner wall of the trough, increasing the service life by 3-5 times.

b. The trough structure comes in various forms, including linear, channel, and U-shaped: Linear troughs are suitable for horizontal or small-angle feeding (angle ≤ 15°), ensuring uniform and even material conveying; U-shaped troughs have a large volume and good anti-spillage effect, suitable for large-flow, lumpy material feeding; channel-shaped troughs guide material flow through side baffles, adapting to the inlet shape of equipment such as belt conveyors and crushers.

c. The trough and the vibration source are rigidly connected (e.g., bolted), with buffer pads at the connection points to reduce energy loss during vibration transmission and prevent structural deformation caused by material impact. 3. Support Device: The Load-Bearing Foundation for Stable Operation

The support device is used to fix the feeding trough and transmit vibration energy. It is mainly divided into two types: elastic support and rigid support:

a. Elastic Support: Using helical springs, rubber springs, or air springs as support elements, it has good shock absorption effects and can reduce the vibration impact on the foundation during equipment operation (vibration transmission rate ≤ 20%). The stiffness of the springs is precisely calculated based on the equipment weight and vibration parameters to ensure that the trough operates near the resonance frequency, improving vibration efficiency. This type of support is suitable for most industrial scenarios, especially production lines sensitive to foundation vibration.

c. Rigid Support: Directly fixed to the foundation through steel frame supports, it has a simple structure and strong load-bearing capacity, suitable for large vibrating feeders (processing capacity ≥ 1000 t/h) or high-impact load scenarios (such as feeding large chunks of ore). The bottom of the support frame is fixed with anchor bolts to ensure that the equipment does not shift under high-intensity vibration. The surface of the support frame is also treated with anti-corrosion treatment to adapt to humid and dusty working environments.

4. Vibration Damping System: A Key Link in Reducing Vibration Pollution

The vibration damping system works in conjunction with the support device to reduce the impact of equipment vibration on the surrounding environment and its own structure:

a. Bottom Vibration Damping: Vibration damping pads (such as rubber damping pads, dampers) are installed between the support device and the foundation to absorb vibration energy and reduce the amplitude of foundation vibration (usually by 30%-50%), preventing damage to the factory structure and surrounding equipment.

b. Structural Vibration Damping: The corners of the feeding trough adopt a rounded transition design to reduce vibration stress concentration; flexible joints are used at the connection between the trough and the vibration source to reduce structural wear during vibration transmission; for large equipment, a dynamic balancing device can also be equipped to avoid equipment resonance caused by high-frequency vibration. 5. Control System: The Precision Control Center

The control system enables real-time adjustment of the feeding rate and monitoring of equipment operating status. It mainly consists of a control box, sensors, and actuators:

a. Control Method: Supports manual adjustment and automatic control. Manual mode adjusts the vibration intensity via a knob; automatic mode can be connected to a PLC control system, automatically adjusting the feeding rate based on the operating load of subsequent equipment (such as crushers and screening machines) through feedback signals from pressure sensors and flow sensors, achieving closed-loop control of the production line.

b. Protection Functions: Equipped with safety devices such as overload protection, overheating protection, and phase loss protection. When the equipment experiences motor overload, abnormal vibration, or material blockage, the system automatically shuts down and sends an alarm signal to prevent equipment damage; some high-end equipment also supports remote monitoring functions, enabling data acquisition, fault diagnosis, and remote control through IoT technology.

B. Industry Application Scenarios and Practical Value of Vibrating Feeders

With their flexible adjustment performance, strong adaptability to working conditions, and stable feeding effect, vibrating feeders have been widely used in various industries such as mining, building materials production, metallurgical processing, chemical manufacturing, and environmental protection, becoming a key link connecting raw material storage and subsequent processing. Their application value is mainly reflected in improving production efficiency, ensuring equipment safety, and reducing operating costs.

1. Mining Industry: The Core Component at the Front End of Raw Material Transportation

In mining (including metal and non-metallic mines), vibrating feeders are mainly used in the raw material extraction and transportation stages of open-pit and underground mines, performing the dual functions of "uniform feeding and preliminary screening":

a. Open-pit mining: In the ore transportation line after blasting, the vibrating feeder is installed below the hopper, uniformly transporting large pieces of ore (particle size ≤ 800mm) to the jaw crusher, preventing the crusher from overloading or clogging due to uneven feeding. For example, in an open-pit iron mine with an annual output of 10 million tons, a heavy-duty vibrating feeder with a processing capacity of 1500 t/h can continuously transport the blasted ore to the crushing system, increasing the crushing efficiency by 20% and reducing the equipment failure rate by 30%. b. Underground Mining: Due to the limited space in underground tunnels, small, lightweight vibrating feeders are used to transport ore mined underground through chutes to the surface crushing plant. The feed rate can be adjusted in real time according to the lifting system's capacity, ensuring coordinated matching between underground operations and surface processing.

c. Preliminary Screening Function: In some mines, the bottom of the vibrating feeder's trough uses a screen structure, which can separate fine-grained materials (particle size ≤ 50mm) during the feeding process. These can be used directly as finished products or sent to the grinding system, reducing the processing load on the crusher and improving resource utilization efficiency.

2. Building Materials Production Industry: Equipment for Ensuring Stable Production

In the production of building materials such as cement, concrete, and sand and gravel aggregates, vibrating feeders are used in the raw material pretreatment and batching stages to ensure the continuous and stable operation of the production line:

a. Sand and Gravel Aggregate Production: In natural sand mining or artificial sand production lines, vibrating feeders uniformly transport river sand, mountain sand, or crushed stone to the screening machine. By adjusting the feed rate, the processing load of the screening machine is controlled, preventing screen overload and blockage, and improving screening efficiency. For example, in a sand and gravel aggregate production line with an annual output of 3 million tons, the vibrating feeder can control the uniformity of raw material feeding within ±5%, increasing the grading accuracy of the screening machine by 15%, and improving the qualified rate of finished sand from 85% to 98%.

c. Cement Production: In cement clinker production lines, vibrating feeders are used in the batching stage of raw materials such as limestone, clay, and iron powder. By precisely controlling the feeding ratio of each raw material (error ≤ 1%), the chemical composition of the raw materials is ensured to be uniform and stable, providing high-quality raw materials for the subsequent calcination process and improving the strength grade of cement clinker.

d. Concrete Mixing: In commercial concrete mixing plants, vibrating feeders are installed below the sand and gravel silos, transporting aggregates such as sand and stone to the mixing host according to the formula ratio. The feeding speed can be adjusted in real time according to the mixing cycle of the mixing host, preventing aggregate accumulation or insufficient supply, and ensuring the mixing quality and production efficiency of concrete. 3. Metallurgical Processing Industry: Key Equipment for Precise Batching

In the steel and non-ferrous metal smelting industries, vibratory feeders are used for conveying and batching ores, coke, and auxiliary materials, directly impacting the stability of the smelting process and product quality:

a. Steel Smelting: In blast furnace ironmaking production lines, vibratory feeders transport raw materials such as iron ore powder, coke, and limestone in proportion to the sintering machine or blast furnace. Precise control of the feeding amount (error ≤ 0.5%) ensures the uniform chemical composition of the sintered ore, improves the smelting efficiency of the blast furnace, and reduces the coke ratio (coke consumption per unit of pig iron). For example, a steel company improved the batching accuracy of sintering raw materials to ±0.3% by introducing intelligent vibratory feeders, increasing the blast furnace utilization coefficient by 8% and saving approximately 5000 tons of coke annually.

b. Non-ferrous Metal Smelting: In the smelting of non-ferrous metals such as copper and aluminum, vibratory feeders are used for conveying concentrate powder and flux. During the feeding process, the vibration of the trough can break up material clumps, preventing uneven batching caused by material clumping, ensuring sufficient smelting reaction, and improving metal recovery rate.

4. Chemical Manufacturing Industry: Safe and Efficient Material Handling Solutions

In the chemical industry, vibratory feeders are used for conveying various chemical raw materials (such as granular materials, powders, and corrosive materials). Their structural design must meet special requirements such as corrosion resistance, explosion protection, and pollution prevention:

a. Granular Material Conveying: Used in production lines for fertilizers, plastic granules, rubber granules, etc., to transport raw materials from silos to mixers, granulators, and other equipment. The uniformity of feeding prevents uneven mixing of raw materials and improves product quality stability.

b. Corrosive Material Conveying: For corrosive raw materials such as acids, alkalis, and salts, the feeding trough is made of stainless steel (304 or 316L) or fiberglass, and the vibration source adopts a sealed design to prevent material leakage and corrosion of the equipment, ensuring the service life of the equipment. c. Explosion-Proof Applications: In the transportation of flammable and explosive materials (such as coal dust and chemical powders), explosion-proof vibrating motors and electrical components are used. No sparks are generated during equipment operation, meeting explosion-proof requirements (usually Ex d IIB T4), ensuring production safety.

5. Environmental Protection Industry: Pre-treatment Guarantee for Resource Utilization

In environmental protection fields such as municipal solid waste treatment, construction waste recycling, and industrial solid waste disposal, vibrating feeders are used in the pre-treatment and sorting stages of materials, providing a foundation for resource utilization:

a. Municipal Solid Waste Treatment: In waste incineration power generation or landfill treatment production lines, vibrating feeders uniformly transport municipal solid waste from the silo to the crusher or sorting equipment. The vibration process can break up agglomerated waste clumps and separate some fine impurities (such as dust), improving the efficiency of subsequent crushing and sorting, while preventing equipment blockage.

b. Construction Waste Recycling: In construction waste sorting and recycling production lines, vibrating feeders transport crushed concrete blocks, bricks, and other materials to the screening machine. By adjusting the feeding speed and vibration intensity, the grading accuracy of recycled aggregates is ensured, improving the quality of recycled aggregates and providing a guarantee for subsequent building material recycling.

c. Industrial Solid Waste Disposal: In the resource utilization of industrial solid waste such as coal gangue and fly ash, vibrating feeders transport solid waste raw materials to grinding mills or brick-making equipment. The uniformity of feeding can improve equipment processing efficiency, reduce energy consumption, and promote the reduction and resource utilization of industrial solid waste.

C. Application Summary and Development Trends

Through scientific structural design and flexible control performance, vibrating feeders play an irreplaceable role in material conveying systems in various industries. Their core value lies in achieving "uniform feeding, precise control, and stable operation," providing high-quality raw materials for subsequent processing equipment, reducing production losses, and improving the efficiency and benefits of the overall production line. With the continuous advancement of industrial technology, vibratory feeders will develop in the following directions in the future:

1. Intelligent upgrading: Introducing AI visual recognition and adaptive control technology, using cameras to monitor material particle size, humidity, and other characteristics, automatically optimizing vibration parameters to achieve precise material feeding and intelligent sorting;

2. Large-scale and high-efficiency: Developing heavy-duty vibratory feeders with larger processing capacity (≥2000t/h) and lower energy consumption to meet the needs of large mines and building materials production lines, improving the efficiency of individual equipment;

3. Environmental protection improvements: Adopting low-noise vibration motors, sound insulation covers, and other designs to further reduce operating noise; optimizing the sealing structure to reduce dust leakage and meet environmental emission standards;

4. Adaptation to special working conditions: Developing vibratory feeders suitable for high temperatures (≥500℃), low temperatures (≤-40℃), strong corrosion, and other special working conditions to expand application fields.

For enterprises, rationally selecting the structure type and technical parameters of vibratory feeders based on their industry characteristics, material types, and production scale will lay a solid foundation for the efficient operation and sustainable development of production lines.

This article systematically explains the structural composition and core value of vibratory feeders in industrial applications. Its structure is centered on the vibration source, feeding trough, support device, damping system, and control system. Through scientific design, it achieves stable vibration and precise feeding, adapting to different materials and working conditions. In mining, building materials, metallurgy, chemical industry, environmental protection, and many other fields, this equipment, as a key pre-processing equipment for material transportation, plays an important role in uniform feeding, precise control, and ensuring the stability of the production line, improving efficiency, reducing losses and operating costs. In the future, with intelligent, large-scale, and environmentally friendly upgrades, vibratory feeders will further expand their application scenarios, providing more efficient technical support for industrial production and resource utilization.

Save Time! Get A Detailed Quotation Quickly.