In material classification scenarios across various fields such as solid waste treatment, mining, and construction materials, the shaftless trommel screen, with its unique shaftless design, overcomes the limitations of traditional shafted trommel screens and has become an ideal equipment for processing materials that are highly viscous, contain many impurities, and are prone to entanglement. Especially in the field of household waste sorting and treatment, the shaftless trommel screen, with its efficient sorting capabilities and stable operation, provides crucial technical support for the resource utilization of waste. Through a scientific structural combination and precise motion control, it achieves efficient classification of materials of different particle sizes, promoting the upgrading and optimization of material processing processes in related industries.

The shaftless trommel screen is essentially a specialized equipment that achieves particle size classification through the rotation of the drum. Its most significant feature is the elimination of the central shaft that runs through the drum in traditional trommel screens, instead relying on the structural strength of the drum itself and an external drive device for rotation. This core innovation not only simplifies the equipment structure but also fundamentally solves the problem of entanglement and blockage that traditional shafted trommel screens face when processing materials containing fibers, ropes, and large impurities. In household waste sorting and treatment, such materials (such as discarded clothing, plastic bags, branches, bricks, and stones) are very common, and the emergence of the shaftless trommel screen precisely fills the technical gap in the efficient screening of such materials, becoming a key equipment in waste sorting and treatment production lines.

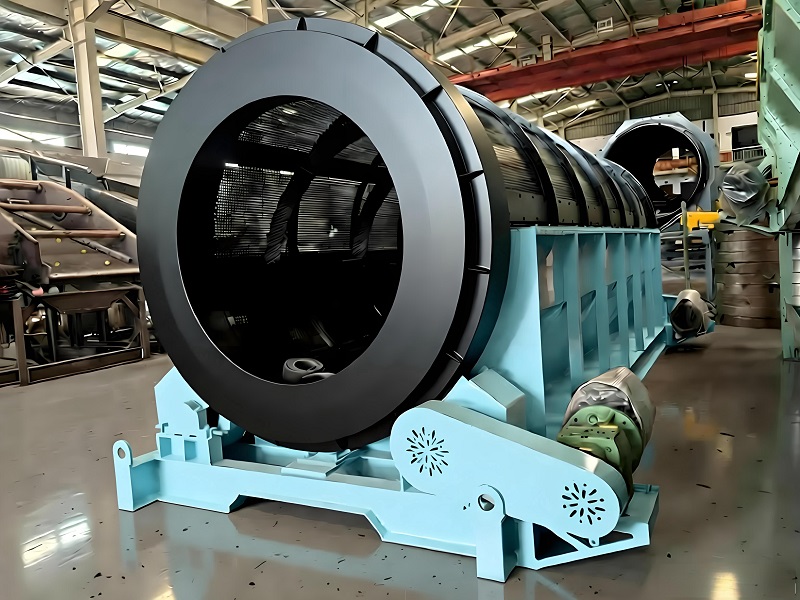

A deep understanding of the structural composition of the shaftless trommel screen is fundamental to grasping its working principle and performance advantages. The equipment's structural design revolves around the core feature of "shaftless," with each component working together to achieve stable material conveying and precise classification. Its main components include an octagonal drum, support frame, feeding device, discharge hopper, drive system (including drive motor and reducer), and auxiliary cleaning structure. Each part performs a different function during equipment operation, forming an organic whole.

The octagonal drum is the core working component of the shaftless trommel screen and one of the important features that distinguishes it from traditional circular trommel screens. Its structural design directly determines the screening efficiency and stability of the equipment. Compared to cylindrical drums, octagonal drums produce a more pronounced "tumbling effect" during rotation. As the drum rotates, the edges of the octagon periodically lift and drop the internal material, allowing for thorough dispersion and preventing incomplete screening due to material accumulation. This tumbling effect is particularly important when processing complex materials such as municipal solid waste, effectively preventing lightweight materials like plastic bags and fabrics from adhering to the screen surface and ensuring that the screen holes are not clogged.

The drum wall of the octagonal drum is assembled from screen plates. The screen plate material can be selected from stainless steel, high-manganese steel, wear-resistant alloy, etc., depending on the application. In the field of municipal solid waste sorting, stainless steel screen plates are commonly used due to their good corrosion resistance, which can withstand the acidic and alkaline substances that may be present in municipal solid waste. They are also easy to clean, preventing secondary pollution caused by material residue. The screen hole specifications can be customized according to screening requirements, ranging from a few millimeters to tens of millimeters. For example, in municipal solid waste sorting, different screen hole sizes such as 10 mm, 20 mm, and 50 mm can be used to separate materials into different grades: fine materials (such as food scraps, dust), medium materials (such as shredded paper, small plastic pieces), and coarse materials (such as bricks, large pieces of plastic). In addition, some octagonal drums feature a modular design, allowing for individual screen plate removal and replacement. When screen plates are worn or need to be adjusted for different screen hole sizes, the entire drum does not need to be replaced, effectively reducing equipment maintenance costs.

The support frame, as the "skeleton" of the shaftless trommel screen, plays a crucial role in supporting the entire weight of the equipment and ensuring its stable operation. The frame is usually welded from structural steel (such as I-beams and channel steel), providing sufficient strength and rigidity to withstand the weight of the octagonal drum and the internal materials, preventing structural deformation due to excessive vibration during operation. The bottom of the frame usually includes leveling devices and shock-absorbing pads. The leveling devices ensure that the drum is horizontal or at a preset inclination angle (generally 3°-8°, used to assist material transport), while the shock-absorbing pads absorb vibrations generated during equipment operation, reducing the impact on the ground and surrounding equipment, and also reducing the noise of the equipment itself. The feeding device and discharge hopper are key structures for achieving orderly material input and output, and their rational design directly affects the feeding stability and discharge efficiency of the equipment. The feeding device usually consists of a conveyor belt and a feeding chute. The conveying equipment (such as a belt conveyor) transports the material to be processed to the feeding chute. The feeding chute adopts an inclined design and is equipped with buffer plates inside, which can effectively slow down the material's falling speed, preventing the material from causing violent impact on the octagonal drum, and ensuring that the material is evenly distributed at the feeding end of the drum, thus ensuring the smooth start of the screening process. The discharge hopper is usually located below the drum and is divided into multiple discharge ports according to different screening grades, corresponding to undersized and oversized materials of different specifications. The inside of the hopper uses smooth lining plates to reduce material residue and blockage in the hopper, ensuring that materials of different grades can be smoothly discharged into the subsequent processing steps.

The driving system is the power source for the operation of the shaftless drum screen, mainly composed of a drive motor, a reducer, and transmission gears or support rollers. Its core function is to provide stable rotational power to the octagonal drum and control the screening efficiency by adjusting the rotation speed. Unlike traditional shafted drum screens driven by a central shaft, shaftless drum screens mainly have two driving methods: one is gear transmission, where a gear ring is set on the outside of the octagonal drum, and the drive motor drives the gear to rotate through a reducer, and the gear meshes with the gear ring, thereby driving the drum to rotate; the other is support roller transmission, where multiple support rollers are set below the drum, and the support rollers are driven to rotate by a motor and a reducer, using the friction between the support rollers and the drum to drive the drum to rotate.

These two driving methods each have their advantages. Gear transmission has high transmission efficiency and precise speed control, suitable for scenarios requiring high screening accuracy; support roller transmission has the characteristics of simple structure and convenient maintenance, which can effectively reduce the equipment failure rate, and is suitable for complex working conditions such as municipal solid waste treatment. The drive motor typically uses a variable frequency motor, allowing for flexible adjustment of the drum speed based on the material properties and screening requirements. When processing highly viscous materials, the speed can be increased to enhance material agitation and dispersion; when processing easily screened materials, the speed can be reduced to save energy.

The auxiliary cleaning structure is a crucial guarantee for the continuous and stable operation of the shaftless trommel screen, especially when processing materials that easily clog the screen holes. This structure usually includes a spraying device and a scraper cleaning device. The spraying device is located above or inside the drum, spraying clean water onto the screen surface through high-pressure nozzles. This effectively washes away fine materials and viscous substances attached to the screen holes, preventing clogging. In municipal solid waste sorting, the spraying device can also reduce dust, improving the working environment. The scraper cleaning device is located on the inner side or below the drum. The scraper is tightly fitted to the screen surface, and as the drum rotates, the scraper removes residual materials from the screen surface, further ensuring the unobstructed flow through the screen holes. Some high-end equipment is also equipped with an automatic cleaning control system, which can automatically activate the cleaning device based on the degree of screen hole clogging, enabling intelligent maintenance.

The unique structural design gives the shaftless trommel screen a series of significant features, making it stand out among many material screening devices, especially demonstrating strong advantages in complex material processing scenarios. These features are reflected not only in the equipment's operating performance but also in its adaptability to the needs of different industries, becoming an important criterion for measuring the value of the equipment.

Anti-winding and anti-clogging are the core features of the shaftless trommel screen and its key advantage over traditional shafted trommel screens. The central shaft and blades connected to the shaft of traditional shafted trommel screens are prone to entanglement with long, fibrous materials such as clothing, plastic bags, and ropes, leading to equipment failure and requiring frequent manual cleaning. This not only affects production efficiency but also increases the labor intensity of operators. The shaftless trommel screen fundamentally eliminates the carrier for material entanglement by removing the central shaft. The tumbling effect of the octagonal drum allows for thorough material dispersion, preventing the accumulation of long, fibrous materials. Combined with an auxiliary cleaning structure, this further reduces the probability of screen clogging. In municipal solid waste sorting and processing lines, this feature significantly extends the continuous operating time of the equipment, reducing downtime for maintenance by more than 60%, and significantly improving the overall processing efficiency of the production line.

High screening efficiency and precise classification are another important feature of the shaftless trommel screen. This is due to the structural design of the octagonal drum and its flexible speed adjustment function. The periodic tumbling effect generated during the rotation of the octagonal drum allows the material to fully contact the screen surface. Compared to traditional circular trommel screens, the probability of material screening is greatly increased, avoiding the "underscreening" problem caused by material accumulation. At the same time, the variable frequency motor drive system can precisely adjust the drum speed according to the particle size distribution and screening requirements, achieving fine-tuned control of the screening process. For example, when processing municipal solid waste containing a large amount of fine material, the speed can be appropriately reduced to allow sufficient time for the fine material to pass through the screen holes; when processing materials mainly composed of coarse materials, the speed can be increased to accelerate the material conveying and classification speed. Actual applications have verified that the screening efficiency of the shaftless trommel screen can reach over 90%, far exceeding that of traditional shafted trommel screens, and the classification accuracy error can be controlled within 5%, meeting the strict requirements for material classification in various industries.

Strong adaptability and a wide range of materials processed are among the significant advantages of the shaftless trommel screen. This equipment can not only handle complex materials such as municipal solid waste and kitchen waste, but also be used in various fields such as ore screening in the mining industry, sand and gravel classification in the construction industry, and granular material screening in the chemical industry. It has strong adaptability to the humidity, viscosity, and particle size characteristics of materials. Whether it is wet waste with a water content as high as 30% or highly viscous slag, stable screening can be achieved. When processing large materials, the advantages of the shaftless trommel screen are even more pronounced. Due to the absence of a central shaft, the effective space inside the drum is larger, accommodating larger diameter materials (such as bricks and stones up to 500 mm in diameter), avoiding the problem of large materials getting stuck due to the obstruction of the central shaft in traditional equipment. This wide adaptability allows the shaftless trommel screen to flexibly meet the needs of different industries, reducing equipment investment costs for businesses.

Simple structure and easy maintenance are prominent features of the shaftless trommel screen in terms of operating costs. Compared to the complex central shaft transmission structure of traditional shafted trommel screens, the shaftless trommel screen has fewer parts and a simpler structure, reducing potential failure points. For example, the shaftless trommel screen with roller drive only uses friction between the rollers and the drum for driving, eliminating the need for complex gearboxes and couplings, significantly reducing equipment failure rates. In terms of maintenance, the modular screen plate design makes screen plate replacement more convenient; operators can complete the removal and installation of screen plates without professional tools. Maintenance of the drive system and auxiliary cleaning structure is also relatively simple; regular lubrication and cleaning ensure stable operation of the equipment. Statistics show that the annual maintenance cost of a shaftless trommel screen is only 50%-70% of that of a traditional shafted trommel screen, saving businesses significant maintenance costs.

Stable operation and low energy consumption are important aspects of the shaftless trommel screen's performance. The rigid design of the support frame and the application of shock absorbers result in low vibration and noise during operation, leading to more stable operation and extending the equipment's service life. In terms of energy consumption, the shaftless design reduces energy loss during the transmission process, and the application of variable frequency motors enables on-demand power supply, avoiding energy waste. Compared with traditional shafted trommel screens with the same processing capacity, the energy consumption of the shaftless trommel screen can be reduced by 15%-25%, especially in large-scale production lines, where long-term operation can save businesses considerable energy costs. In scenarios such as 24-hour continuous operation in household waste sorting and processing, the economic benefits brought by low energy consumption are even more significant.

Good environmental performance is an important characteristic of the shaftless trommel screen, meeting the needs of modern industrial development. In household waste sorting and processing, the environmental performance of the equipment directly relates to the working environment and the surrounding ecological environment. The shaftless trommel screen is equipped with a spray dust suppression system, which effectively suppresses dust generated during the screening process, controlling the dust concentration in the working environment within the national standard (≤10mg/m³), thus protecting the health of operators. At the same time, the equipment uses corrosion-resistant materials such as stainless steel, preventing secondary pollution caused by contact between materials and the equipment, ensuring that the screened materials meet the requirements for subsequent resource utilization. Furthermore, the equipment operates with low noise (typically ≤75 decibels), avoiding disruption to the lives of surrounding residents and aligning with the development trend of environmentally friendly industrial equipment.

In practical applications, these features of the shaftless trommel screen combine to form a powerful comprehensive advantage. Taking a municipal solid waste treatment plant as an example, after introducing the shaftless trommel screen, the daily processing capacity of municipal solid waste increased from 800 tons to 1200 tons, the screening efficiency increased from 75% to 92%, the equipment downtime for maintenance decreased from 4 hours per day to 1 hour, and the annual maintenance cost was reduced by 400,000 RMB. Simultaneously, the classification of screened materials became more precise, the recycling rate of recyclable materials increased by 15%, and the amount of landfill waste decreased by 20%, effectively promoting the resource utilization and reduction of municipal solid waste, achieving significant economic and environmental benefits.

With the continuous improvement of environmental protection requirements and the ongoing development of the material processing industry, the application prospects of shaftless trommel screens will become even broader. In the future, by combining intelligent technologies, such as using IoT sensors to monitor equipment operating status in real time and utilizing artificial intelligence algorithms to optimize screening parameters, shaftless trommel screens will achieve more efficient and intelligent operation, further enhancing their application value in various industries. For enterprises, choosing the appropriate shaftless trommel screen equipment requires considering their own material characteristics, processing capacity requirements, and application scenarios, consulting professional equipment manufacturers to obtain customized solutions, and fully leveraging the advantages of the equipment to improve production efficiency and economic benefits.

Save Time! Get A Detailed Quotation Quickly.