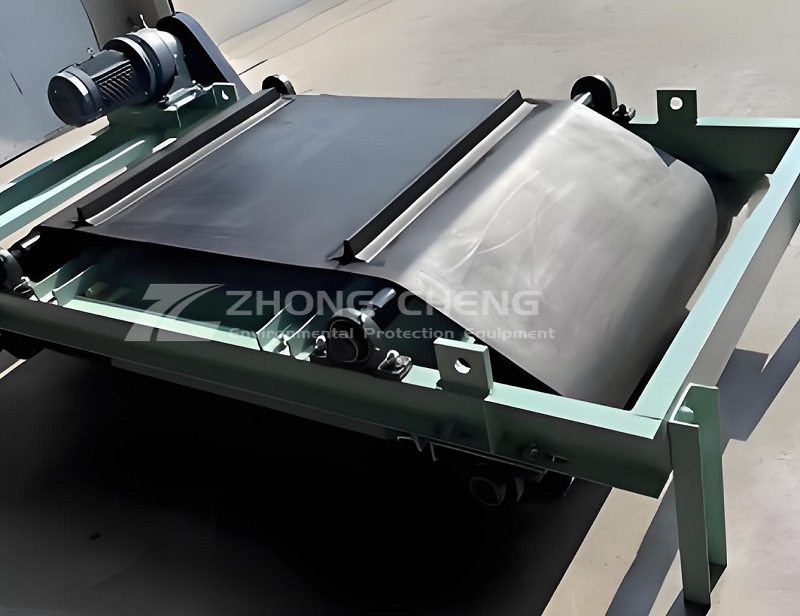

As a core component of metal separation in waste screening systems, the installation accuracy and maintenance quality of plate-mounted magnetic separators directly determine metal recovery rates, equipment lifespan, and overall process stability. In complex operating conditions such as waste treatment involving high dust and strong corrosion, improper installation can easily lead to equipment vibration and conveyor belt misalignment, while neglecting daily maintenance can cause magnetic field attenuation, component wear, and other malfunctions, affecting processing efficiency. This article, based on the actual application scenarios of environmental waste treatment, systematically outlines the installation specifications, commissioning procedures, and key points of daily maintenance for plate-mounted magnetic separators, providing professional and practical guidance to help companies avoid equipment hazards and ensure continuous and efficient operation of the screening process.

I. Installation Specifications for Flat Plate Magnetic Separators (Including Preliminary Preparation and On-site Implementation)

As a key piece of equipment for metal separation in waste screening, the installation quality of flat plate magnetic separators directly affects the metal recovery rate and equipment lifespan. It is necessary to follow the core principles of "precise positioning, standardized assembly, and safe commissioning," and implement the installation in three orderly stages:

1. Pre-installation Preparation

Site and Foundation Preparation: Based on the equipment model (e.g., standard models with a bandwidth of 800-1600mm), reserve sufficient installation space. The width of the passageway around the equipment should be no less than 1.2m to facilitate subsequent maintenance. The installation foundation must be poured with C30 concrete, with a ground flatness error controlled within 3mm/m. The foundation bearing capacity must meet at least 1.5 times the equipment's self-weight (for standard models, the foundation dimensions (length × width × height) should be no less than 1.5m × 1.0m × 0.8m) to avoid vibration and displacement during operation. Simultaneously, clean up debris and dust in the installation area to ensure no obstructions affect installation operations.

Equipment and Accessory Inspection: After unpacking, check the completeness of each accessory, including the main unit, magnetic plate assembly, conveyor belt, drive motor, reducer, and fasteners. Verify model compatibility against the equipment manual. Pay special attention to checking the magnetic plate surface for scratches or damage, and verifying that the magnetic field strength meets the specified value (the magnetic field strength of a plate magnetic separator for waste treatment is typically 8000-12000 Gs). Inspect the conveyor belt for cracks and joint tightness, and check the motor and reducer for oil leaks, abnormal noises, or other factory defects. Contact the supplier immediately if any problems are found.

Tools and Personnel: Prepare lifting equipment (e.g., a 5-10 ton crane), a level, torque wrench, measuring tape, welding machine, etc., and assign 2-3 professional installation personnel (familiar with mechanical assembly procedures and electrical wiring specifications). Study the equipment installation manual in advance to understand the installation sequence and technical requirements of each component to avoid improper operation.

2. On-site Installation Procedure

Main Unit Positioning and Fixing: Use a crane to smoothly lift the main unit onto the installation foundation. Adjust the equipment's level using a level, ensuring that the horizontal and vertical level errors do not exceed 0.5mm/m. After positioning, use expansion bolts (M20-M24 specifications) to firmly connect the equipment base to the concrete foundation. Control the bolt tightening torque to 350-400 N·m, ensuring a tight fit between the base and the foundation without gaps to prevent resonance during operation.

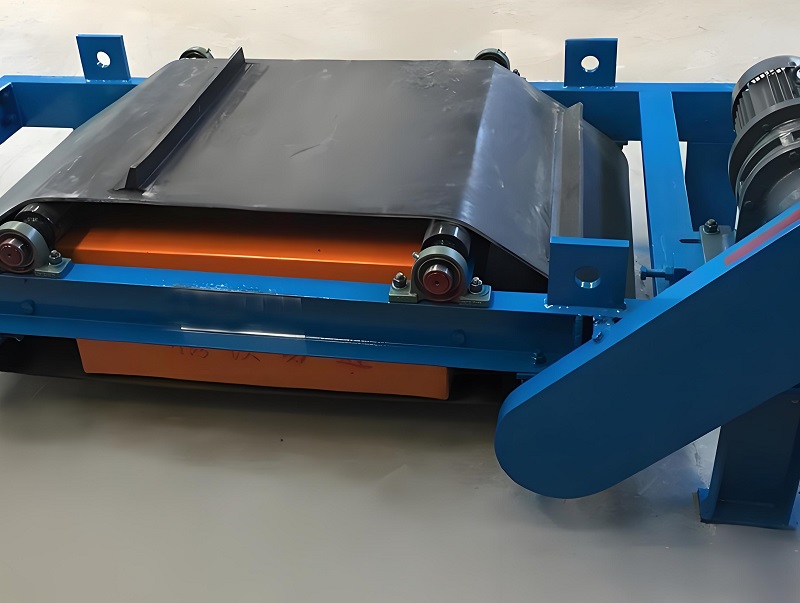

Magnetic Plate Assembly Installation: Embed the magnetic plate assembly (usually detachable) into the main unit frame according to the instructions. The gap between the magnetic plates should not exceed 2mm, and the surface flatness error should be ≤1mm/m. During installation, pay attention to the polarity arrangement of the magnetic plates (adjacent magnetic plates have opposite polarities to enhance the adsorption effect) and fix them with stainless steel bolts to prevent the magnetic plates from loosening and falling off during operation. After installation, use a magnetic field tester to check the magnetic field distribution on the surface of the magnetic plates to ensure there are no obvious weak areas in the magnetic field.

Conveyor Belt Assembly and Adjustment: Place the conveyor belt onto the drive and driven rollers, adjusting their parallelism to ensure the conveyor belt centerline deviates from the equipment centerline by no more than 5mm. Adjust the tensioning device (screw or hydraulic tensioner) to achieve appropriate belt tension; a 10-15mm deflection at the center of the conveyor belt when manually pressed is ideal. Start the conveyor belt under no-load and observe for any deviation. If deviation occurs, adjust the adjusting bolts on the driven roller to correct it, ensuring smooth, friction-free conveyor belt operation.

Electrical System Wiring: Connect the motor, control system, and power supply according to the equipment's electrical schematic. Wiring must be secure and reliable, with wires neatly arranged, and the grounding resistance not exceeding 4Ω. Verify the voltage rating of the motor wiring (usually 380V three-phase AC) and ensure correct forward and reverse directions (the conveyor belt's running direction should be consistent with the waste conveying direction, and the magnetic plate's adsorption surface should face the material). After wiring, check the insulation performance; use a megohmmeter to measure the insulation resistance, ensuring it is not less than 1MΩ to prevent short circuits.

3. Post-Installation Commissioning Procedure

No-Load Commissioning: After connecting the power supply, start the equipment and run it under no-load for 30-60 minutes. Observe the motor operating current (should be 60%-80% of the rated current), reducer oil temperature (not exceeding 60℃), and check whether the conveyor belt speed (0.8-1.2m/s for conventional models) is stable, and whether the magnetic plate assembly is loose or makes abnormal noises. Use an infrared thermometer to check the bearing temperature (not exceeding 70℃) to ensure that all moving parts are operating normally.

Load Commissioning: Feed the mixed material (containing metal impurities) after waste screening to the magnetic separator at a uniform speed. Adjust the feed rate (matching the conveyor belt speed, usually 50-100t/h) and observe the metal adsorption effect. Check whether metal impurities (such as iron nails, rebar ends, aluminum cans, etc.) can be effectively adsorbed by the magnetic plate, and whether the adsorbed metal can be smoothly detached from the end of the conveyor belt (this can be assisted by adjusting the position of the discharge plate). Record the metal recovery rate (which should be no less than 95%). If the recovery rate is below the standard, check the magnetic field strength, conveyor belt speed, or feed uniformity, and make targeted adjustments.

Safety and Environmental Inspection: During commissioning, check the effectiveness of safety devices such as equipment guardrails and emergency stop buttons to ensure no material splashing or dust leakage during equipment operation. Inspect the equipment's sealed parts to prevent dust from entering the motor, bearings, and other components. Simultaneously, confirm that the equipment's operating noise does not exceed 85dB, meeting environmental standards. After successful commissioning, complete the installation and commissioning report and archive it for future reference.

II. Daily Maintenance Points for Flat Plate Magnetic Separators (including cleaning, inspection, and troubleshooting) Flat plate magnetic separators face challenges such as high dust levels, highly corrosive materials, and heavy operating loads in waste screening environments. A maintenance system of "daily cleaning, regular inspection, and timely repair" is necessary to ensure long-term stable operation of the equipment.

1. Daily Cleaning (After Daily Operation)

Surface and Magnetic Plate Cleaning: Use a high-pressure water gun (water pressure controlled at 0.3-0.5MPa) to rinse the equipment surface, conveyor belt, and magnetic plate adsorption surface to remove residual garbage, dust, and corrosive substances (such as leachate from kitchen waste). Avoid using hard tools to scrape the magnetic plates when cleaning, as this may damage the surface coating and affect the magnetic field strength. For stubborn stains, use a neutral detergent to wipe, then rinse thoroughly with clean water.

Conveyor Belt Cleaning: Clean any adhering materials from the conveyor belt surface and check for material residue at the conveyor belt joints to prevent long-term accumulation that could loosen the joints. If there is oil on the conveyor belt surface, clean it with a special degreaser to ensure normal conveyor belt friction and prevent material slippage.

Equipment Surrounding Area Cleaning: Clean up garbage and dust around the equipment, keeping the installation area well-ventilated and dry to prevent dust accumulation in the motor, reducer, and other components, and to prevent leachate buildup that could corrode the equipment base.

2. Regular Inspections (Daily, Weekly, and Monthly Frequency)

Daily Inspection Items: Before starting the machine, check the conveyor belt tension and surface for damage; during operation, observe the motor's operating sound and current to ensure they are normal, and check for oil leaks in the reducer; after stopping the machine, check for any metal debris residue on the magnetic plate's adsorption surface and ensure the safety protection devices are intact. If problems such as conveyor belt misalignment or decreased magnetic plate adsorption force are found, address them promptly before restarting the machine.

Weekly Inspection Items: Remove the equipment protective cover, check the lubrication of the drive and driven roller bearings, and replenish lithium-based grease (filling to 1/2-2/3 of the bearing cavity); check if the magnetic plate fixing bolts are loose, and retighten them with a torque wrench (torque value consistent with installation); measure the operating temperature of the motor and reducer to ensure it does not exceed the rated limits; check for loose or oxidized electrical wiring terminals, and tighten or replace them as needed.

Monthly Inspection Items: Conduct a comprehensive inspection of the magnetic field strength of the magnetic plate. If the magnetic field strength decreases by more than 10%, contact the manufacturer for remagnetization. Inspect the conveyor belt for wear. If the thickness decreases by more than 30% or cracks appear, replace it immediately. Disassemble and inspect the wear of the gears and the quality of the lubricating oil inside the reducer. If the lubricating oil is deteriorated (blackened, contains impurities), replace it immediately (use the industrial gear oil specified in the instruction manual). Check the motor insulation performance to ensure there is no risk of leakage.

3. Common Fault Handling and Maintenance Taboos

Common Faults and Solutions

Low Metal Recovery Rate: Possible causes include decreased magnetic field strength, excessive conveyor belt speed, and uneven feeding. Solutions: Inspect the magnetic field strength of the magnetic plate and remagnetize if necessary; adjust the conveyor belt speed to 0.8-1.2 m/s; optimize the feeding device to ensure even material distribution on the conveyor belt.

Conveyor Belt Misalignment: Causes include roller parallelism deviation and uneven conveyor belt tension. Solutions: Adjust the driven roller adjusting bolts to correct roller parallelism; adjust the tensioning device to ensure consistent tension on both sides of the conveyor belt.

Motor overheating: Causes include excessive load, poor bearing lubrication, and loose electrical wiring. Solutions: Reduce feed rate to avoid overloading; replenish or replace bearing grease; check electrical wiring and tighten loose terminals.

Gearbox oil leakage: Causes include aging seals and excessive lubricating oil. Solutions: Replace aging seals and oil seals; drain excess lubricating oil to the level specified in the instruction manual.

Maintenance Precautions: Do not perform cleaning or maintenance while the equipment is running. The machine must be stopped and the power disconnected. Display a "Do Not Operate" sign.

Do not strike the magnetic plate with iron objects or strong magnetic fields to avoid demagnetizing or damaging the magnetic plate.

Do not arbitrarily adjust the polarity of the magnetic plate or disassemble the magnetic plate assembly. For maintenance, contact a qualified technician.

Do not use substandard lubricating oil, fasteners, or other accessories, as this may affect equipment performance and lifespan.

4. Long-Term Shutdown Maintenance

If the equipment needs to be shut down for more than 15 days, the following maintenance is required: Clean debris and dust from inside and outside the equipment; loosen the conveyor belt; apply anti-rust oil to moving parts such as bearings and gears; cover the equipment with a waterproof cover to prevent moisture and dust; periodically (every 7 days) start the equipment and run it unloaded for 10 minutes to ensure smooth operation of components. Before restarting, conduct a comprehensive inspection of the equipment status and only put it into use after confirming that everything is in order.

The installation of the flat-plate magnetic separator should follow the three-stage principle of "preliminary preparation - standardized assembly - precise debugging." From site foundation and equipment inspection to positioning and fixing and electrical wiring, key parameters must be controlled to ensure that the installation quality meets standards. Daily maintenance focuses on "cleaning as the foundation, regular inspection as the priority, and rapid troubleshooting as a supplement." Through daily cleaning, frequencyd inspections, and targeted troubleshooting, the challenges of dust and corrosion can be addressed. This complete installation and maintenance system ensures stable equipment operation, maintains a high metal recovery rate, and reduces operating costs. Strict adherence to relevant standards can effectively extend the equipment's lifespan and ensure its continued core role in metal separation during waste screening, meeting the high-efficiency requirements of environmental protection treatment.

Save Time! Get A Detailed Quotation Quickly.