In the field of industrial material sorting, efficient screening equipment is crucial for ensuring smooth production processes. Rotary drum screens, with their unique rotary screening structure, can precisely separate materials according to particle size, especially when handling sticky, wet, or large materials, where their advantages far surpass those of vibrating screens and linear screens. They are not only the core link between raw material pretreatment and finished product grading, but also widely used in mining, construction, environmental protection, agriculture, and many other industries. The following will delve into the practical value of rotary drum screens from two aspects: diverse application scenarios and core features, providing a reference for selection in relevant industries.

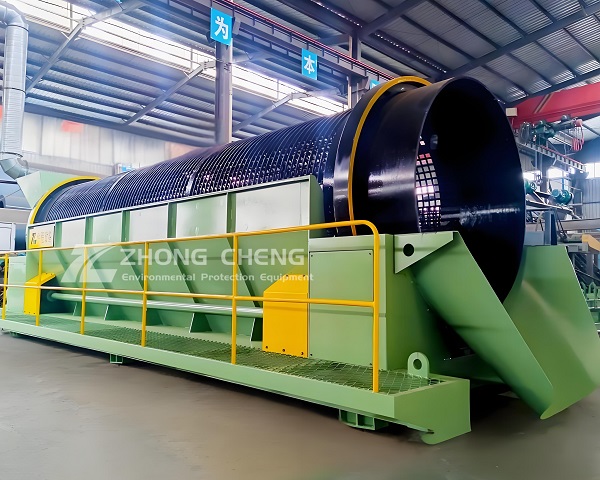

In the field of industrial material sorting, rotary drum screens, with their unique rotary screening structure and stable processing capacity, have become a key piece of equipment linking raw material pretreatment and finished product grading. Driven by a motor, the drum rotates at a uniform speed, utilizing screens with different aperture sizes inside the drum to separate mixed materials according to particle size differences, achieving the core goal of "sorting on demand." Compared to vibrating screens and linear screens, rotary drum screens have a more prominent advantage when handling sticky, wet, or large materials, and are widely used in mining, construction, environmental protection, agriculture, and many other industries. The following section will comprehensively analyze the practical value and technological advantages of rotary drum screens from two aspects: application scenarios and core features.

Diverse Application Scenarios of Rotary Drum Screens: Covering the Sorting Needs of Multiple Industries

The application scenarios of rotary drum screens revolve around three core needs: material grading, impurity removal, and pretreatment. Different industries customize the structure, screen type, and processing capacity of rotary drum screens according to material characteristics and production goals, forming diverse application models.

1. Mining Industry: "Front-End Guarantee" for Ore Pretreatment and Grading

The mining industry is one of the core application areas of rotary drum screens. They are mainly used for coarse screening and grading after ore mining, reducing the load on subsequent crushing and beneficiation processes and improving overall production efficiency. In metal ore mining (such as iron ore and copper ore), the raw ore often contains large rocks, soil, and other impurities. If these are directly fed into the crusher, it can easily lead to equipment blockage and accelerated wear. At this stage, the rotary drum screen (mostly a "heavy-duty rotary drum screen") pre-processes the raw ore: the drum diameter is typically 1.2-2.5 meters, and the length is 3-6 meters. The screen mesh is made of manganese steel woven mesh (aperture 50-200mm). Through low-speed rotation at 15-25 rpm, ore smaller than the screen aperture (meeting crushing requirements) is conveyed to the crusher, while large rocks and impurities larger than the screen aperture are discharged from the end of the drum for separate secondary crushing or disposal. Data from an iron ore project shows that after equipping the machine with a heavy-duty rotary drum screen, the crusher's jamming failure rate decreased by 55%, equipment lifespan was extended by 30%, and annual maintenance costs were reduced by 400,000 yuan.

In non-metallic mineral processing (such as limestone and quartz sand), rotary drum screens are used for "finished product grading," achieving precise sorting of products of different specifications. Taking quartz sand production as an example, after crushing and grinding, the mixed sand particles need to be graded into fine sand (0.5-1mm), medium sand (1-2mm), and coarse sand (2-5mm) by a drum screen (screen aperture 0.5-5mm). Fine sand is used in glass manufacturing, medium sand in building mortar, and coarse sand in concrete aggregate, achieving "multi-purpose use of one material." These drum screens often employ a "multi-layer screen design" (2-3 layers), enabling multi-level grading in one pass, with a processing capacity of 50-200 tons/hour, more than twice the efficiency of traditional single-layer screening equipment.

2. Construction Industry: A "Key Tool" for Construction Waste Resource Utilization and Sand and Gravel Processing

With the advancement of the "construction waste resource utilization" policy, drum screens have become core equipment in construction waste processing lines, mainly used to separate recyclable materials and impurities from construction waste, achieving resource recycling. Construction waste (such as discarded concrete blocks, bricks, and reinforcing bars) is coarsely crushed by a jaw crusher and then sorted by a drum screen. The drum screen is equipped with two layers of screens: the upper screen (30-50mm aperture) separates large concrete blocks (which are returned to the crusher for secondary crushing), while the lower screen (5-30mm aperture) separates recycled aggregate (used for making concrete blocks and road base layers). Stone powder smaller than 5mm is used as raw material for dry mortar. Simultaneously, a magnetic separator is installed next to the drum screen to separate magnetic metals such as reinforcing bars and wires from the aggregate, further improving the purity of the recycled aggregate. In a construction waste treatment project, the application of drum screens increased the resource recovery rate of construction waste from 60% to 85%, producing 150,000 tons of recycled aggregate annually, reducing landfill land by approximately 120 acres, and generating economic benefits exceeding 2 million yuan.

In construction aggregate processing, drum screens are used for "sand and gravel impurity removal," removing mud and impurities from natural sand and gravel to improve their quality. Natural sand and gravel raw materials often contain 20%-30% soil and silt. If used directly in concrete production, this will reduce the concrete's strength. In this case, a drum screen (mostly a "shaftless drum screen" to avoid soil entanglement on the shaft) is used in conjunction with a washing device: after the sand and gravel enter the drum, they come into contact with high-pressure water during rotation. The soil and silt are discharged with the water flow, while the clean sand and gravel are graded through the screen to obtain qualified products. The advantages of a shaftless drum screen are its simple structure, resistance to clogging, processing capacity of 80-150 tons/hour, and a soil removal rate of over 90%, meeting the mud content standard (≤3%) for construction sand.

3. Environmental Protection Industry: An "Environmental Assistant" for Municipal Solid Waste Treatment and Sorting

In the environmental protection field, drum screens are mainly used for municipal solid waste sorting and industrial solid waste treatment, achieving the treatment goals of "reduction, harmlessness, and resource recovery." In municipal solid waste treatment, rotary drum screens (mostly "sealed rotary drum screens" to prevent odor diffusion) are used for "waste component separation": After manual sorting to remove large debris (such as furniture and plastic buckets), municipal solid waste enters the rotary drum screen. The screen mesh size is set at 20-80mm depending on the characteristics of the waste. Through rotation, the waste is separated into "oversize" (large organic matter, such as vegetable leaves and fruit peels, used for composting or incineration) and "undersize" (fine inorganic matter, such as pebbles and glass, used for landfill). Simultaneously, some rotary drum screens are equipped with air separation devices to separate lightweight plastics from the oversize, further improving resource recovery efficiency. Data from a municipal solid waste treatment plant shows that the application of sealed rotary drum screens increases waste incineration efficiency by 15% (large organic matter is easier to burn), increases the purity of compost raw materials by 25%, and reduces landfill volume by approximately 30,000 tons annually.

In industrial solid waste treatment, rotary drum screens are used for "solid waste grading and purification." For example, waste residues generated in the chemical industry (such as gypsum slag and fly ash) may contain recyclable useful components (such as unreacted raw materials and metal particles). A drum screen, using meshes of different sizes, can separate coarse particles (for reuse in the production system) and fine powders (for harmless treatment). In the electroplating industry, drum screens can separate metal scraps (such as copper and iron filings) from electroplating waste residues, enabling metal resource recovery and reducing heavy metal pollution when used in conjunction with magnetic separation equipment. One chemical company, after implementing drum screens, increased its industrial waste residue recovery rate from 30% to 55%, reducing solid waste emissions by 1200 tons annually, while generating 500,000 yuan in revenue from recovered metal raw materials.

4. Agriculture: A "Sorting Tool" for Grain Cleaning and Organic Fertilizer Production

In agricultural production, drum screens are used for grain cleaning and organic fertilizer processing, improving the quality of agricultural products and fertilizer utilization. In grain processing (such as wheat, corn, and rice), rotary drum screens (mostly lightweight rotary drum screens with nylon woven mesh) are used for grain impurity removal. Harvested grains often contain impurities such as weeds, straw, stones, and soil. As the rotary drum screen rotates (with a mesh size of 2-5mm), the grain particles pass through the mesh and enter subsequent processing (such as hulling and grinding), while the impurities remain on the screen surface and are discharged. These rotary drum screens are small in size, have low energy consumption (1.5-3kW), and can process 5-20 tons per hour, achieving an impurity removal rate of over 95%. This ensures that the grain is not prone to mold during storage and improves the purity of the finished grain (e.g., reducing the ash content of flour by 0.2%).

In organic fertilizer production, rotary drum screens are used for organic fertilizer grading, enabling precise matching of fertilizers with different particle sizes. After fermentation and composting, organic fertilizer raw materials (such as livestock and poultry manure, straw, and dead branches) need to be graded using a drum screen (screen mesh size 1-10mm): fine powder organic fertilizer smaller than 3mm is used for vegetable and flower cultivation (easily absorbed); granular organic fertilizer of 3-10mm is used for fruit tree and crop cultivation (good slow-release effect); while uncomposted raw materials larger than 10mm are returned to the fermentation system for secondary processing. The application of drum screens has increased the organic fertilizer product qualification rate from 70% to 98%, improved fertilizer utilization by 30%, and led to a 40% increase in annual sales for one organic fertilizer company, resulting in significant economic benefits.

Core Features of Drum Screens: Technical Advantages Adaptable to Multiple Scenarios

The reason why drum screens are widely used in multiple industries lies in their unique structural design and performance advantages. They can solve the pain points of traditional screening equipment (such as vibrating screens) when processing specific materials, meeting the personalized needs of different scenarios.

1. Reasonable Structural Design: Less Prone to Clogging, Suitable for Sticky and Moist Materials

Traditional vibrating screens are prone to screen clogging when processing sticky and moist materials (such as clay, sludge, and wet sand), requiring frequent shutdowns for cleaning and impacting production efficiency. Rotary drum screens, however, utilize a "rotary screening" principle. The material inside the drum rotates with the screen, undergoing "tumbling and rolling" motions, preventing it from sticking tightly to the screen. Furthermore, some rotary drum screens are equipped with "screen cleaning devices" (such as brushes or ball bearings) that automatically clean the screen openings during drum rotation, effectively preventing clogging. For example, when processing wet sand with a moisture content of over 30%, a vibrating screen requires cleaning every hour, while a rotary drum screen (equipped with a ball bearing cleaning device) can operate continuously for over 8 hours, reducing the cleaning frequency by 87.5% and increasing processing efficiency by 3 times.

In addition, the "shaftless design" of the rotary drum screen (in some models) further reduces the risk of clogging. Shaftless drum screens eliminate the central shaft of traditional drum screens, using rollers to support the drum's rotation. This avoids the problem of fibers, straw, and other materials getting entangled in the shaft, making them particularly suitable for scenarios containing large amounts of fibrous impurities, such as construction waste and municipal solid waste. Comparative data from a municipal solid waste treatment plant shows that the clogging failure rate of shaftless drum screens is only 5%, while the clogging failure rate of traditional shafted drum screens reaches 35%, reducing maintenance time by 80%.

2. Stable Screening Efficiency: High Processing Capacity, Adaptable to Materials of Different Particle Sizes

The screening efficiency of drum screens is less affected by material characteristics, with a large and stable processing capacity, adaptable to a wide range of particle sizes (0.5mm-500mm), from fine powder to large pieces. On the one hand, the drum screen has a large screening area (the product of the drum's circumference and length). For example, a drum screen with a diameter of 2 meters and a length of 5 meters has a screening area of 31.4 square meters, which is 2-3 times that of a vibrating screen of the same specifications. It can process a large amount of material simultaneously, with a throughput of 50-300 tons/hour, meeting the continuous production needs of large production lines. On the other hand, the drum screen has a controllable rotation speed (usually 10-30 rpm), which can be adjusted according to the particle size and specific gravity of the material: a low speed (10-15 rpm) is used when processing large pieces of material to ensure thorough screening; a high speed (20-30 rpm) is used when processing fine powder materials to improve screening efficiency. In a certain mining project, the drum screen's throughput remained stable at 200 tons/hour, with a screening efficiency (pass rate of qualified material) of 92%, which is 7 percentage points higher than that of a vibrating screen (85%). Meanwhile, the "multi-layer screen design" of the drum screen enables multi-stage grading in a single operation, further improving efficiency. For example, a three-layer drum screen can simultaneously separate four different particle sizes without multiple screenings, reducing 2-3 processes compared to traditional single-layer equipment, shortening the production cycle by 50%, and lowering labor costs by 60%.

3. Stable and Reliable Operation: Low Wear and Low Maintenance Costs. The drum screen has fewer moving parts and more uniform force distribution, resulting in less wear, a longer service life, and significantly lower maintenance costs compared to traditional screening equipment. Structurally, the core moving parts of the drum screen are the drum and the idler rollers. The drum is welded from thick-walled steel plates (8-15mm thick) and coated with a wear-resistant coating (such as tungsten carbide), increasing wear resistance by 5 times and extending its service life to 5-8 years. The idler rollers feature sealed bearings, providing excellent dust and water resistance, a low failure rate, and a replacement cycle of 2-3 years. Data from a construction aggregate plant shows that the annual maintenance cost of a drum screen is only 15,000 yuan, while the annual maintenance cost of a vibrating screen with the same processing capacity reaches 60,000 yuan, representing a 75% reduction in maintenance costs.

Furthermore, the drum screen's "low-speed operation" (10-30 rpm) reduces equipment vibration and noise. Operating noise is typically below 75 decibels, far lower than that of a vibrating screen (90-100 decibels), meeting industrial noise emission standards (≤85 decibels), improving the working environment for operators, and reducing noise pollution. Simultaneously, low-speed operation also reduces equipment vibration and impact, requiring less stringent foundation requirements and eliminating the need for complex vibration damping devices, thus reducing installation costs by 40%.

4. High Adaptability: Customizable to Meet Individual Needs The structure, material, and screen type of the drum screen can be customized according to different industries and material characteristics, offering extremely high adaptability. Regarding material selection, for common materials (such as sand and gravel, ore), the drum is made of carbon steel (low cost, high strength); for corrosive materials (such as chemical waste residue, salt slag from seawater desalination), the drum is made of 304/316 stainless steel (corrosion resistant, easy to clean); for high-temperature materials (such as roasted ore from mines, metallurgical waste residue), the drum is made of high-temperature resistant alloy material (capable of withstanding temperatures above 500℃).

Regarding screen type, different screens are selected based on the particle size and characteristics of the material: for coarse-grained materials (such as ore, construction waste), manganese steel woven mesh or perforated steel plate mesh (high strength, good wear resistance) are used; for fine powder materials (such as flour, organic fertilizer), nylon woven mesh or stainless steel woven mesh (high screening accuracy, not easy to rust) are used; for sticky materials (such as clay, sludge), strip screens are used (large gaps, not easy to clog).

In terms of functional expansion, rotary drum screens can be combined with other equipment (such as magnetic separators, washing devices, and air separators) to form an integrated production line for "screening - impurity removal - purification." For example, in construction waste treatment, a rotary drum screen combined with a magnetic separator achieves simultaneous separation of aggregates and metals; in sand and gravel processing, a rotary drum screen combined with a washing device achieves simultaneous impurity removal and washing of sand and gravel, meeting the personalized production needs of different scenarios.

Droll drum screens cover the sorting needs of multiple industries with diverse application scenarios, playing an important role from ore pretreatment in mines to organic fertilizer grading in agriculture. Their characteristics of being less prone to clogging, having stable efficiency, low maintenance costs, and strong adaptability solve many pain points of traditional screening equipment. As industries demand higher sorting accuracy and efficiency, rotary drum screens will continue to optimize their customization and intelligence levels, providing strong support for cost reduction and efficiency improvement in various industries and promoting resource recycling.

Save Time! Get A Detailed Quotation Quickly.