In industrial material pretreatment processes, the efficiency and stability of the coarse screening stage directly affect subsequent processes. Bar screens, with their screen surface composed of parallel metal bars and flexible gap design, have become core equipment for processing large, high-hardness materials. They can accurately achieve "retaining large impurities and releasing qualified materials," and are widely used in mining, construction, metallurgy, and other industries. Compared to ordinary screening equipment, they have significant advantages in wear resistance and anti-clogging, serving as the "front-line defense" to ensure continuous operation of the production line. The following will analyze its core function and typical characteristics in detail, providing a reference for industry selection.

In industrial material pretreatment systems, bar screens, as key equipment for coarse and pre-screening, with their screen surface structure composed of parallel metal bars, become the "first line of defense" for processing large, high-hardness materials containing impurities. Through motor-driven screen body vibration or the oscillation of the bars themselves, and utilizing the fixed gaps between the bars, they achieve the separation goal of "retaining large materials and allowing small materials to pass through," and are widely used in industries such as mining, construction, and metallurgy where high coarse screening efficiency is required. Compared to ordinary screening equipment, bar screens offer significant advantages in wear resistance, clogging prevention, and adaptability to high-hardness materials, making them crucial pre-processing equipment for ensuring efficient operation of subsequent crushing and sorting processes. The following section will comprehensively analyze the practical value and technical advantages of bar screens from two aspects: their core functions and typical characteristics.

The Core Function of Bar Screens:

Focusing on Coarse Screening and Pre-treatment, Strengthening the Front-End of Production The function of bar screens revolves around three core objectives: "coarse particle separation, impurity interception, and protection of subsequent equipment." In different industry scenarios, by adapting to different bar gaps and structural designs, they meet diverse pre-treatment needs, clearing obstacles for subsequent production processes.

1. Mining Industry: Coarse Screening and Grading of Ore, Reducing the Load on Crushing Equipment The mining industry is the core application area for bar screens, primarily used for "coarse screening pre-treatment" after ore mining. This separates large rocks and impurities from qualified particle sizes in the raw ore, preventing large materials from entering the crusher and causing equipment blockage or excessive wear. In metal mining (such as iron and copper ore), after the raw ore is mined from underground or open-pit mines, it often contains large rocks with a particle size exceeding 500mm. If these rocks are directly fed into a jaw crusher, it can cause blockage of the crusher's feed inlet, increased wear on the moving jaw, and even motor overload. In this case, a bar screen (mostly a "heavy-duty vibrating bar screen") will first perform coarse screening on the raw ore: the bars are made of manganese steel, with a gap set at 80-200mm (adjusted according to the crusher's feed requirements). Through high-frequency vibration of 1200-1500 times/minute, ore smaller than the gap (meeting the crusher's feed particle size) is screened through and conveyed to the crushing process, while large rocks larger than the gap are intercepted and transported by conveyor belt to secondary crushing or waste disposal. Data from an iron ore project shows that after equipping the machine with heavy-duty bar screens, the frequency of crusher blockages decreased from 8 times per month to 1 time per month, the lifespan of the moving jaw increased from 3 months to 8 months, annual maintenance costs decreased by 600,000 yuan, and crushing efficiency increased by 30%.

In non-metallic mineral processing (such as limestone and granite), bar screens are used for "ore pre-classification," separating qualified particle sizes in advance and reducing ineffective crushing. Taking limestone aggregate production as an example, the raw ore exhibits significant particle size variations after blasting. Particles between 20-80mm already meet the standards for coarse aggregate used in construction and do not need to enter the crusher. Through a bar screen (with an 80mm gap), particles larger than 80mm can be directly retained for crushing, while particles between 20-80mm are used directly as finished aggregate, and finer particles below 80mm are then subjected to subsequent screening and grading. This "pre-selection and grading" mode reduces crusher throughput by 40% and energy consumption by 25%, while simultaneously increasing finished aggregate production. After implementation, a limestone processing plant saw an increase of 150,000 tons of coarse aggregate annually, resulting in a 20% increase in overall revenue.

2. Construction Industry: Coarse Sorting of Construction Waste Facilitates Resource Recycling

With the advancement of the "construction waste resource utilization" policy, bar screens have become the "front-end sorting core" of construction waste processing lines. They are primarily used to separate large impurities from recyclable aggregates in construction waste, laying the foundation for subsequent recycling. Construction waste (such as discarded concrete blocks, bricks, steel bars, and wood) is transported to the processing plant and first undergoes coarse separation using a bar screen. The bar spacing is set to 50-100mm. Concrete fragments and brick particles smaller than the spacing pass through the vibrating screen and proceed to subsequent magnetic separation (for separating steel bars) and fine crushing processes to produce recycled aggregate. Larger impurities (such as discarded door and window frames, wood, and large concrete blocks) are retained. After manual sorting to remove recyclable materials such as wood and metal, the large concrete blocks are returned to the crusher for secondary crushing.

Data from a construction waste recycling project shows that equipping the system with a bar screen increases the processing efficiency of the subsequent magnetic separation equipment by 45% (eliminating the need to handle large impurities), and the purity of the recycled aggregate increases from 75% to 92% (reducing impurity content), meeting the requirements of the "Technical Specification for the Application of Recycled Aggregate from Construction Waste" and allowing for direct use in concrete blocks and road base paving. Meanwhile, the bar screen achieves a 98% rejection rate for large impurities, preventing large pieces of metal and wood from entering the fine crusher. This extends the lifespan of the fine crusher blades from one month to three months and reduces maintenance costs by 67%.

3. Metallurgical Industry: Pre-screening of Raw Materials to Ensure Stable Smelting Processes

In the metallurgical industry, bar screens are used for "pre-screening and impurity removal of smelting raw materials." This removes large impurities and foreign objects from the raw materials, ensuring that the raw materials entering the smelting furnace have uniform particle size and meet purity standards, thus avoiding impacts on smelting efficiency or damage to the furnace body. In steel smelting scenarios, raw materials such as iron ore and coke may become contaminated with large pieces of coal gangue, metal fragments, and soil clumps during transportation and storage. If these impurities enter the blast furnace, they can reduce the permeability of the furnace bed, affecting smelting reaction efficiency and even causing furnace wall calving. At this stage, bar screens (mostly "high-temperature resistant bar screens") are used for pre-screening of raw materials before they enter the blast furnace. The bars are made of heat-resistant steel (capable of withstanding temperatures above 600℃), with a gap of 30-50mm. Through low-speed vibration (800-1000 times/minute), raw materials smaller than the gap pass through the screen and are conveyed to the blast furnace, while impurities and lumps larger than the gap are intercepted and cleaned. After application in a steel plant, the blast furnace's material permeability increased by 15%, the smelting cycle was shortened by 8%, the coke ratio (the ratio of coke to iron ore) decreased by 5kg/t, and annual coke consumption costs were saved by over 1 million yuan.

In non-ferrous metal (such as copper and aluminum) smelting, bar screens are used as "coarse screening before ore flotation," separating large gangue (useless minerals in the ore), reducing the amount of gangue entering the flotation machine, and improving flotation efficiency and concentrate grade. Data from a copper mine flotation workshop shows that after equipping the flotation machine with bar screens, the processing load of the flotation machine decreased by 20%, the copper concentrate grade increased from 20% to 23%, the copper content in tailings decreased by 0.3%, and the annual copper concentrate production increased by 500 tons.

4. Coal Industry: Pre-screening and Desulfurization of Raw Coal to Improve Coal Quality

In the coal industry, bar screens are used for "pre-screening, grading, and desulfurization of raw coal," separating large pieces of gangue (high-sulfur impurities) from qualified raw coal, improving coal quality, and reducing the cost of subsequent coal washing processes. After raw coal is mined, it often contains large pieces of gangue with a particle size exceeding 300mm. These gangue not only have a high sulfur content (leading to excessive sulfur dioxide emissions during combustion), but also increase the processing load of the coal washing machine. At this stage, the bar screen (mostly a tensioned bar screen) pre-screens the raw coal: the bar gap is set to 50-100mm. Through the tensioning and relaxing vibration of the screen body (alternating tension and relaxation), raw coal smaller than the gap passes through the screen and enters the coal washing process, while large pieces of gangue larger than the gap are intercepted and collected in the gangue bin for use in roadbed filling or brick making.

Data from a coal mine washing plant shows that after equipping the coal washing machine with a tensioned bar screen, the processing capacity increased by 35% (without needing to handle large pieces of gangue), coal washing water consumption decreased by 20%, and the sulfur content of the coal decreased from 2.5% to 1.8%, meeting the national environmental protection emission standards (sulfur content of coal ≤2%). Simultaneously, the recovery rate of large pieces of gangue reached 95%, reducing the annual gangue landfill volume by approximately 50,000 tons, thus reducing environmental pressure and landfill costs.

Typical Features of Bar Screens:

Adapting to Coarse Screening Needs and Creating Differentiated Technological Advantages

The key to the core position of bar screens in coarse screening and pretreatment scenarios lies in their unique structural design and performance characteristics. They address the pain points of ordinary screening equipment when handling large, high-hardness, and impurity-containing materials, meeting the stringent requirements of industrial production for front-end pretreatment.

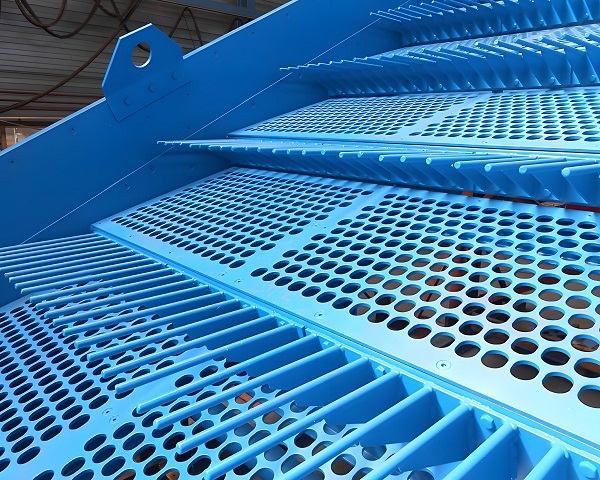

1. Robust and Wear-Resistant Structure, Adaptable to High-Hardness Materials

The core advantage of bar screens lies in their "strong wear resistance." Their screen surface is composed of parallel metal bars, often made of high-manganese steel (Mn13, Mn18), wear-resistant alloy steel, or tungsten carbide coated materials. The hardness can reach HRC50-60, far exceeding that of ordinary screens (such as low-carbon steel screens HRC20-30), enabling them to withstand the impact and friction of large, high-hardness materials (such as ores and rocks). In mining applications, when handling granite with a Mohs hardness of 7, manganese steel bars can last 1-2 years, while ordinary screens only last 1-2 months, representing a service life increase of more than 10 times.

Furthermore, the bar structure design further enhances wear resistance: some bars adopt a trapezoidal cross-section, narrow at the top and wide at the bottom, ensuring precise spacing between bars while increasing the wear-resistant surface area of the material contact surface; others are coated with a tungsten carbide coating, with a thickness of 0.5-1mm, further improving wear resistance by 50% compared to pure manganese steel bars. Comparative data from a metal mining project shows that the annual replacement cost for tungsten carbide-coated bar screens is only 20,000 yuan, while the annual replacement cost for uncoated ordinary manganese steel bar screens reaches 80,000 yuan, reducing maintenance costs by 75%.

2. Adjustable screen gap to adapt to various particle size coarse screening needs. The bar screen's screen surface consists of detachable and adjustable bars. By changing the gap between the bars, it can adapt to the coarse screening needs of different industries and materials, offering far greater flexibility than ordinary screens with fixed apertures. In practical applications, the bar gap can be flexibly adjusted within the range of 20-500mm according to the feeding requirements of subsequent equipment or the characteristics of the material: 80-200mm for processing raw ore; 50-100mm for processing construction waste; and 50-80mm for processing coal.

The adjustment method is also extremely convenient: some bar screens use a "bolt-fixed bar" design, allowing the bars to be moved by loosening the bolts, adjusted, and then retightened; others use "modular bar assemblies," allowing for quick replacement of bar assemblies with different gaps, reducing replacement time from 4 hours for traditional screens to 1 hour. A construction waste processing plant successfully adapted to the production needs of recycled aggregates, changing from "coarse aggregate" to "medium aggregate," by adjusting the gap between the bars (from 80mm to 50mm). This achieved product specification switching without replacing equipment, increasing equipment utilization by 40%.

3. Anti-clogging design, suitable for materials containing impurities and stickiness. Ordinary screening equipment (such as vibrating screens) is prone to screen clogging problems when processing materials containing impurities and slight stickiness (such as soil or fiber impurities stuck in the screen holes), requiring frequent shutdowns for cleaning. Bar screens, through their unique structural design, effectively solve this clogging problem: firstly, the gap between the bars is "linear," rather than the "pore structure" of traditional screens, making it less likely for impurities to get stuck; secondly, most bar screens are equipped with a "vibrating cleaning device," which shakes off sticky materials adhering to the bar surface through high-frequency vibration of the screen body or small oscillations of the bars themselves, preventing accumulation and clogging.

When processing wet ore with a moisture content of over 20%, ordinary vibrating screens require shutdown for cleaning every 2 hours to remove blockages, while bar screens can operate continuously for over 12 hours, reducing the cleaning frequency by 83%. When processing construction waste containing fibrous impurities (such as wood chips and plastic rope), the linear gaps of the bar screen allow these impurities to be intercepted and discharged along with larger pieces of material, preventing screen clogging and ensuring stable screening efficiency. Data from a limestone processing plant shows that the clogging failure rate of the bar screen is only 3%, while that of the ordinary vibrating screen reaches 25%, effectively reducing downtime and improving the continuous operation capability of the production line.

4. Large throughput, high efficiency, suitable for large-scale production. Bar screens have a large screen area (typically 5-20㎡) and large bar gaps, resulting in low material resistance during screening. The throughput is far higher than that of ordinary screening equipment of the same specifications, meeting the needs of large-scale production scenarios such as mining and construction. Taking the "heavy-duty vibrating bar screen" as an example, a single unit can process 200-1000 tons of material per hour, which is 2-5 times that of a vibrating screen of the same specification (processing capacity 50-200 tons/hour). In large-scale open-pit iron ore projects, three bar screens operating in parallel can process up to 40,000 tons of raw ore per day, fully meeting the feeding needs of five subsequent jaw crushers and ensuring the continuous and efficient operation of the production line.

Meanwhile, the bar screen has stable screening efficiency and is less affected by material moisture and particle size fluctuations. When processing mixed materials with large particle size differences, the "layered screening" effect of the bar screen is significant: large pieces of material move quickly above the screen surface and are intercepted, while small pieces of material pass through the screen quickly, achieving a screening efficiency (pass rate of qualified material) of 85%-95%, which is 10 percentage points higher than that of ordinary vibrating screens (75%-85%). After implementation at a coal washing plant, the efficiency of raw coal pre-screening increased by 15%, the processing pressure in the coal washing process was significantly reduced, and the overall production line capacity increased by 20%.

5. Stable operation, simple maintenance, and reduced overall costs: Bar screens have few moving parts and a simple structure, resulting in a low failure rate during operation and significantly lower maintenance costs compared to complex screening equipment. Structurally, the core components of a bar screen are only the bars, vibrating motor, and support springs, without complex transmission mechanisms. Routine maintenance only requires checking bar wear, tightening bolts, and lubricating motor bearings. The maintenance process is simple and requires no specialized technicians. Data from a mining project shows that the monthly maintenance time for a bar screen is only 2 hours, while the monthly maintenance time for a conventional vibrating screen reaches 8 hours, improving maintenance efficiency by 75%.

Furthermore, bar replacement costs are low and replacement is easy: a single bar is lightweight (typically 5-10 kg), allowing for manual replacement without the need for hoisting equipment; and since bar wear is localized, there is no need to replace the entire screen surface, only the severely worn bars need to be replaced, reducing replacement costs by 60% compared to replacing the entire screen. In a certain construction project, the annual maintenance cost of a bar screen was only 30,000 yuan, while the annual maintenance cost of a vibrating screen with the same processing capacity reached 120,000 yuan, demonstrating a significant overall cost advantage.

Bar screens, with their core functions of coarse screening, impurity interception, and equipment protection, are indispensable in pretreatment processes across multiple industries. Their wear resistance, adjustable gap, and anti-clogging features address many pain points of traditional screening equipment, significantly reducing overall costs. As industries demand higher pretreatment precision, bar screens will be further upgraded towards intelligent features (such as automatic gap adjustment) and high-wear-resistant materials, continuously providing strong support for cost reduction, efficiency improvement, and production process optimization across various industries.

Save Time! Get A Detailed Quotation Quickly.