Shaftless screw conveyors are a new type of continuous conveying equipment. Compared to traditional shafted screw conveyors, their core feature is the elimination of the central drive shaft, using an integral, flexible steel screw as the conveying core. With its unique structural design, it exhibits irreplaceable advantages in conveying easily entangled, highly viscous, and impurity-containing materials, and is widely used in environmental protection, chemical, food, mining, and other industries. This article will elaborate on its working principle and comprehensively analyze its core advantages, providing a reference for industry applications.

The working principle of a shaftless screw conveyor is based on the fundamental principle of screw drive, combined with the structural characteristics of its shaftless design, to achieve continuous and stable material conveying. Its core working process can be divided into three stages: power transmission, material drive, and auxiliary support. These stages work together to ensure conveying efficiency and stability.

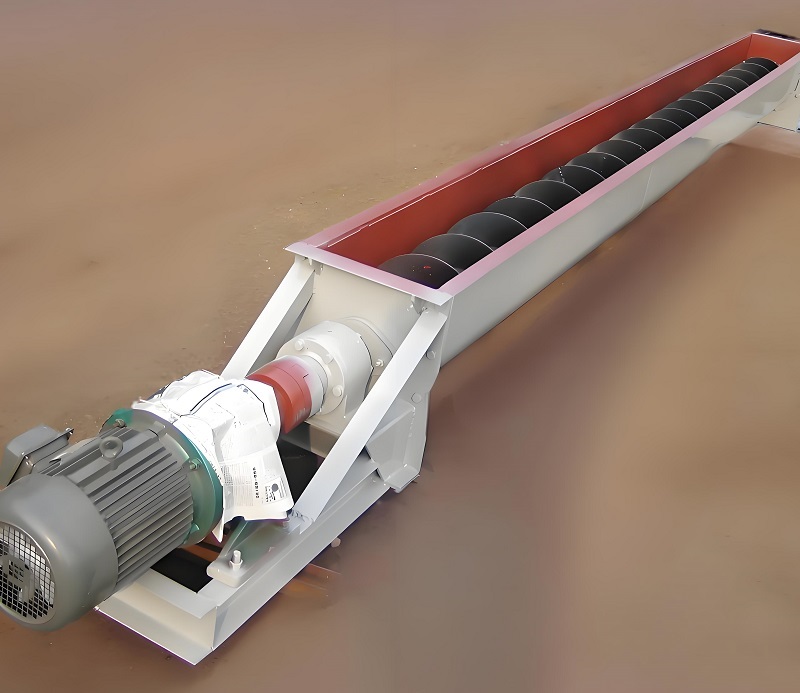

Power transmission is the foundation of the conveying operation. The drive unit of the equipment typically consists of an electric motor and a reducer. Common reducer types include cycloidal pinwheel reducers or shaft-mounted hardened gear reducers. In the design, the drive unit is usually located at the discharge end, so that the screw is under tension during operation, improving operational stability. The power output from the electric motor is reduced in speed and torque by a reducer before being transmitted to the shaftless screw conveyor, driving it to rotate at a constant speed. This provides continuous power for material conveying, with a torque reaching 4000 N/m, sufficient to meet the conveying requirements of high-resistance materials.

Material driving is the core operating process, similar in principle to a "rotating bolt pushing a nut." The shaftless screw conveyor acts as the bolt, and the material as the nut. As the screw conveyor rotates continuously, the material moves axially with it. Unlike shafted screw conveyors, shaftless screw conveyors have no central shaft interference. The screw is composed of thick, ribbon-like blades with a degree of flexibility, making slight contact and sliding against the lining plate at the bottom of the casing during rotation. The friction and axial thrust generated by the contact between the screw blades and the material force the material to move along the U-shaped or O-shaped trough towards the discharge port. Simultaneously, the material's own weight and the supporting force of the trough lining ensure that the material does not rotate synchronously with the screw during conveying, achieving continuous and stable transport. During the conveying process, a protective layer forms between the screw blades and the liner, reducing direct friction between the screw and the liner and extending the equipment's service life.

Auxiliary support relies primarily on the equipment's structural design to ensure smooth and safe conveying. The casing features a fully enclosed design, with an optional rainproof cover to effectively prevent material leakage and dust spread. The trough liner uses wear-resistant plastic, rubber, or cast stone materials to reduce wear on the equipment. The thrust bearing at the head effectively withstands the axial force generated during material conveying, preventing damage to equipment components. Furthermore, the equipment can be designed for bottom or end discharge, flexibly adapting to different working conditions.

Compared to traditional shafted screw conveyors and belt conveyors, shaftless screw conveyors, with their unique design without a central shaft, offer significant advantages in structure, performance, and application scenarios, which can be summarized as follows:

Strong anti-winding properties, less prone to clogging, and suitable for conveying complex materials. This is the most prominent advantage of shaftless screw conveyors. By eliminating the central drive shaft, they avoid clogging problems caused by ribbon-like, fibrous, and sticky materials entangled on the shaft. They are particularly suitable for conveying easily entangled materials such as screenings from wastewater treatment plants, filter press cake, kitchen waste, and textile waste, as well as highly viscous paste-like and semi-fluid materials. Simultaneously, the shaftless design allows for a higher material filling rate within the tank, reduces the likelihood of discharge port blockage, and enables stable low-speed operation, further reducing the risk of clogging, minimizing downtime for cleaning, and improving production efficiency.

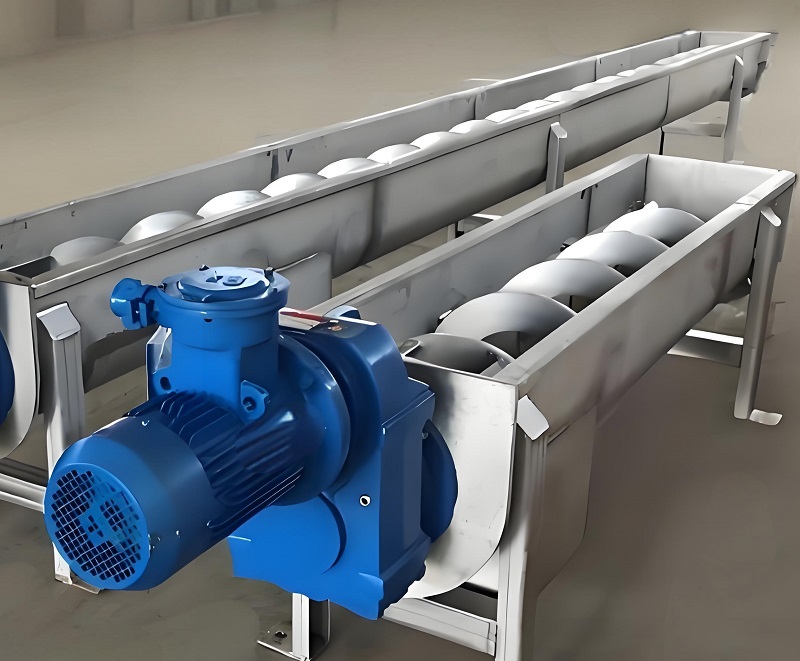

Excellent environmental performance, meeting stringent environmental standards. The equipment adopts a fully enclosed conveying structure, combined with an easy-to-clean screw surface, ensuring no leakage or contamination of materials during transport. This prevents material from being contaminated by the external environment and avoids the spread of dust and odors from the materials, protecting the working environment and the health of operators. This design makes it particularly suitable for industries with high hygiene and environmental requirements, such as food, pharmaceuticals, and chemicals. Examples include conveying sauces and fermented dough in food processing, and conveying corrosive and volatile materials in the chemical industry, effectively meeting industry compliance requirements.

High conveying efficiency, low energy consumption, and outstanding economic benefits. The conveying capacity of the shaftless screw conveyor is 1.5 times that of the traditional shafted screw conveyor of the same diameter. A single unit can convey up to 60 meters in length, and it can also be installed in series in multiple stages to achieve ultra-long-distance material conveying. Simultaneously, because materials are less prone to clogging, the equipment can operate smoothly at lower speeds with low frictional resistance, resulting in lower energy consumption compared to traditional equipment; in some scenarios, energy consumption can be reduced by more than 30%. Furthermore, the equipment has a compact structure with fewer parts and no easily damaged components such as hanging bearings, reducing weight and manufacturing costs compared to shafted models of the same specifications. It is easy to operate, economical, and durable, reducing equipment procurement and maintenance costs.

Wide adaptability and flexible installation make it suitable for multiple industries and scenarios. The shaftless screw conveyor is highly adaptable to materials, capable of conveying various forms of materials such as powders, granules, lumps, pastes, and semi-fluids. Whether it's highly abrasive mineral sands and fly ash, or highly viscous asphalt and resins, it can achieve smooth conveying. In terms of installation, it can be installed horizontally or inclined (angle ≤20°), with a compact structure and small footprint, saving space, making it particularly suitable for space-constrained scenarios such as pipeline interlayers in chemical plants and confined workshops in sewage treatment plants. Furthermore, by selecting different materials (stainless steel, carbon steel, fiberglass, etc.), it can adapt to special working conditions such as high temperatures and corrosion. For example, the spiral blades with tungsten carbide coating can withstand temperatures above 200℃, meeting the conveying needs of high-temperature materials such as fermented biomass.

Maintenance is convenient, operation is stable, and service life is long. The shaftless screw conveyor has a relatively simple structure, mainly composed of a drive unit, screw body, casing, and liners. With fewer parts, daily maintenance mainly focuses on the inspection and replacement of liners and spiral blades, making operation simple. The trough uses segmented flange connections, and the liners can be disassembled and replaced individually without disassembling the entire equipment, reducing maintenance difficulty and cost. Meanwhile, the equipment operates smoothly with minimal vibration and noise. The screw body is made of high-strength alloy steel strip, cold-rolled in one piece without welds, resulting in high overall rigidity and wear resistance. Combined with wear-resistant liners, this effectively extends the equipment's service life.

The shaftless screw conveyor, through its innovative design without a central shaft, breaks through the limitations of traditional conveying equipment. Its working principle is scientifically simple, offering significant advantages in anti-winding, environmental protection, high efficiency, and energy saving. It effectively solves the pain points of conveying easily tangled and highly viscous materials. With increasingly stringent environmental standards and rising requirements for conveying equipment across industries, the shaftless screw conveyor, with its wide adaptability and superior performance, will see even wider applications in municipal environmental protection, chemical, food, and mining industries, providing strong support for improving production efficiency and achieving environmental compliance in these sectors.

Save Time! Get A Detailed Quotation Quickly.