Vertical balers are widely used small and medium-sized compression equipment in the waste treatment and recycling industry. Thanks to their compact structure, convenient operation, and controllable costs, they have become the preferred equipment for small and medium-sized waste treatment plants, communities, shopping malls, schools, and waste recycling stations. Compared to horizontal balers, vertical balers use vertical compression as their core working method, suitable for compressing and forming loose waste and small waste materials. This not only reduces waste volume and facilitates storage and transportation, but also lowers equipment investment and operating costs, meeting the waste treatment needs of small and medium-sized scenarios. This article, combining the structural principles and on-site application scenarios of vertical balers, comprehensively analyzes their core advantages and significant features, supplemented with practical details, providing comprehensive technical references for equipment selection, use, and maintenance, and assisting relevant scenarios in efficiently carrying out waste treatment and resource recycling work.

I. Core Advantages of Vertical Balers

The advantages of vertical balers revolve around four core aspects: "suitable for small and medium-sized scenarios, efficient and convenient, controllable costs, and safe and reliable." They accurately address the pain points of small and medium-sized scenarios, such as small waste treatment volume, limited space, and insufficient operator expertise, complementing horizontal balers and possessing irreplaceable advantages in specific scenarios. These advantages can be divided into the following five aspects:

1. Compact structure, small footprint, suitable for multi-scenario installation

The compact structure is the most prominent advantage of vertical balers. The core reason is that the equipment adopts a vertical structural design, with high integration of core components such as the motor, hydraulic system, baling chamber, and press head. There is no long horizontal machine body, resulting in a small overall volume and a footprint that is only 1/3 to 1/2 of that of a horizontal baler with the same processing capacity. Typically, small vertical balers require only 1-2 m² of space, and medium-sized equipment requires no more than 3 m², eliminating the need for large areas and allowing for flexible installation in various scenarios, including indoors and outdoors. This is especially suitable for small and medium-sized waste treatment points with limited space, community waste transfer stations, and shopping mall basement waste rooms. Unlike horizontal waste balers which require a separate concrete foundation, vertical waste balers are lighter (typically between 500kg and 5 tons) and do not require complex foundation construction. Installation is simple, requiring only placement on a flat, hard, paved surface with anti-slip and shock-absorbing mats. This significantly reduces the difficulty and cost of site preparation. Furthermore, their compact size facilitates handling and relocation. If the site layout changes later, the equipment can be quickly moved using simple equipment such as forklifts, offering great flexibility and avoiding the drawbacks of fixed installations. This adaptability meets the dynamic needs of various scenarios.

2. Easy to operate, low learning curve, no need for professional operators

Vertical waste balers are designed to accommodate the varying skill levels of operators in small and medium-sized settings. The overall operation process is simple and easy to understand, with a very low learning curve. No professional technical training is required; ordinary staff can operate the equipment independently after a brief explanation, significantly reducing labor and training costs. The equipment control system features a user-friendly design, mostly using manual button controls, with some medium-sized models offering an upgrade to semi-automatic control. The core operation involves only four steps: feeding, starting compression, pressure holding, and discharge. The process is simple, without complex parameter settings or operating procedures.

During operation, the operator only needs to manually or via a simple conveyor belt feed loose waste (such as waste paper, plastic bottles, and household waste) into the baling chamber. After closing the feeding door, pressing the compression button automatically completes waste compression and pressure molding. After molding, pressing the discharge button automatically releases the baled waste or allows for manual removal. The entire process requires no complex operations. The equipment is also equipped with clear indicator lights and meters to display the equipment's operating status in real time (such as hydraulic pressure and operating faults). Operators can quickly assess the equipment's status and address simple anomalies promptly, without relying on professional technicians, further enhancing ease of operation.

3. Low investment cost, high cost-effectiveness, suitable for small and medium-sized budgets

The equipment investment, operating costs, and maintenance costs of vertical waste balers are significantly lower than those of horizontal waste balers with the same processing capacity. They offer excellent cost-effectiveness, precisely meeting the budget requirements of small and medium-sized scenarios, making them an economical choice for small and medium-sized waste treatment and recycling applications. In terms of equipment investment, the market price of small vertical waste balers is typically between 10,000 and 50,000 RMB, while medium-sized equipment costs between 50,000 and 150,000 RMB. This is only 1/4 to 1/2 the price of horizontal balers with the same processing capacity, significantly lowering the equipment procurement threshold and allowing small and medium-sized enterprises, communities, and waste recycling stations with limited budgets to achieve waste compression and improve waste treatment efficiency.

In terms of operating costs, vertical waste balers have lower power consumption (usually between 1.5 and 11 kW), with an hourly power consumption of only 2-10 kWh, far lower than horizontal balers (which typically consume 10-30 kWh per hour). At the same time, the equipment's hydraulic and electrical systems have a simple structure, resulting in lower consumption of hydraulic oil and wear parts (such as seals and liners), and less frequent replacement, further reducing operating costs. In terms of maintenance costs, the simple structure and fewer core components of the equipment make maintenance easy, requiring no professional maintenance personnel. Ordinary staff can perform daily cleaning, lubrication, and replacement of wear parts. Annual maintenance costs are only a few thousand RMB, far lower than those of horizontal balers, resulting in significant long-term savings.

4. Low energy consumption, low pollution, and alignment with green and environmentally friendly concepts

With increasingly stringent environmental requirements, the energy-saving and environmentally friendly performance of waste treatment equipment is becoming more important, and vertical waste balers have significant advantages in this regard. The equipment uses a low-power motor drive, resulting in lower energy consumption. Compared to horizontal balers, it can save 30%-50% of electricity consumption for the same processing capacity. Long-term operation can significantly reduce energy consumption and carbon emissions, aligning with energy-saving and emission reduction environmental requirements. At the same time, the equipment uses a closed baling chamber design, preventing waste scattering and dust dispersion during the compression process, effectively reducing pollution to the surrounding environment. This makes it particularly suitable for indoor installation, avoiding impact on the surrounding environment and personnel health. Vertical waste balers are primarily used for compressing loose waste and recyclable materials, reducing waste volume by 3-5 times. This reduces waste storage space and transportation frequency, thereby minimizing pollution problems such as exhaust emissions and waste leakage during transportation. Simultaneously, the compressed bales (such as waste paper bales and plastic bales) are easy to recycle, enabling resource regeneration and aligning with the "reduction, resource utilization, and harmlessness" concept of waste management, contributing to green and environmentally friendly development. For easily perishable waste such as food waste and wet waste, some vertical balers can be equipped with anti-corrosion liners and sealing devices to reduce odor leakage and further enhance environmental performance.

5. Stable operation, low failure rate, and convenient maintenance

Vertical waste balers have a simple structure, with core components including only the motor, hydraulic pump, hydraulic cylinder, baling chamber, and control cabinet. They lack complex transmission structures and auxiliary systems, resulting in fewer parts and simpler interconnections. Therefore, they offer strong operational stability, extremely low failure rates, and can operate continuously for extended periods, meeting the waste management needs of small and medium-sized facilities. The equipment's hydraulic system is optimized, using high-quality hydraulic valves and seals, ensuring good sealing performance and preventing hydraulic oil leakage. The electrical system features a waterproof and dustproof design with strong insulation, effectively preventing faults such as leakage and short circuits, adapting to various working environments.

Furthermore, equipment maintenance is simple and convenient. Routine maintenance only requires cleaning the equipment, replenishing hydraulic oil, and inspecting and replacing wear parts. No complex repair tools or professional skills are needed; ordinary personnel can perform the maintenance. For example, replacing wear parts such as seals and liners only takes 10-30 minutes, and hydraulic oil replacement is required every 3-6 months. The maintenance process is simple and does not affect the normal operation of the equipment. If simple faults occur (such as insufficient pressure or inability to start), operators can quickly troubleshoot the problem using indicator lights and meters, resolving the issue promptly without contacting manufacturer technicians, significantly reducing equipment downtime and improving waste processing efficiency.

II. Significant Features of Vertical Waste Balers

The features of vertical waste balers are closely related to their structural design and working principles. In addition to the core advantages mentioned above, they also possess unique compression methods, wide material compatibility, reliable safety performance, and an aesthetically pleasing design, further enhancing the equipment's practicality and adaptability. These features can be divided into the following six aspects:

1. Unique Compression Method, Moderate Baling Density, and Excellent Forming Effect

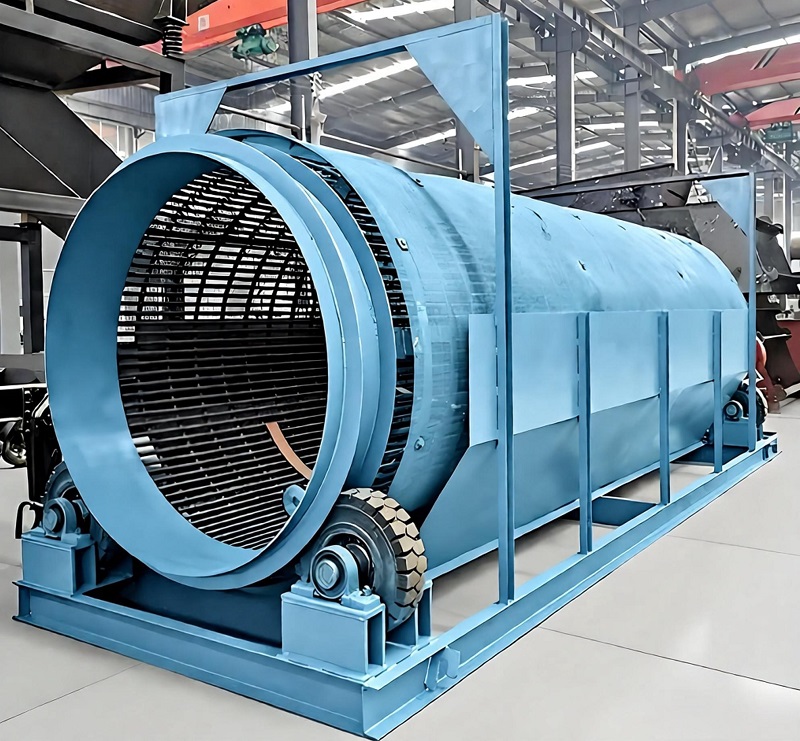

Vertical waste balers utilize a vertical compression method, with the press head compressing the waste in the baling chamber from top to bottom. The compression force is uniform, effectively compressing loose waste to achieve a moderate baling density, typically between 0.5-1.0 t/m³. This not only reduces waste volume but also ensures excellent baling block formation, without loosening or cracking, facilitating storage and transportation. Compared to the horizontal compression of horizontal balers, vertical compression is more suitable for compressing loose, lightweight waste, preventing issues such as shifting and clumping during the compression process. The baling blocks are uniform in size and regular in shape (mostly square or rectangular), making them easy to stack and store, reducing storage space requirements.

At the same time, the equipment's compression pressure can be flexibly adjusted according to the material type (usually between 5-20 MPa). For materials of different hardness (such as waste paper, plastic, and household waste), the corresponding compression pressure and holding time can be adjusted to ensure optimal baling and forming results. For example, when processing lightweight recyclable waste such as waste paper and plastic bottles, the compression pressure can be appropriately increased to improve baling density, facilitating recycling and transportation; when processing easily perishable waste such as household waste and kitchen waste, the compression pressure can be appropriately reduced to prevent excessive compression that could lead to leakage of liquids and environmental pollution.

2. Wide Material Compatibility, Strong Specificity, and Adaptability to Multiple Types of Waste Treatment

Although vertical waste balers are primarily used in small and medium-sized settings, they are compatible with a wide range of materials and can handle various types of loose waste and recyclable materials. Their strong specificity allows them to meet the waste treatment needs of different scenarios. The main materials compatible with this equipment include: recyclable waste (such as waste paper, cardboard boxes, plastic bottles, plastic film, used clothing, aluminum cans, etc.), household waste (such as kitchen waste, fruit peels, paper scraps, plastic bags, etc.), and industrial scraps (such as small plastic scraps, fabric scraps, paper scraps, etc.), covering various types of waste commonly found in small and medium-sized settings.

Different types of vertical waste balers are specifically designed for different materials. For example, small vertical balers (tonnage ≤ 10t) are mainly suitable for lightweight recyclable waste such as waste paper and plastic bottles, and a small amount of household waste, with a small processing capacity (0.5-2 tons per hour); medium-sized vertical balers (tonnage 10-30t) can handle a wider range of waste types, including household waste, kitchen waste, and industrial scraps, with a moderate processing capacity (2-5 tons per hour), meeting the waste treatment needs of small waste transfer stations and large communities. At the same time, the equipment can be equipped with different materials for the lining plates (such as ordinary steel plates, anti-corrosion lining plates) according to the type of material, improving the adaptability and service life of the equipment.

3. Reliable safety performance and comprehensive protective measures to prevent safety accidents

The vertical waste baler places great emphasis on operational safety and is equipped with comprehensive safety protection measures to effectively prevent safety accidents and ensure the personal safety of operators and equipment safety. The equipment's feeding and discharge doors are equipped with safety locking devices. The equipment can only start the compression process when the doors are completely closed and locked, preventing the doors from accidentally opening during operation, which could lead to waste scattering or operator injury; at the same time, the doors are equipped with observation windows, allowing operators to observe the waste compression situation in the baling chamber in real time without opening the doors, further improving operational safety. In addition, the equipment is equipped with safety devices such as an emergency stop button, overload protection, and pressure protection. The emergency stop button is installed in a conspicuous and easily accessible location. If the equipment malfunctions, the operator can immediately press the emergency stop button to cut off the power and stop the equipment. The overload protection device can automatically cut off the power when the equipment is overloaded, preventing damage to the motor and hydraulic system. The pressure protection device can automatically release pressure when the hydraulic system pressure is too high, preventing hydraulic pipes and cylinders from rupturing and ensuring safe operation of the equipment. At the same time, the electrical system of the equipment adopts an insulated protection design to avoid safety hazards such as leakage and short circuits, making it suitable for different working environments.

4. Beautiful appearance, low noise, suitable for indoor installation

The vertical waste baler adopts an integrated design with a simple and beautiful appearance. The machine body is mostly treated with powder coating, resulting in a smooth and clean surface. The color can be customized according to the scene requirements (such as gray, blue, green, etc.), allowing it to blend harmoniously with the surrounding environment. It is especially suitable for indoor installation, such as in shopping mall waste rooms, community waste rooms, and office building waste rooms, without affecting the aesthetics of the surrounding environment. Compared with horizontal balers, vertical balers have a cleaner body, without long pipes and components, resulting in a better visual effect and easier cleaning and maintenance.

At the same time, the equipment operates with low noise. Due to the use of a low-power motor drive and the inclusion of shock absorption and noise reduction devices, the operating noise is usually controlled between 60-75dB, far below the industry standard (≤85dB). It does not produce harsh noise, effectively reducing the impact on the surrounding environment and people. It is suitable for installation in densely populated areas such as communities, shopping malls, and schools, avoiding noise pollution. In addition, the equipment has low vibration during operation. By laying anti-slip and shock-absorbing mats, vibration can be further reduced, preventing damage to the ground and making it suitable for installation on indoor hardened floors.

5. Intelligent and upgradeable, adaptable to expanding application scenarios

With the development of technology, the intelligence level of vertical waste balers is constantly improving, and they can be upgraded and modified according to scene requirements to adapt to expanding application scenarios. The basic vertical waste baler uses manual control, making it easy to operate and suitable for small-scale applications; the medium-sized vertical waste baler can be upgraded to semi-automatic control, equipped with a simple conveyor belt and automatic feeding device, reducing manual labor and improving waste processing efficiency; the high-end vertical waste baler can be upgraded to fully automatic control, equipped with a PLC control system and touch screen operation panel, enabling automatic feeding, automatic compression, automatic pressure maintenance, and automatic discharge throughout the entire process, requiring no manual intervention, significantly improving waste processing efficiency and suitable for medium-sized waste transfer stations and other scenarios.

The equipment can be customized with various auxiliary functions as needed, such as waste sorting devices, odor treatment devices, and dust treatment devices, further enhancing its practicality. For example, in communities and shopping malls, an odor treatment device can be added to reduce odors generated during waste compression; in waste recycling stations, a waste sorting device can be added to facilitate the classification and compression of recyclable waste, improving recycling efficiency; in scenarios with high dust levels, a dust treatment device can be added to reduce dust pollution, adapting to the needs of more scenarios.

6. Long service life and outstanding cost-effectiveness, resulting in significant long-term benefits

The core components of the vertical waste baler are made of high-quality materials. Key components such as the motor, hydraulic pump, and hydraulic cylinder are selected from well-known brands, ensuring reliable quality, strong wear resistance, and a long service life. It typically operates normally for 5-8 years, and with proper maintenance, the service life can be extended to over 10 years, far exceeding that of ordinary small-scale waste treatment equipment. The equipment body is welded from high-quality steel plates, ensuring strong welding, high compressive strength, and wear resistance. It can withstand long-term compression loads without deformation or damage; wear parts such as liners and seals are made of wear-resistant and corrosion-resistant materials, reducing replacement frequency and further extending the equipment's service life.

Combined with its low equipment investment, operating costs, and maintenance costs, the vertical waste baler offers outstanding cost-effectiveness and significant long-term benefits. For small and medium-sized applications, adopting this equipment is a highly cost-effective solution.

Purchasing a vertical waste baler can quickly reduce waste volume, improve processing efficiency, and lower waste storage and transportation costs. It also enables the compression and recycling of recyclable waste, increasing recycling revenue. Furthermore, the equipment has low maintenance costs and a low failure rate, ensuring long-term stable operation without frequent equipment replacement, further reducing long-term investment. It is an ideal choice for waste treatment and resource recovery in small and medium-sized settings.

III. Summary of Application Scenarios for Vertical Waste Balers

The advantages and characteristics of vertical waste balers are precisely suited to small and medium-sized waste treatment scenarios. Its compact structure, convenient operation, controllable cost, stable operation, and environmental friendliness address the pain points of limited space, insufficient budget, low operator expertise, and low waste treatment efficiency in small and medium-sized settings. Its vertical compression, wide range of applicable materials, safety and reliability, aesthetically pleasing design, and potential for intelligent upgrades further enhance the equipment's practicality and adaptability, meeting the waste treatment needs of various scenarios such as communities, shopping malls, schools, recycling stations, small waste transfer stations, and industrial enterprises.

Compared to horizontal waste balers, vertical waste balers are more suitable for scenarios with smaller processing volumes, limited space, and insufficient budgets, primarily used for the compression and molding of loose waste and recyclable materials, emphasizing convenience and cost-effectiveness. Horizontal waste balers are more suitable for large-scale scenarios with large processing volumes, ample space, and sufficient budgets, focusing on processing efficiency and baling density. In the actual selection process, the model and configuration of the vertical waste baler can be reasonably chosen based on factors such as the waste processing volume, site size, budget, and material type, fully utilizing its advantages and characteristics to improve waste treatment efficiency, reduce processing costs, and promote the resource utilization, harmless treatment, and reduction of waste.

Save Time! Get A Detailed Quotation Quickly.