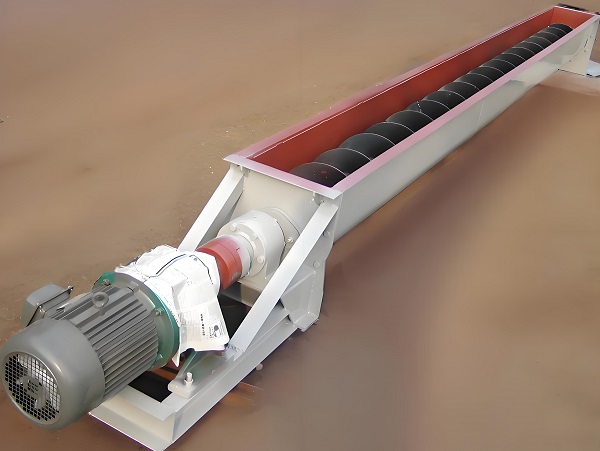

Shaftless screw conveyors, by eliminating the central drive shaft of traditional screw conveyors and adopting an innovative structural design that directly drives the material with spiral blades, have become a key conveying device for handling sticky, entangled, bulky, and other irregularly shaped materials. In diverse fields such as environmental wastewater treatment, mining, food processing, and construction, these devices, with their technical advantages of anti-clogging, easy cleaning, and strong adaptability, effectively address industry challenges such as material jamming, blockage, and difficulty in cleaning, often associated with traditional conveying equipment. They play an irreplaceable and important role in special material conveying scenarios.

1.Core Function: Structural Advantages that Break Through the Limitations of Traditional Conveyors

The functional characteristics of shaftless screw conveyors stem from their unique central shaftless structural design, significantly improving material adaptability and conveying stability compared to shafted screw conveyors.

Anti-entanglement and anti-clogging performance are their core technical advantages. Traditional shafted screw conveyors are prone to material entanglement, such as fibers, hair, and ropes, leading to equipment downtime due to material entanglement in the central shaft. Shaftless screw conveyors, however, eliminate this risk by directly connecting the spiral blades to the drive unit. This allows for efficient conveying of fiber-rich materials such as municipal sludge and papermaking waste. When handling sticky materials like distiller's grains and starch residue, the shaftless design reduces the contact area between the material and the conveyor. Combined with the continuous pushing action of the spiral blades, this effectively prevents material adhesion and accumulation, resulting in conveying efficiency improvements of over 30% compared to shafted systems.

The conveying capacity of large-particle materials is significantly enhanced. Traditional shafted screw conveyors, limited by the central shaft diameter, struggle to convey large materials exceeding one-third of the shaft diameter. However, shaftless screw conveyors, with their wider conveying channel, can easily handle large-particle materials up to 200mm in diameter, such as construction waste and mine tailings. Furthermore, the spiral blades are constructed of high-strength, wear-resistant alloy, offering excellent impact resistance and a service life of over 5,000 hours. The enclosed conveying design meets stringent environmental protection requirements. This equipment features a fully enclosed casing, with only the feed and discharge ports remaining. This effectively prevents dust leakage and odor spread when conveying dusty materials such as fly ash and cement powder, as well as odorous materials such as food waste and livestock manure. Test data shows that dust concentrations during operation can be controlled below 5mg/m³, fully complying with the relevant provisions of the "Comprehensive Emission Standards for Air Pollutants." This makes it particularly suitable for urban core areas with strict environmental protection requirements.

2. Environmental Protection Industry: The "Core Conveying Unit" for Polluted Material Processing

In the environmental protection industry, shaftless screw conveyors have become critical equipment in processes such as sewage treatment, solid waste disposal, and incineration.

In the sludge processing stage of sewage treatment plants, shaftless screw conveyors perform the crucial tasks of sludge transfer and dewatering. The concentrated sludge discharged from the primary settling tank has a moisture content of up to 97% and is extremely viscous. A shaftless screw conveyor smoothly conveys it to a plate and frame filter press for dewatering. The dewatered sludge cake (moisture content reduced to below 75%) is then transported by another shaftless screw conveyor to a sludge composting plant or incinerator. Some advanced equipment can also be directly integrated with a stacked screw dewatering machine, using a variable-speed motor to precisely control the conveying speed, achieving simultaneous dewatering and conveying operations, significantly improving sludge treatment efficiency.

In waste-to-energy projects, shaftless screw conveyors are primarily used for waste pretreatment and ash conveying. After shredding, the raw waste is transported by a shaftless screw conveyor to a drum screen for sorting. This equipment is designed to withstand impact from hard objects such as metal and glass, effectively preventing traditional conveyor belts from being scratched. After cooling, the slag produced by incineration is transported to the slag bin by a high-temperature shaftless screw conveyor (with a maximum temperature tolerance exceeding 300°C). The screw blades are made of heat-resistant steel to effectively resist high-temperature wear. In the food waste treatment sector, shaftless screw conveyors have successfully solved the challenge of conveying highly oily, wet materials. Because food waste contains large amounts of grease and food residue, which easily stick together and clump, conventional conveying equipment often experiences slippage and clogging during operation. However, shaftless screw conveyors utilize the forced propulsion of spiral blades to continuously transport materials to the hydrolysis tank. The inner surface of the housing features a polytetrafluoroethylene (PTFE) anti-stick coating, effectively reducing material residue and facilitating subsequent cleaning and disinfection, meeting food-grade hygiene standards.

3. Mining and Construction: A Wear-Resistant Conveying Solution for Highly Abrasive Materials

In the mining and construction industries, shaftless screw conveyors, with their excellent wear resistance and stable operation, are an ideal conveying solution for materials characterized by high hardness, high abrasion, and high impurities.

In the tailings treatment process of metal mines, shaftless screw conveyors are primarily used for conveying and dewatering tailings slurry. Tailings slurry contains a large number of fine ore particles, which can cause severe wear on conveying equipment. The shaftless screw conveyor's blades are cast from a high-chromium alloy with a hardness exceeding HRC55, effectively resisting slurry erosion. Furthermore, the equipment supports an inclined configuration (maximum tilt angle of 30°), allowing it to convey tailings slurry directly from the sedimentation tank to the dewatering screen without the need for additional lifting equipment, effectively saving site space.

In the construction waste sorting process, shaftless screw conveyors are primarily used to transport inert materials such as concrete blocks and brick and tile fragments. Because construction waste often contains debris such as rebar and wire, traditional shafted conveyors are prone to entanglement and jamming. Shaftless screw conveyors, however, can directly transport the contaminated materials and, through the rotation of the screw blades, transport them along with the inert materials to the sorting platform. For highly concentrated, viscous materials like construction mud, shaftless screw conveyors have a conveying capacity of 50-200 m³/h. The rounded bottom of the housing prevents material accumulation and ensures smooth conveying. In the shield machine (TBM) system used in tunnel construction, shaftless screw conveyors are a core component of the excavation system. The excavated soil produced by the shield machine is characterized by high moisture content, high viscosity, and inclusions of gravel. Shaftless screw conveyors can be installed directly on the rear of the shield machine, enabling continuous transport of this soil. Their compact design adapts to the confined spaces within the tunnel, and their anti-clogging function ensures uninterrupted excavation, effectively guaranteeing efficient tunneling.

4. Food and Chemical Industry: A Clean and Corrosion-Resistant "Specialized Conveying Tool"

In the food processing and chemical production sectors, shaftless screw conveyors, through upgraded materials and optimized structures, are perfectly adapted to meet the stringent requirements for cleanliness and corrosion resistance in conveying equipment.

In the food processing industry, shaftless screw conveyors are primarily used for raw material transportation and waste disposal. For example, in starch production, these devices are constructed of 304 stainless steel with a polished interior, enabling safe conveyance of materials such as starch slurry and potato residue, effectively preventing bacterial growth caused by residual material and fully complying with food hygiene standards. In the fruit and vegetable processing sector, this equipment can be used to convey washed fruit and vegetable residues. The clearance between the spiral blades and the housing is controlled to within 1mm, reducing residue adhesion and facilitating disassembly and cleaning, meeting the frequent cleaning requirements of the food processing industry.

In the chemical industry, shaftless screw conveyors are primarily used to transport corrosive materials and hazardous waste. For corrosive materials such as sulfuric acid slag and caustic soda solution, the equipment utilizes 316L stainless steel or plastic-lined materials, offering corrosion resistance over 10 times greater than that of ordinary carbon steel equipment. For hazardous waste treatment, such as waste paint residue and the residue left after the crushing of waste solvent barrels, the equipment utilizes a fully enclosed structure and is equipped with a nitrogen protection device to effectively prevent chemical reactions between the hazardous waste and air, ensuring production safety.

In the pharmaceutical industry, shaftless screw conveyors are used for solid waste treatment, transporting pharmaceutical residues and spent activated carbon. Because pharmaceutical residues contain high moisture content and drug residues, they require enclosed conveying to prevent environmental contamination. The fully enclosed design of the shaftless screw conveyor meets this requirement. The equipment also supports seamless cleaning, with a CIP (clean-in-place) system for efficient flushing of the housing and spiral blades, meeting Good Manufacturing Practice (GMP) certification standards.

5. Agriculture and Animal Husbandry: "Efficient Transfer Equipment" for Organic Materials

In agricultural production and livestock farming, shaftless screw conveyors, with their efficient conveying and easy maintenance, are the preferred material handling equipment for large volumes of highly viscous, fermentable organic materials.

In livestock and poultry manure treatment, shaftless screw conveyors play a crucial role in collecting and transporting manure. Manure from livestock and poultry, such as pig and chicken manure, is highly viscous and watery, making traditional scraper conveyors prone to clogging. Shaftless screw conveyors, however, can transport manure directly from the manure pit to the fermentation tank. The rotating motion of the spiral blades also provides initial agitation, facilitating subsequent anaerobic fermentation. Some equipment can be used in conjunction with a solid-liquid separator to transport the separated dry manure to a composting plant, realizing resource utilization. In straw comprehensive utilization projects, shaftless screw conveyors are primarily used to transport shredded straw. Shredded straw is approximately 5-10 cm long and fibrous, easily tangling and clogging the equipment. Shaftless screw conveyors, however, enable continuous conveyance of shredded straw, allowing direct delivery to biomass fuel pelletizers or silage pits without tangling. The equipment supports tilted conveying (with an angle of no more than 25°), flexibly adapting to different site layout requirements.

In grain processing, shaftless screw conveyors are used to transport by-products such as bran and rice bran. These by-products are fine particles that easily generate dust, and the fully enclosed structure of the shaftless screw conveyor effectively prevents dust from dispersing. The equipment operates smoothly, with noise levels kept below 70 decibels, minimizing noise pollution in the workshop environment. Furthermore, the variable frequency motor allows for adjustable conveying speeds between 0.5 and 1.5 m/s, allowing for flexible adjustments to feed rates based on the capacity of subsequent processing equipment.

6. Technology Upgrade: A Development Direction Adapting to Future Demands

As various industries increasingly demand higher performance from conveying equipment, shaftless screw conveyors are continuously evolving toward intelligent, large-scale, and multifunctional features, further expanding their application areas and technological boundaries.

Intelligent monitoring systems significantly improve equipment operation and maintenance efficiency. The new generation of shaftless screw conveyors integrates multiple sensors, including temperature, vibration, and torque, and utilizes IoT technology to enable real-time transmission and monitoring of operating data. When spiral blade wear reaches a set threshold or a blockage occurs within the conveyor casing, the system automatically issues an alert and shuts down the conveyor for protection. Some high-end equipment is also equipped with an AI-powered visual recognition system that accurately identifies foreign objects (such as metal lumps) in conveyed materials and promptly removes them with pneumatic baffles, effectively ensuring safe operation.

Large-scale and efficient designs meet the needs of large-scale production. For large-scale production applications such as mining and environmental protection, shaftless screw conveyors have conveying capacities exceeding 500 m³/h and casing diameters up to 1200 mm, enabling them to handle larger particle sizes. Furthermore, the dual-drive motor design provides greater conveying torque, enabling a single unit to convey up to 40 meters, meeting long-distance conveying needs while reducing the number of equipment connections and effectively lowering system failure rates.

Multifunctional integration expands the equipment's application scenarios. The new shaftless screw conveyor's integrated design enables multiple functions, including conveying, mixing, and heating. When conveying high-viscosity materials such as asphalt and resin, steam or hot oil heating can be applied through the casing jacket to prevent the material from cooling and solidifying. When handling organic materials, the spiral blades can be equipped with stirring teeth to achieve material mixing, eliminating the need for separate stirring equipment and effectively reducing equipment investment costs.

Save Time! Get A Detailed Quotation Quickly.